Component selectionDesign tips

Characteristics

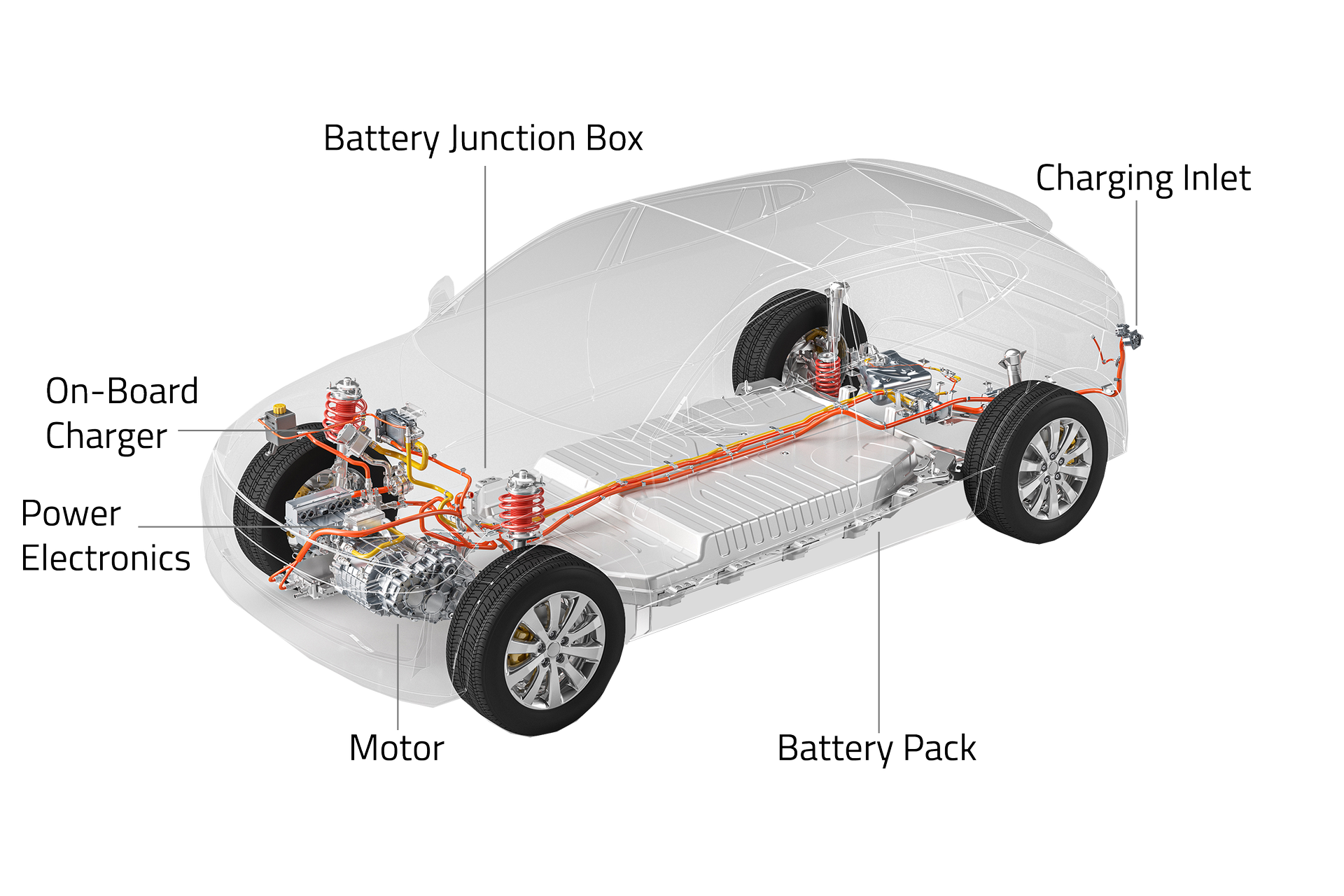

E-vehicles typically are offering two ways of recharging their batteries.

- High-voltage DC charging systems promise very short charging times. But these also require a very powerful power connection, which many households and businesses do not have.

- More widespread are 3-phase AC connections, which are often also available to private households.

Alternating current (AC) firstly has to be converted to direct current (DC) on board of an electric vehicle in order to charge the vehicle's battery. Power conversion brings up challenges in power handling and EMC.

Würth Elektronik is offering a growing range of automotive-certified products matching the following industry standards:

- AEC-Q 200 qualified products

- IATF 16949 certified production facilities

- PPAP Level 1-3

- IMDS, etc.

Top Sellers for On-Board Charger

WE-PDA SMT Shielded Power Inductor

Characteristics

- Magnetically shielded version

- High Saturation currents up to 23 A

- Very low self-losses at high switching frequency's

- Wide inductance spectrum available at all sizes

- Operating Temperature -40 °C up to +125 °C

WE-MAIA SMT Power Inductor

Characteristics

- Magnetic iron alloy

- Compact design

- Magnetically shielded

- Operating temperature range: -40°C up to +125°C

WE-CBA SMT EMI Suppression Ferrite Bead

Characteristics

- Reliable Ni-Sn electrodes

- High rated current up to 5 A

- Operating temperature: –55 ºC to +125 ºC

- Automotive approved

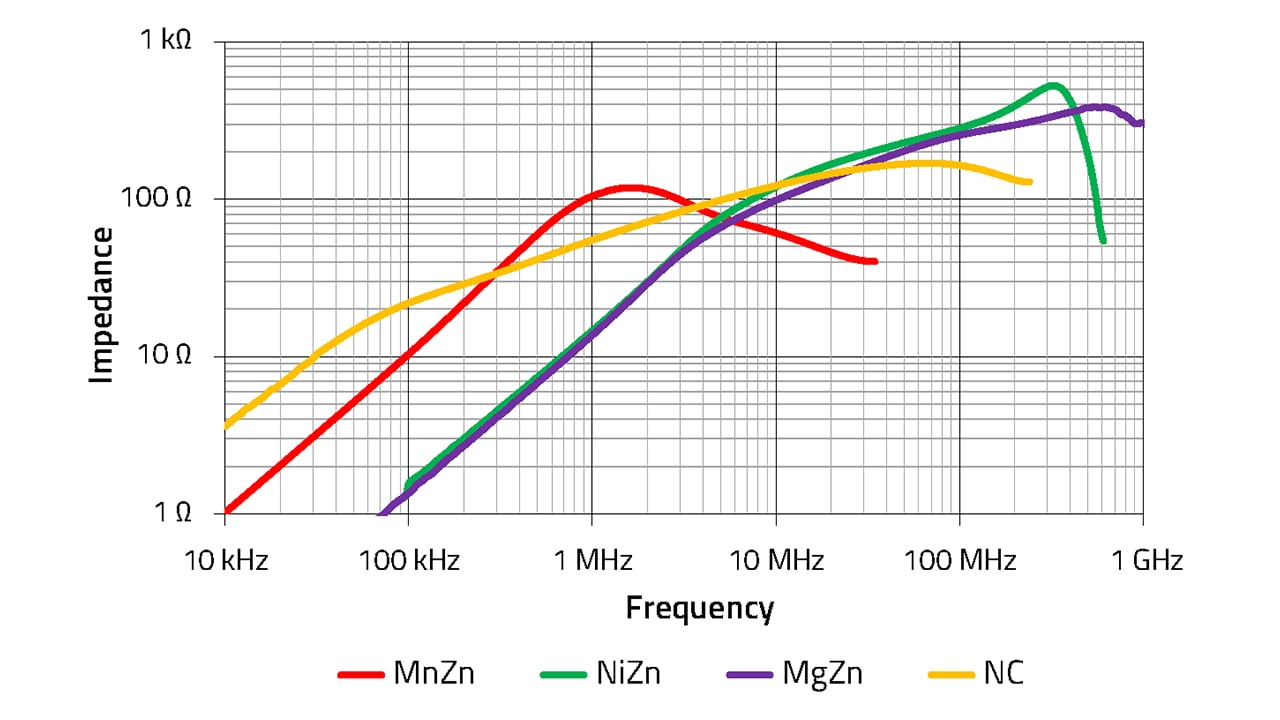

WE-AEFA Axial EMI Suppression Ferrite

Characteristics

- Ferrite core made of NiZn

- Many different types for the best possible interference suppression

- Operating temperature: -55°C up to +150°C

- Automotive approved

Videos

Würth Elektronik Webinar: EMC components for automotive application

Videos

Würth Elektronik Webinar: Automotive requirements to Passive Components – AEC-Q200