Printed circuit boards, often referred to as PCBs or substrates, are thin sheets of insulating material to which solder pads and copper conductors are applied. Metallized holes, known as "vias", connect the conductive layers of a multilayer PCB. The "conductor tracks" connect various soldered-on electronic components to form electrical circuits. The PCB itself usually does not contain any active or passive components. It serves as the basis for the application and electrical connection of the components, i.e. the PCB assembly. Printed circuit boards are used in the aerospace, automotive and communications technology sectors, among others. The high-quality PCBs from Würth Elektronik are characterized by their durability, robustness, reliability and high signal integrity. More than you expect!

Direct access to the required technology

The PCB carries and connects electronic components, thereby converting the electrical circuit diagram and its functions into hardware. As a result, the printed circuit board itself is increasingly becoming a strategically important component and plays a decisive role in the overall system. Virtually every electrical and electronically controlled device contains one or more printed circuit boards.

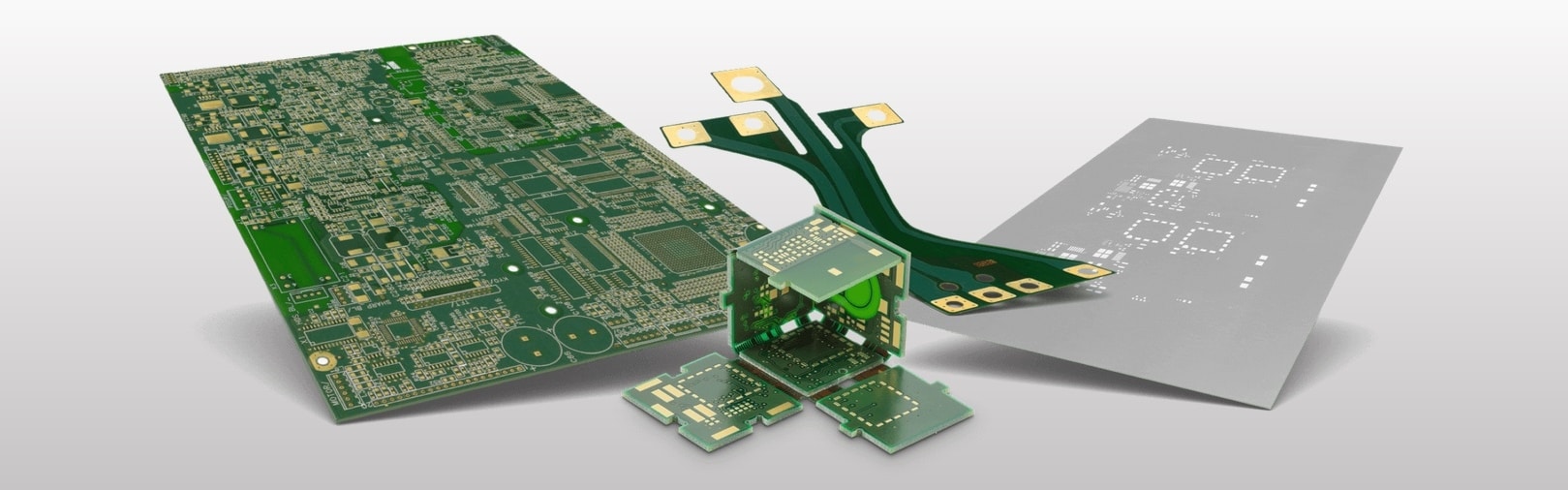

Würth Elektronik Circuit Board Technology has stood for PCB expertise since 1971. Today, as one of Europe's leading PCB supplier, we provide electronics developers with a broad portfolio of PCBs:

Discover our high-quality BASIC PCBs for single-sided, double-sided and multilayer requirements. These PCBs are manufactured from base material in FR4 quality and form the reliable foundation for a wide range of applications.

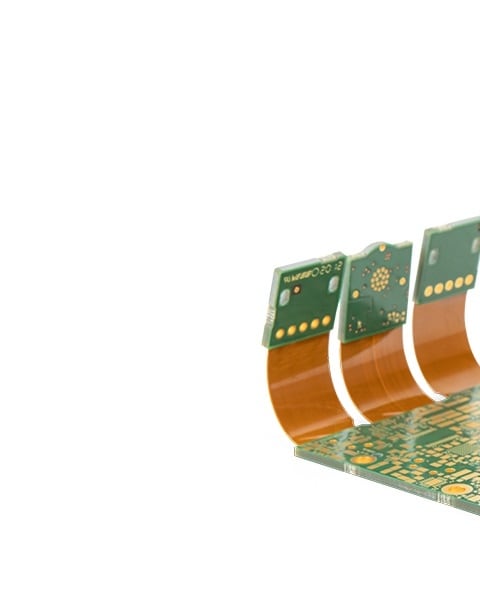

Flexible, rigid-flex and bendable PCBs offer a solution for making optimum use of the limited space in electronic devices. Thanks to their adaptability, they enable the integration of electronic components in housings with complex shapes and limited space.

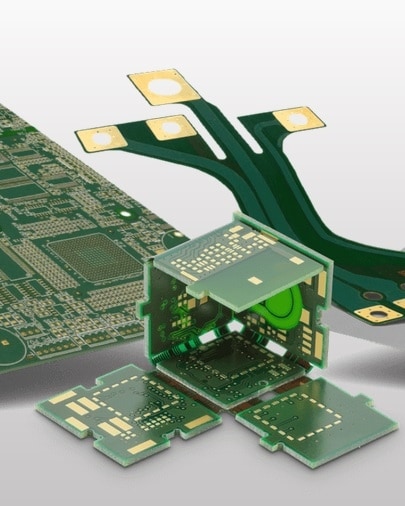

High Density Interconnect (HDI) PCBs and microvia technology are essential components in modern electronics manufacturing processes, where microvias are tiny laser-drilled holes that allow electrical connection between adjacent copper layers in multilayer PCBs.

The future of electronics requires higher reliability and more functions in smaller housings, which is why efficient use of space is crucial. Embedding technology offers a solution by integrating active or passive components directly into the PCB.

As miniaturization progresses and the performance of semiconductors increases, so does the challenge of thermal management on printed circuit boards. To avoid expensive rework, we develop effective measures for heat dissipation at PCB level as early as the design phase.

Printed electronics made from polymer pastes offer an innovative alternative to conventional PCB assembly. With the help of conductive polymers, flat components such as robust contact surfaces, intelligent connection systems and complex resistors can be realized on both the inner and outer layers of the PCB.

We provide a combination of wire bonding services and printed circuit boards, and we also process custom systems.

Find out more and order now

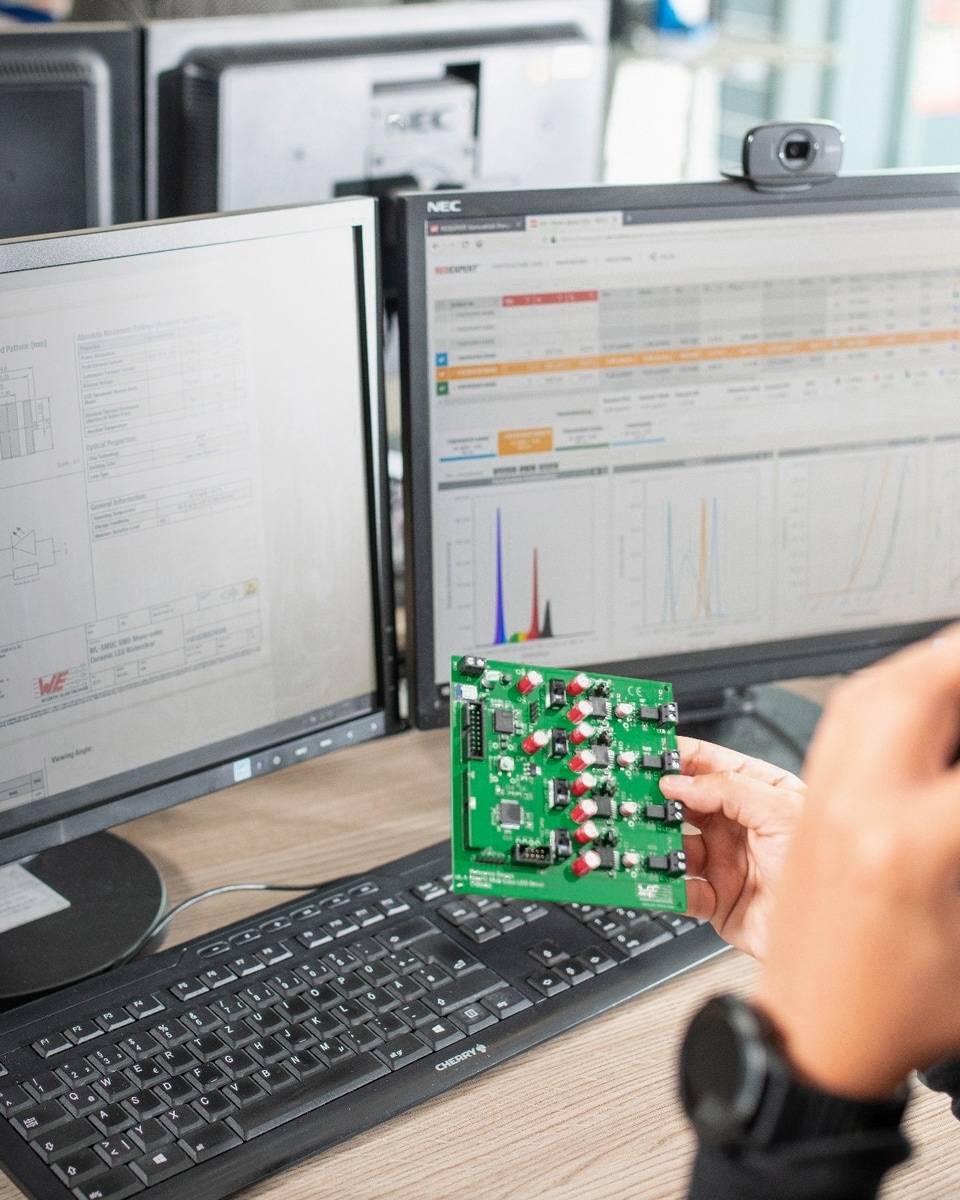

We support our global customers with expert advice via various channels. Thanks to our dense field service network, we are always directly on site with our customers. Our internal sales team is also at your disposal. If required, our technical project management team can be involved in projects at an early stage.

In addition, we offer a wide range of PCB-related services:

WEdirekt Onlineshop

Discover our online shop for printed circuit boards and stencils. Benefit from low-cost PCB production in Germany.

Printed circuit boards (PCBs) are the basis of electronic devices, consisting of insulating plates with conductive tracks applied to them, which connect electronic components to create circuits. They do not contain any components themselves, but are used to assemble and connect them.

The production of printed circuit boards involves the application of a conductive material to an insulating substrate, followed by the photolithographic structuring of the conductive tracks and the drilling of vias. Electronic components are then assembled by soldering to form the final circuit.

PCB technologies include single-sided, double-sided and multi-layer boards for complex circuits. Rigid-flex boards combine rigid and flexible areas for dynamic applications. Semi-flexible boards, on the other hand, offer limited flexibility with specially machined rigid areas for one-off bends during installation.

High-frequency and aluminum boards specialize in heat dissipation and high-speed signals, while high-density interconnect (HDI) technology enables finer traces and smaller components, increasing packing density. In addition, embedding technology allows components to be embedded directly into the PCB, resulting in thinner designs and improved electrical properties.

FR4 is a base material in printed circuit board and PCB production, consisting of a glass fiber-reinforced epoxy resin laminate. It is characterized by particularly high dielectric strength, mechanical strength and thermal resistance, including flame retardancy. This makes it ideal for use in multi-layer PCB constructions for a wide range of electronic applications.

SMD in printed circuit boards describes a technology or method for mounting or assembling electronic components on printed circuit boards, whereby SMD printed circuit boards use surface-mounted device technology. Electronic components are soldered directly to the surface of the board, allowing for a more compact design, higher packing densities and improved electrical performance. Unlike traditional through-hole technology (THT), this method increases production efficiency by focusing on the efficient use of board space.

Printed circuit boards are used in almost all electronic devices and systems. In the automotive industry, they are used in engine management and safety systems, among other things. They can also be found in industrial control systems, where they serve as central components in control and regulation systems in manufacturing and other industrial applications. Printed circuit boards are also indispensable components in the aerospace industry, for example for navigation, communication and monitoring systems. They are also used in medical technology, especially medical devices.

Contact us