Check reliability, detect weak points, assure quality

The printed circuit board is a complex construct made using a wide variety of materials, manufactured by a multitude of processes and it is used for a highly diverse range of applications. Understanding these interrelationships and the possibilities for influencing PCB design are a prerequisite for being able to develop and manufacture reliable PCBs. The process includes a proper specification of the requirements and needs the participation of all involved disciplines.

The manufacturing processes are highly automated and quality-monitored. Quality gates ensure that only defect-free goods are further processed. Final inspection and an electrical test are carried out before delivery.

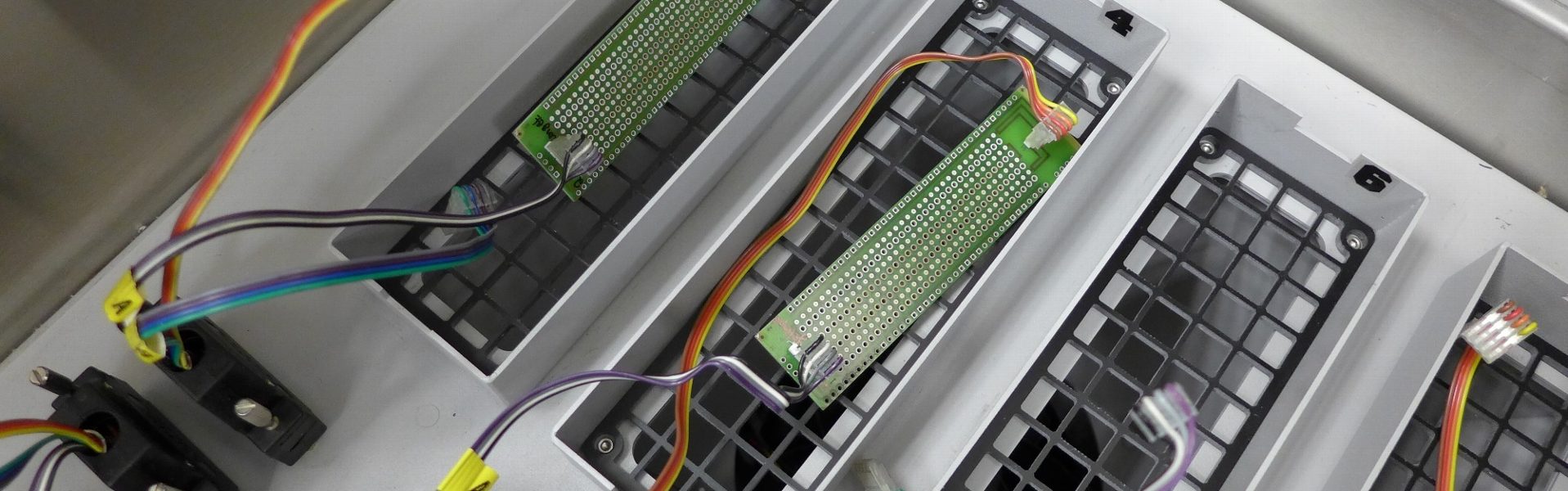

Electrical test of printed circuit boards

Electrical testing of printed circuit boards is performed on parallel testers with part-specific needle bed adapters or by finger testers on 100% of the delivered products. For the creation of the test program the customer data is converted (CAM data test). All printed circuit boards are tested using the adjacency method.

Coil measurements

It is also possible to perform measurements on coils by agreement.

TDR (time domain reflectometry) impedance measurement

It is possible to measure characteristic impedances for specified transmission lines. For this purpose test coupons are generated and used for representative measurement.

Customized tests

For qualification and release tests, we will be happy to carry out additional tests for you:

Interconnect Stress Test (IST)

At Würth Elektronik, the reliability of the PCBs can be assured immediately after its manufacture by means of the Interconnect Stress Test (IST).

Download our brochure "Interconnect Stress Test" for more information.

Test methods

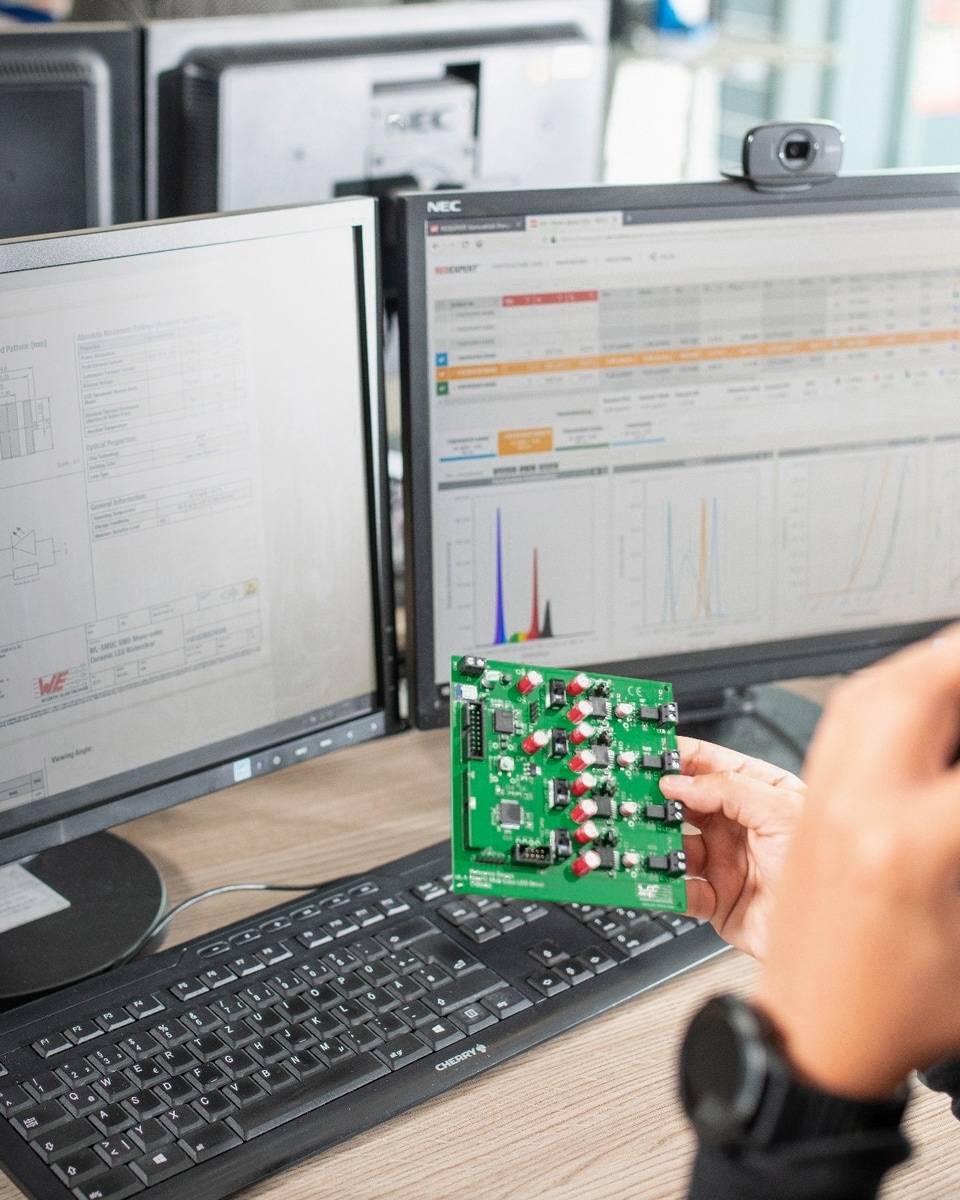

PCBs are often underestimated – both in their importance and in their complexity.

Almost every electronic device contains one or more printed circuit boards. They carry and interconnect components, translate the schematic into hardware, and significantly influence the overall system’s performance.

But a PCB is far more than just a carrier material: it is a highly complex technical product, made from diverse materials, manufactured through numerous mechanical, chemical and thermal processes, and equipped with a wide range of planned mechatronic functions.

In this webinar, we will provide a comprehensive overview of test methods for bare PCBs. You will learn which tests are performed during manufacturing and which electrical, optical, chemical, thermal, and mechanical test and inspection procedures – including microsection analysis – contribute to ensuring PCB quality.

A special focus will be on long-term stability and reliability. We will explain how testing is structured at Würth Elektronik Circuit Board Technology, which industry-specific and application-specific product tests are available, and how the required test scope affects time, cost, and documentation. We also outline the differences between first article testing and series (production) testing.

Gain a practical understanding of how targeted testing and quality assurance can significantly improve the long-term reliability of your assemblies.

What influences does a PCB see during use? Which design decisions often have a serious impact on the robustness of an HDI PCB?

Every printed circuit board is a complex construction made from a wide variety of materials and manufactured using a multitude of processes. They are utilized for a wide variety of applications in different reliability classes. Understanding the interrelationships and knowing the possibilities for influencing PCB design are the necessary foundations for being able to develop and to have reliable PCBs manufactured.

In our webinar we will offer you insights into:

Contact us