LTSpice files

Characteristics

- Long life product series

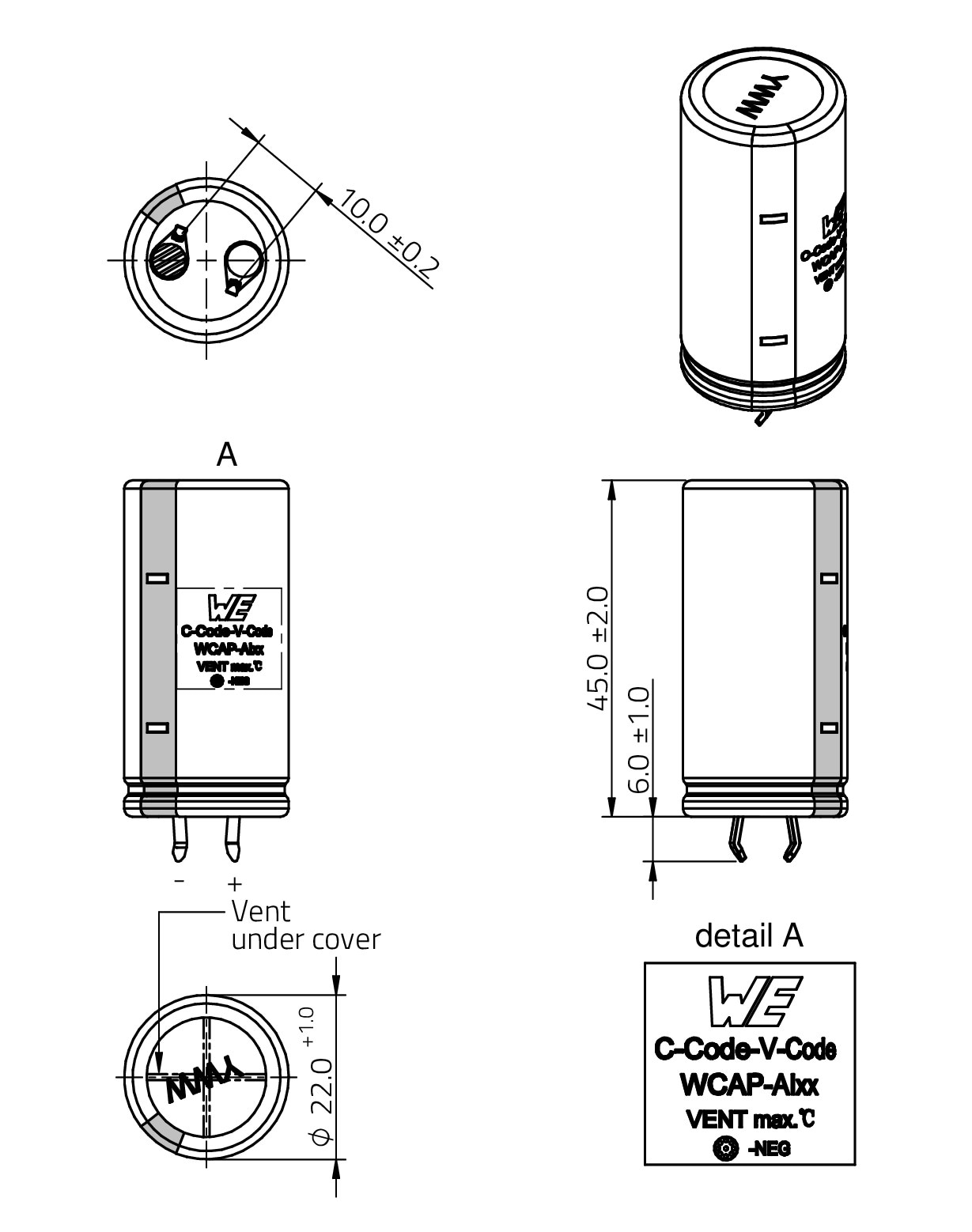

- Mounting style: Snap-In

- Recommended soldering: Wave soldering

Applications

- Long life applications (industry, medical)

- Filtering

- Smoothing

- Energy storage

- e.g. Personal and industrial computer power supply, server power supply, drive circuit, DC/AC inverter

Application Notes

- ANP071 Aluminum Electrolytic vs. Aluminum Polymer Capacitor and how its benefits are used properly

- ANP109 Impedance Spectra of Different Capacitor Technologies

- ANP117 Impact of output capacitor on feedback loop stability of a power supply

- ANP125 Acoustic Effect of Harmonic Distortions caused by Aluminum Electrolytic Capacitors

- SN008 Expected Lifetime of Aluminum Electrolytic and Aluminum Polymer Capacitor

- SN019 Afraid of aging? The effects of time on electrolytic capacitors

Products

All

⌀ 22 mm

⌀ 25 mm

⌀ 30 mm

⌀ 35 mm

| Order Code | Datasheet | Simulation | Downloads | Status | C | VR (V (DC)) | Endurance (h) | IRIPPLE (mA) | ILeak (µA) | DF (%) | Pitch (mm) | Ø D (mm) | L (mm) | Packaging | Samples |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 861221483001 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 68 µF | 450 | 3000 | 710 | 524.8 | 20 | 10 | 22 | 25 | Tray | ||

| 861221483002 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 82 µF | 450 | 3000 | 860 | 576.3 | 20 | 10 | 22 | 25 | Tray | ||

| 861221483003 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 100 µF | 450 | 3000 | 950 | 636.4 | 20 | 10 | 22 | 30 | Tray | ||

| 861221484007 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 100 µF | 450 | 3000 | 970 | 636.4 | 20 | 10 | 25 | 25 | Tray | ||

| 861221483004 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 120 µF | 450 | 3000 | 1140 | 697.2 | 20 | 10 | 22 | 35 | Tray | ||

| 861221484008 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 120 µF | 450 | 3000 | 1170 | 697.2 | 20 | 10 | 25 | 30 | Tray | ||

| 861221485012 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 120 µF | 450 | 3000 | 1210 | 697.2 | 20 | 10 | 30 | 25 | Tray | ||

| 861221483005 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 150 µF | 450 | 3000 | 1380 | 779.5 | 20 | 10 | 22 | 40 | Tray | ||

| 861221484009 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 150 µF | 450 | 3000 | 1310 | 779.5 | 20 | 10 | 25 | 30 | Tray | ||

| 861221485013 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 150 µF | 450 | 3000 | 1340 | 779.5 | 20 | 10 | 30 | 25 | Tray | ||

| 861221483006 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 180 µF | 450 | 3000 | 1560 | 853.9 | 20 | 10 | 22 | 45 | Tray | ||

| 861221484010 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 180 µF | 450 | 3000 | 1510 | 853.9 | 20 | 10 | 25 | 35 | Tray | ||

| 861221485014 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 180 µF | 450 | 3000 | 1450 | 853.9 | 20 | 10 | 30 | 30 | Tray | ||

| 861221484011 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 220 µF | 450 | 3000 | 2020 | 944 | 20 | 10 | 25 | 40 | Tray | ||

| 861221485015 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 220 µF | 450 | 3000 | 1910 | 944 | 20 | 10 | 30 | 30 | Tray | ||

| 861221486019 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 220 µF | 450 | 3000 | 1920 | 944 | 20 | 10 | 35 | 25 | Tray | ||

| 861221385012 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 220 µF | 400 | 3000 | 1660 | 890 | 20 | 10 | 30 | 30 | Tray | ||

| 861221485016 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 270 µF | 450 | 3000 | 2290 | 1045.8 | 20 | 10 | 30 | 35 | Tray | ||

| 861221486020 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 270 µF | 450 | 3000 | 2410 | 1045.8 | 20 | 10 | 35 | 30 | Tray | ||

| 861221485017 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 330 µF | 450 | 3000 | 2650 | 1156.1 | 20 | 10 | 30 | 40 | Tray | ||

| 861221486021 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 330 µF | 450 | 3000 | 2630 | 1156.1 | 20 | 10 | 35 | 35 | Tray | ||

| 861221485018 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 390 µF | 450 | 3000 | 3030 | 1256.8 | 20 | 10 | 30 | 45 | Tray | ||

| 861221486022 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 390 µF | 450 | 3000 | 3150 | 1256.8 | 20 | 10 | 35 | 40 | Tray | ||

| 861221486023 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 470 µF | 450 | 3000 | 3310 | 1379.7 | 20 | 10 | 35 | 45 | Tray | ||

| 861221084006 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 470 µF | 200 | 3000 | 1990 | 919.8 | 15 | 10 | 25 | 25 | Tray | ||

| 861221386021 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 470 µF | 400 | 3000 | 2710 | 1300.8 | 20 | 10 | 35 | 35 | Tray | ||

| 861221486024 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 560 µF | 450 | 3000 | 3580 | 1506 | 20 | 10 | 35 | 50 | Tray | ||

| 861221084017 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 1000 µF | 200 | 3000 | 3280 | 1341.7 | 15 | 10 | 25 | 40 | Tray | ||

| 861220784007 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 3300 µF | 63 | 3000 | 2740 | 1367.9 | 20 | 10 | 25 | 30 | Tray | ||

| 861220785014 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 4700 µF | 63 | 3000 | 3700 | 1632.5 | 30 | 10 | 30 | 30 | Tray | ||

| 861220786020 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 6800 µF | 63 | 3000 | 4950 | 1963.6 | 30 | 10 | 35 | 30 | Tray |

| Order Code | Datasheet | Simulation |

|---|---|---|

| 861221483001 | SPEC | |

| 861221483002 | SPEC | |

| 861221483003 | SPEC | |

| 861221484007 | SPEC | |

| 861221483004 | SPEC | |

| 861221484008 | SPEC | |

| 861221485012 | SPEC | |

| 861221483005 | SPEC | |

| 861221484009 | SPEC | |

| 861221485013 | SPEC | |

| 861221483006 | SPEC | |

| 861221484010 | SPEC | |

| 861221485014 | SPEC | |

| 861221484011 | SPEC | |

| 861221485015 | SPEC | |

| 861221486019 | SPEC | |

| 861221385012 | SPEC | |

| 861221485016 | SPEC | |

| 861221486020 | SPEC | |

| 861221485017 | SPEC | |

| 861221486021 | SPEC | |

| 861221485018 | SPEC | |

| 861221486022 | SPEC | |

| 861221486023 | SPEC | |

| 861221084006 | SPEC | |

| 861221386021 | SPEC | |

| 861221486024 | SPEC | |

| 861221084017 | SPEC | |

| 861220784007 | SPEC | |

| 861220785014 | SPEC | |

| 861220786020 | SPEC |

| Samples |

|---|

| Order Code | Datasheet | Simulation | Downloads | Status | C | VR (V (DC)) | Endurance (h) | IRIPPLE (mA) | ILeak (µA) | DF (%) | Pitch (mm) | Ø D (mm) | L (mm) | Packaging | Samples |

|---|

Videos

#askLorandt explains: DC/DC Converter Voltage Ripple vs. ESR of Different Capacitor Technologies

Videos

How to choose the right capacitor type for a circuit?! || Film vs. Ceramic vs. Electrolytic

Videos

Webinar: Introduction to the capacitor technologies and how to use them