STMicroelectronics VIPERGAN50 | Demoboard EVLVIPGAN50FL

EVLVIPGAN50FL: 15 V/50 W isolated flyback with VIPERGAN50

Overview

| Topology | Flyback Converter |

| Input voltage | 90-265 V |

| Output 1 | 15 V / 3.33 A |

| IC revision | 2.0 |

Description

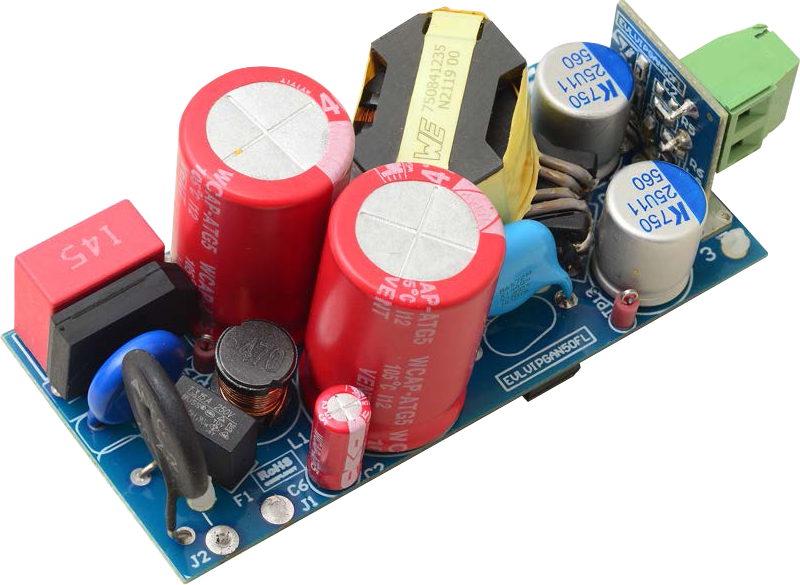

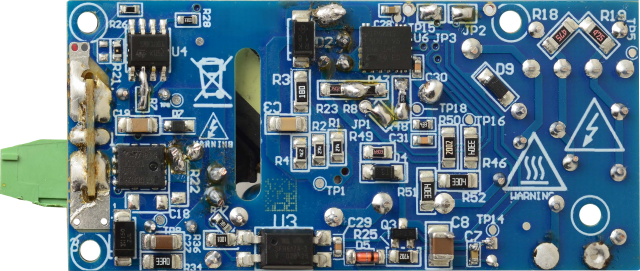

The EVLVIPGAN50FL evaluation board implements a 15 V-50 W SSR isolated flyback converter developed for general purpose application, operating from 90 to 265 VAC.The reference design is built around the VIPERGAN50, a new advanced offline high-voltage converter by STMicroelectronics, having the following features:Enhanced system reliability is ensured by the built-in soft-start function and by the following set of protections:The EVLVIPGAN50FL is composed of a main board and a daughterboard, whose schematics are shown in Figure 1 and Figure 2 respectively.The main board contains, on the primary side, a diode bridge for double wave rectification, an input pi filter for EMI, a flyback transformer, the VIPERGAN50 and all the related components needed for polarization and features setting; on the secondary side, the output capacitors and the output rectifier, realized by a Power MOSFET driven by a synchronous rectifier for efficiency optimization.

Features

- Universal input mains range: 90 – 265 VAC

- Frequency: 50-60 Hz

- Output voltage: 15 V

- Output current: 3.35 A

- Stand-by mains consumption: < 85 mW at 230 VAC

- Average efficiency: > 90%

- Tight line and load regulation over the entire input and output range

- Meets IEC55022 Class B conducted EMI even with reduced EMI filter, thanks to the frequency jittering feature

- RoHS compliant

Typical applications

- Fast battery chargers

- Auxiliary power supply for appliances, industrial, consumers, lighting

More information

Products

| Order Code | Datasheet | Simulation | Downloads | Status | Product series | C | Tol. C | VR (V (DC)) | Size | Operating Temperature | DF (%) | RISO | L (mm) | W (mm) | H (mm) | Fl (mm) | Ceramic Type | Packaging | Application | Safety Class | dV/dt (V/µs) | DF @ 1 kHz (%) | Pitch (mm) | Qmin. | Q (%) | L (µH) | IR (A) | ISAT,10% (A) | RDC max. (mΩ) | fres (MHz) | Version | Endurance (h) | IRIPPLE (mA) | ILeak (µA) | Ø D (mm) | Samples | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 885382206001 | SPEC | 7 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-CSST Soft Termination | 220 pF | ±10% | 50 | 0603 | -55 °C up to +125 °C | 2.5 | 10 GΩ | 1.6 | 0.8 | 0.8 | 0.4 | X7R Class II | 7" Tape & Reel | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | ||

| 885342208017 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-CSMH Mid and High Voltage | 470 pF | ±10% | 1000 | 1206 | -55 °C up to +125 °C | 2.5 | 10 GΩ | 3.2 | 1.6 | 1.25 | 0.6 | X7R Class II | 7" Tape & Reel | – | – | – | – | – | – | 600 | – | – | – | – | – | – | – | – | – | – | ||

| 885012206083 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-CSGP MLCCs 50 V(DC) | 1 nF | ±10% | 50 | 0603 | -55 °C up to +125 °C | 2.5 | 10 GΩ | 1.6 | 0.8 | 0.8 | 0.4 | X7R Class II | 7" Tape & Reel | – | – | – | – | – | 600 | – | – | – | – | – | – | – | – | – | – | – | |||

| 885012206088 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-CSGP MLCCs 50 V(DC) | 6.8 nF | ±10% | 50 | 0603 | -55 °C up to +125 °C | 2.5 | 10 GΩ | 1.6 | 0.8 | 0.8 | 0.4 | X7R Class II | 7" Tape & Reel | – | – | – | – | – | 600 | – | – | – | – | – | – | – | – | – | – | – | |||

| 890334023023CS | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-FTXX Film Capacitors | 100 nF | ±10% | 310 | Pitch 10 mm | -40 °C up to +105 °C | – | 30 GΩ | 13 | 7 | 13 | – | – | Carton | Across the mains | X2 | 300 | 0.1 | 10 | – | – | – | – | – | – | – | – | – | – | – | – | ||

| 885012206095 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-CSGP MLCCs 50 V(DC) | 100 nF | ±10% | 50 | 0603 | -55 °C up to +125 °C | 3 | 5 GΩ | 1.6 | 0.8 | 0.8 | 0.4 | X7R Class II | 7" Tape & Reel | – | – | – | – | – | 600 | – | – | – | – | – | – | – | – | – | – | – | |||

| 885012206076 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-CSGP MLCCs 25 V(DC) | 1 µF | ±10% | 25 | 0603 | -55 °C up to +125 °C | 10 | 0.5 GΩ | 1.6 | 0.8 | 0.8 | 0.4 | X7R Class II | 7" Tape & Reel | – | – | – | – | – | 600 | – | – | – | – | – | – | – | – | – | – | – | |||

| 885012208068 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-CSGP MLCCs 25 V(DC) | 4.7 µF | ±10% | 25 | 1206 | -55 °C up to +125 °C | 7 | 0.1 GΩ | 3.2 | 1.6 | 1.6 | 0.6 | X7R Class II | 7" Tape & Reel | – | – | – | – | – | 600 | – | – | – | – | – | – | – | – | – | – | – | |||

| 885012208069 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-CSGP MLCCs 25 V(DC) | 10 µF | ±10% | 25 | 1206 | -55 °C up to +125 °C | 10 | 0.01 GΩ | 3.2 | 1.6 | 1.6 | 0.5 | X7R Class II | 7" Tape & Reel | – | – | – | – | – | 600 | – | – | – | – | – | – | – | – | – | – | – | |||

| 860020672011 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-ATG5 Aluminum Electrolytic Capacitors | 22 µF | ±20% | 50 | – | – | 10 | – | 11 | – | – | – | – | Ammopack | – | – | – | – | 2 | – | – | – | – | – | – | – | – | 2000 | 60 | 11 | 5 | ||

| 860021380015 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | WCAP-ATG5 Aluminum Electrolytic Capacitors | 47 µF | ±20% | 400 | – | – | 15 | – | 25 | – | – | – | – | Ammopack | – | – | – | – | 7.5 | – | – | – | – | – | – | – | – | 2000 | 300 | 564 | 16 | ||

| 7447720470 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | WE-TI Radial Leaded Wire Wound Inductor | – | – | 120 | 8095 | -40 °C up to +125 °C | – | – | 7.8 | 7.8 | 9.5 | – | – | – | – | – | – | – | – | – | – | 47 | 2 | 2.3 | 120 | 9.1 | Standard | – | – | – | – | ||

| 750841235 | SPEC | – | – | Active i| Production is active. Expected lifetime: >10 years. | Offline Transformer | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Samples |

|---|

| Order Code | Datasheet | Simulation | Downloads | Status | Product series | C | Tol. C | VR (V (DC)) | Size | Operating Temperature | DF (%) | RISO | L (mm) | W (mm) | H (mm) | Fl (mm) | Ceramic Type | Packaging | Application | Safety Class | dV/dt (V/µs) | DF @ 1 kHz (%) | Pitch (mm) | Qmin. | Q (%) | L (µH) | IR (A) | ISAT,10% (A) | RDC max. (mΩ) | fres (MHz) | Version | Endurance (h) | IRIPPLE (mA) | ILeak (µA) | Ø D (mm) | Samples |

|---|