|

885382206001

|

220 pF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

220

pF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0603

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

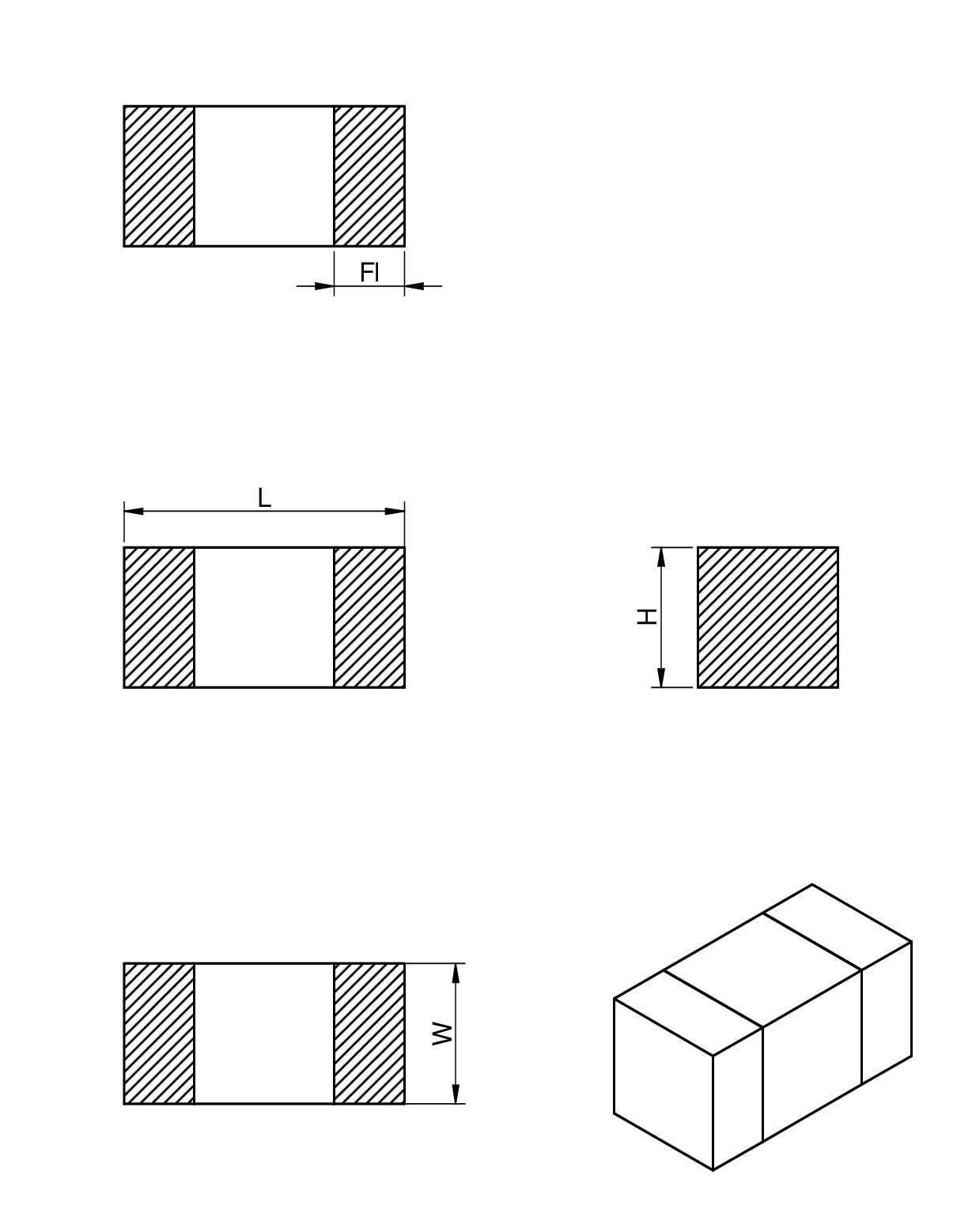

Length

1.6 mm

|

Width

0.8 mm

|

Height

0.8 mm

|

Pad Dimension

0.4 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382207010

|

270 pF, ±10%, 500 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

270

pF

|

Capacitance

±10%

|

Rated Voltage

500 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208008

|

270 pF, ±10%, 500 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

270

pF

|

Capacitance

±10%

|

Rated Voltage

500 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.25 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208013

|

470 pF, ±10%, 2000 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

470

pF

|

Capacitance

±10%

|

Rated Voltage

2000 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.25 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208014

|

680 pF, ±10%, 2000 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

680

pF

|

Capacitance

±10%

|

Rated Voltage

2000 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.25 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382206005

|

1 nF, ±10%, 200 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

1

nF

|

Capacitance

±10%

|

Rated Voltage

200 V (DC)

|

Size

0603

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

1.6 mm

|

Width

0.8 mm

|

Height

0.8 mm

|

Pad Dimension

0.4 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382207004

|

1 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

1

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382207005

|

2.2 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

2.2

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208012

|

4.7 nF, ±10%, 1000 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

4.7

nF

|

Capacitance

±10%

|

Rated Voltage

1000 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.25 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382206002

|

10 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

10

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0603

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

1.6 mm

|

Width

0.8 mm

|

Height

0.8 mm

|

Pad Dimension

0.4 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382207006

|

10 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

10

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382207009

|

10 nF, ±10%, 100 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

10

nF

|

Capacitance

±10%

|

Rated Voltage

100 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208002

|

10 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

10

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.25 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208009

|

10 nF, ±10%, 500 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

10

nF

|

Capacitance

±10%

|

Rated Voltage

500 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.25 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382206003

|

22 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

22

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0603

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

10

GΩ

|

Length

1.6 mm

|

Width

0.8 mm

|

Height

0.8 mm

|

Pad Dimension

0.4 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208010

|

22 nF, ±10%, 500 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

22

nF

|

Capacitance

±10%

|

Rated Voltage

500 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

4.5

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.6 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208011

|

33 nF, ±10%, 500 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

33

nF

|

Capacitance

±10%

|

Rated Voltage

500 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

3

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.6 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382209001

|

33 nF, ±10%, 500 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

33

nF

|

Capacitance

±10%

|

Rated Voltage

500 V (DC)

|

Size

1210

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

3

GΩ

|

Length

3.2 mm

|

Width

2.5 mm

|

Height

1.6 mm

|

Pad Dimension

0.75 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382206004

|

100 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

100

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0603

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

3 %

|

Insulation Resistance

5

GΩ

|

Length

1.6 mm

|

Width

0.8 mm

|

Height

0.8 mm

|

Pad Dimension

0.4 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382207007

|

100 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

100

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

5

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208003

|

100 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

100

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

5

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.25 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208006

|

100 nF, ±10%, 100 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

100

nF

|

Capacitance

±10%

|

Rated Voltage

100 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

1

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.25 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208007

|

100 nF, ±10%, 250 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

100

nF

|

Capacitance

±10%

|

Rated Voltage

250 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

1

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.6 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382211002

|

100 nF, ±10%, 1000 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

100

nF

|

Capacitance

±10%

|

Rated Voltage

1000 V (DC)

|

Size

1812

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

1

GΩ

|

Length

4.5 mm

|

Width

3.2 mm

|

Height

2.5 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

Design Kit

–

|

|

|

885382207008

|

220 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

220

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

3 %

|

Insulation Resistance

2.3

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382207002

|

330 nF, ±10%, 25 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

330

nF

|

Capacitance

±10%

|

Rated Voltage

25 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

3.5 %

|

Insulation Resistance

1.5

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208004

|

470 nF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

470

nF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

3 %

|

Insulation Resistance

1

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.6 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382211003

|

470 nF, ±10%, 500 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

470

nF

|

Capacitance

±10%

|

Rated Voltage

500 V (DC)

|

Size

1812

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

2.5 %

|

Insulation Resistance

0.2

GΩ

|

Length

4.5 mm

|

Width

3.2 mm

|

Height

2.5 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

Design Kit

–

|

|

|

885382207001

|

1 µF, ±10%, 16 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

1

µF

|

Capacitance

±10%

|

Rated Voltage

16 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

5 %

|

Insulation Resistance

0.5

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382207003

|

1 µF, ±10%, 25 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

1

µF

|

Capacitance

±10%

|

Rated Voltage

25 V (DC)

|

Size

0805

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

5 %

|

Insulation Resistance

0.5

GΩ

|

Length

2 mm

|

Width

1.25 mm

|

Height

1.25 mm

|

Pad Dimension

0.5 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208005

|

1 µF, ±10%, 50 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

1

µF

|

Capacitance

±10%

|

Rated Voltage

50 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

3 %

|

Insulation Resistance

0.5

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.6 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208001

|

2.2 µF, ±10%, 25 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

2.2

µF

|

Capacitance

±10%

|

Rated Voltage

25 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

3.5 %

|

Insulation Resistance

0.2

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.6 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382209002

|

2.2 µF, ±10%, 100 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

2.2

µF

|

Capacitance

±10%

|

Rated Voltage

100 V (DC)

|

Size

1210

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

5 %

|

Insulation Resistance

0.05

GΩ

|

Length

3.2 mm

|

Width

2.5 mm

|

Height

2.5 mm

|

Pad Dimension

0.75 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

|

|

|

885382208016

|

2.2 µF, ±10%, 100 V (DC)

|

|

|

Status

Active

i

| Production is active. Expected lifetime: >10 years.

|

Capacitance

2.2

µF

|

Capacitance

±10%

|

Rated Voltage

100 V (DC)

|

Size

1206

|

Operating Temperature

-55 °C up to +125 °C

|

Dissipation Factor

5 %

|

Insulation Resistance

0.05

GΩ

|

Length

3.2 mm

|

Width

1.6 mm

|

Height

1.6 mm

|

Pad Dimension

0.6 mm

|

Ceramic Type

X7R Class II

|

Packaging

7" Tape & Reel

|

Design Kit

–

|

|