Thermal Management

You‘ve Got Better Options Than That

Enhance reliability with our thermal interface material portfolio

Thermal Management

You‘ve Got Better Options Than That

Enhance reliability with our thermal interface material portfolio

In today's fast-paced world of electronic design, managing heat is more critical than ever. As devices become more powerful and compact, the challenge of effective thermal management grows exponentially. Overheating can lead to reduced performance, system failures, and shortened lifespans of your valuable electronics. That's where our thermal interface materials come in to fill a gap or spread heat over a surface

Our solutions are designed to tackle these challenges head-on, ensuring your electronic components stay cool and perform at their best. With our thermal management products, you can boost the reliability and longevity of your designs, preventing costly downtime and enhancing overall efficiency. Don't let heat be a barrier to your innovation – trust our thermal interface materials to keep your electronics running smoothly.

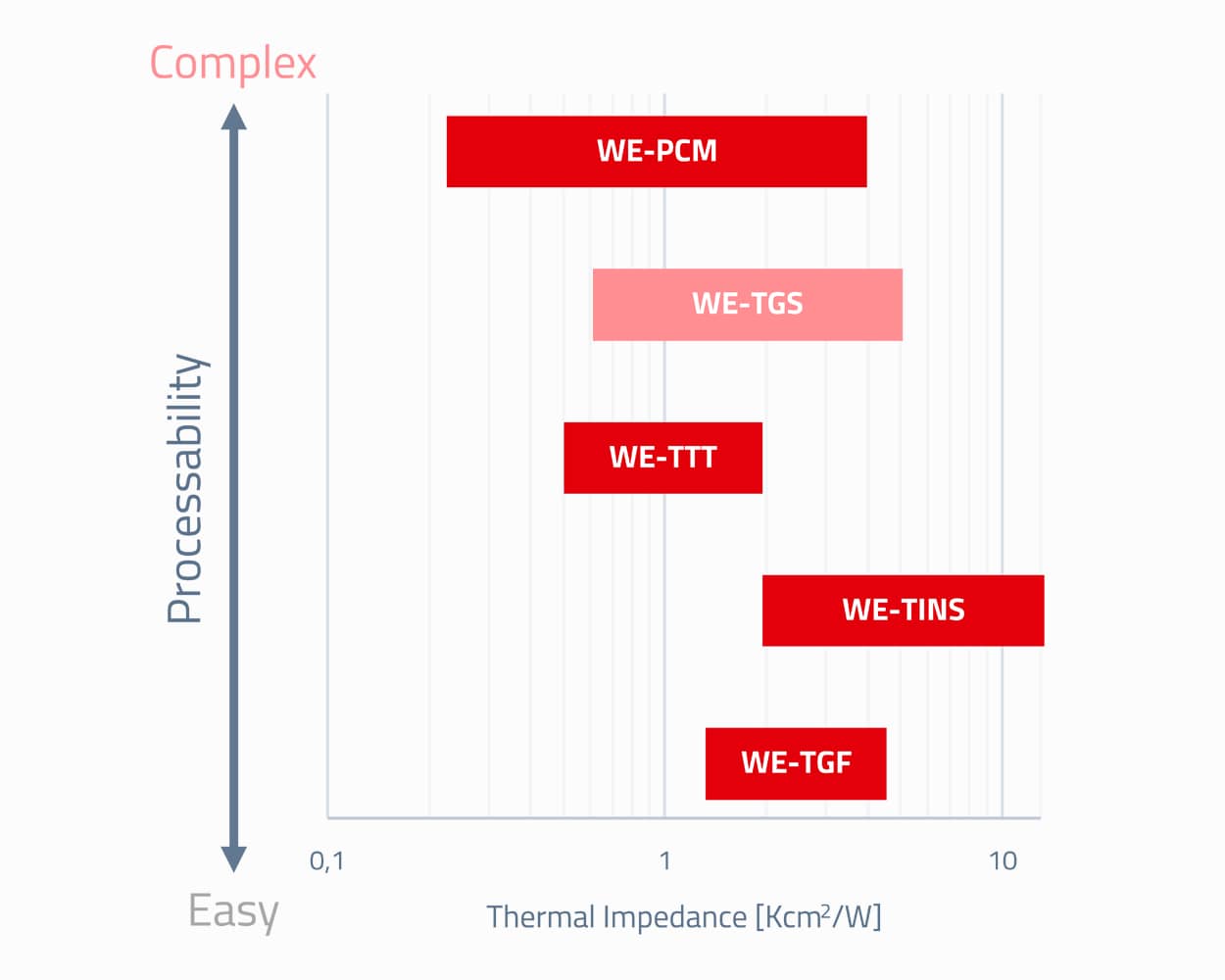

Thermal Interface Material Portfolio

Discover our gap filling and heat spreading solutions

Elastomeric Gap Filler Pad

Versatile gap-filling solution: broad range of

thicknesses and thermal performance

- 0.5 – 18 mm between 1-3 W/mK

- 0.5 – 3 mm between 4-6 W/mK

- Electrically isolating

- Naturally tacky

Thermally Conductive Insulator Pad

Thermal interface for high-pressure situations

- Able to withstand compressing forces up to 68 N/cm2 [100 PSI]

- Adhesive layer optional

- High dielectric strength

- Standard transistor profiles available

Phase Changing Material

Lowest thermal resistance of the portfolio

- Solid at room temperature, liquid in operating temperatures

- Easier-handling alternative to thermal pastes

- More resilient to pump-out effect than thermal pastes

- Polyimide guarantees electrical isolation between contact surfaces

Thermally Conductive Adhesive Tape

Attach a cooling assembly to your hot component without the need of additional mechanical assembly

- 5.7 N/cm Adhesive strength

- Electrically insulating between contact surfaces

Synthetic Graphite Heat Spreader

Enhance the performance of other materials with the

graphite sheet. Larger hot surfaces transfer more energy

- One side adhesive

- Electrical isolation between contact surface of 1kV

Graphite Foam Gasket

Take advantage of the high in-plane thermal conductivity of graphite in a gap-filling setting

- Versatile gap filler: custom profiles for

non-planar contact surfaces

- Electrically isolating

- Adhesive on one side for ease of assembly

Applications

Importance of selecting the right TIM

Selecting the right thermal interface material (TIM) is crucial for optimizing both the performance and cost-efficiency of your electronic designs. Each type of TIM offers unique benefits and is suited to different applications, making it essential to choose the one that best meets your specific needs.

The primary function of a TIM is to enhance heat transfer between components, thereby preventing overheating and ensuring reliable operation. For instance, Silicone Elastomer Pads are excellent for filling larger gaps and providing electrical insulation, while Phase Change Materials offer superior thermal conductivity and stability under thermal cycling, making them ideal for high-performance applications. Thermal Transfer Tapes provide a convenient and effective solution for bonding components with moderate thermal requirements, and Synthetic Graphite Heat Spreaders are perfect for applications needing high thermal conductivity and flexibility. By selecting the appropriate TIM, you can significantly improve the thermal management of your devices, leading to enhanced performance and longevity.

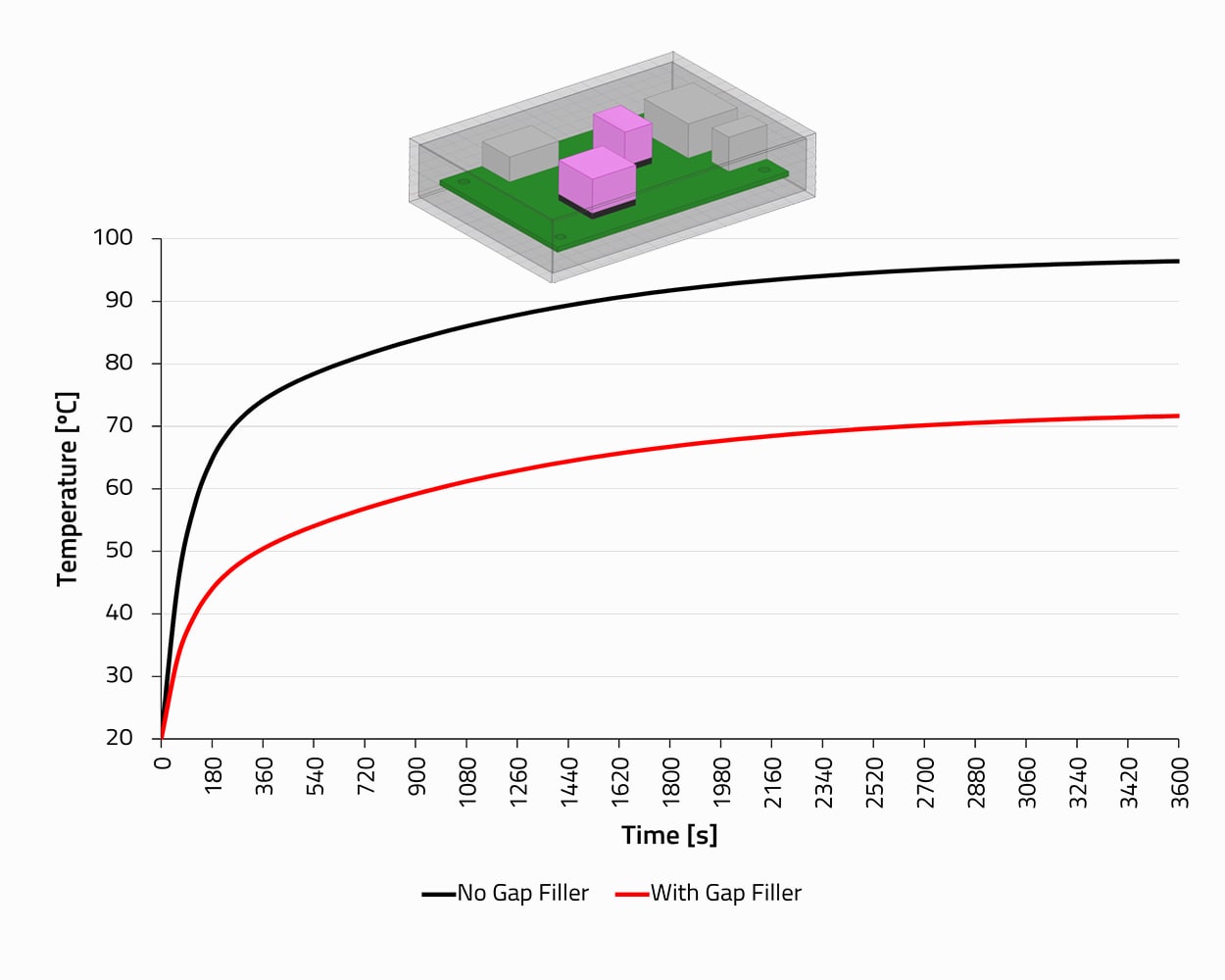

Gap Filling

Gap fillers play a crucial role in maintaining optimal thermal management in electronic devices. These materials are designed to bridge the microscopic gaps between heat sources and heatsinks, ensuring efficient heat transfer. By filling these tiny voids, gap fillers eliminate air pockets that can act as thermal insulators, significantly improving the thermal conductivity between components. This results in more effective cooling, which helps maintain the performance and reliability of your electronics.

For larger gaps, such as those between heat sources and housings, gap fillers provide a flexible and reliable solution. They conform to irregular surfaces and ensuring consistent thermal contact. This adaptability not only enhances heat dissipation but also reduces mechanical stress on components, preventing damage and extending the lifespan of your devices.

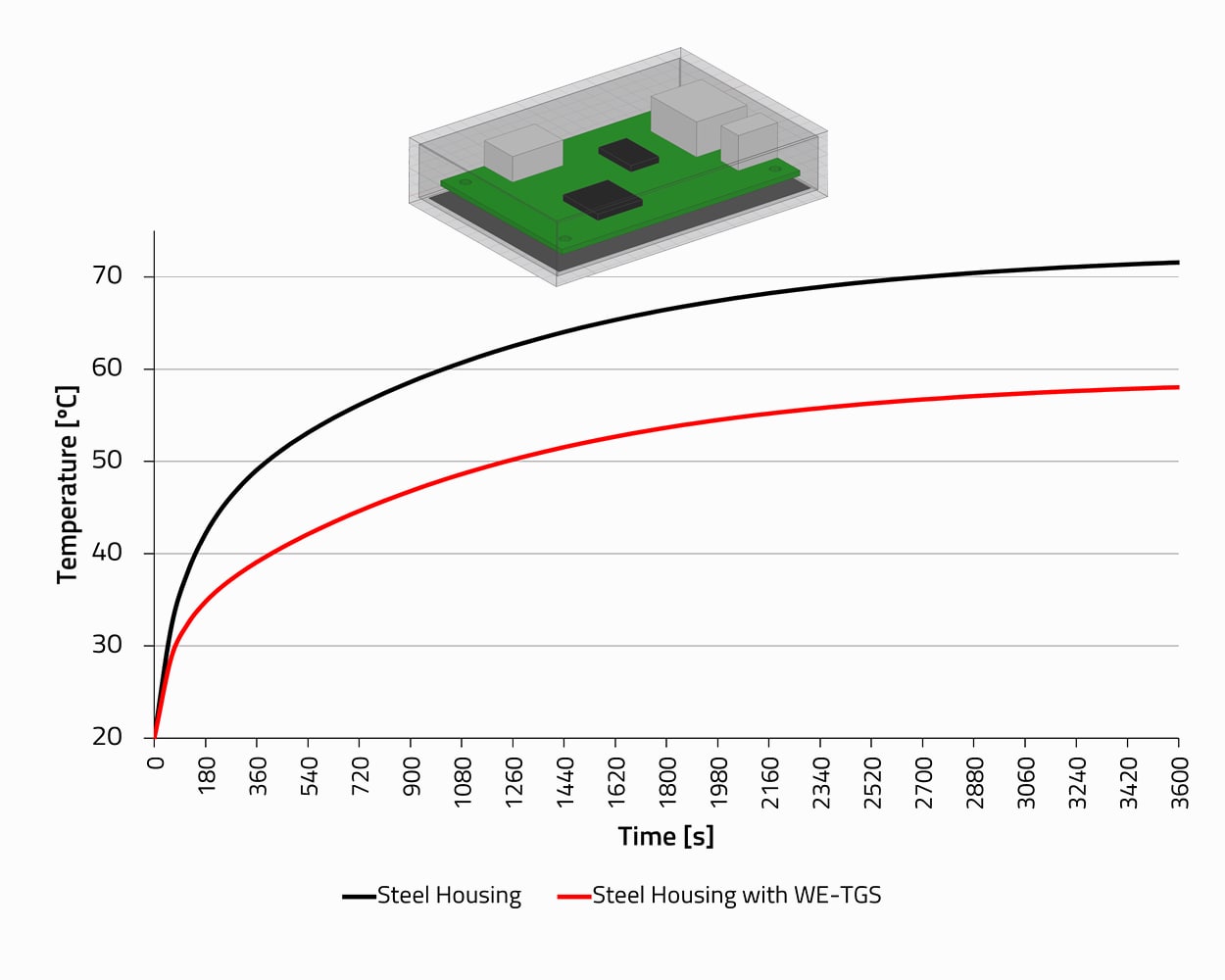

Heat Spreading

Synthetic graphite heat spreaders offer several compelling benefits as a cooling strategy for electronic devices. One of the primary advantages is their exceptional thermal conductivity, which can be significantly higher than that of traditional materials like aluminum or copper. This high thermal conductivity allows synthetic graphite to efficiently dissipate heat away from critical components, ensuring that devices operate within safe temperature ranges. Additionally, it is lightweight and flexible, making it ideal for applications where space and weight are constraints, such as in mobile devices, laptops, and other compact electronics.

Another key benefit of synthetic graphite heat spreaders is their ability to provide uniform heat distribution. This characteristic helps to prevent hot spots, which can lead to localized overheating and potential component failure. By spreading heat evenly across the surface, more energy can be transferred to the ambient, contributing to improved performance and reliability.

More than you expect

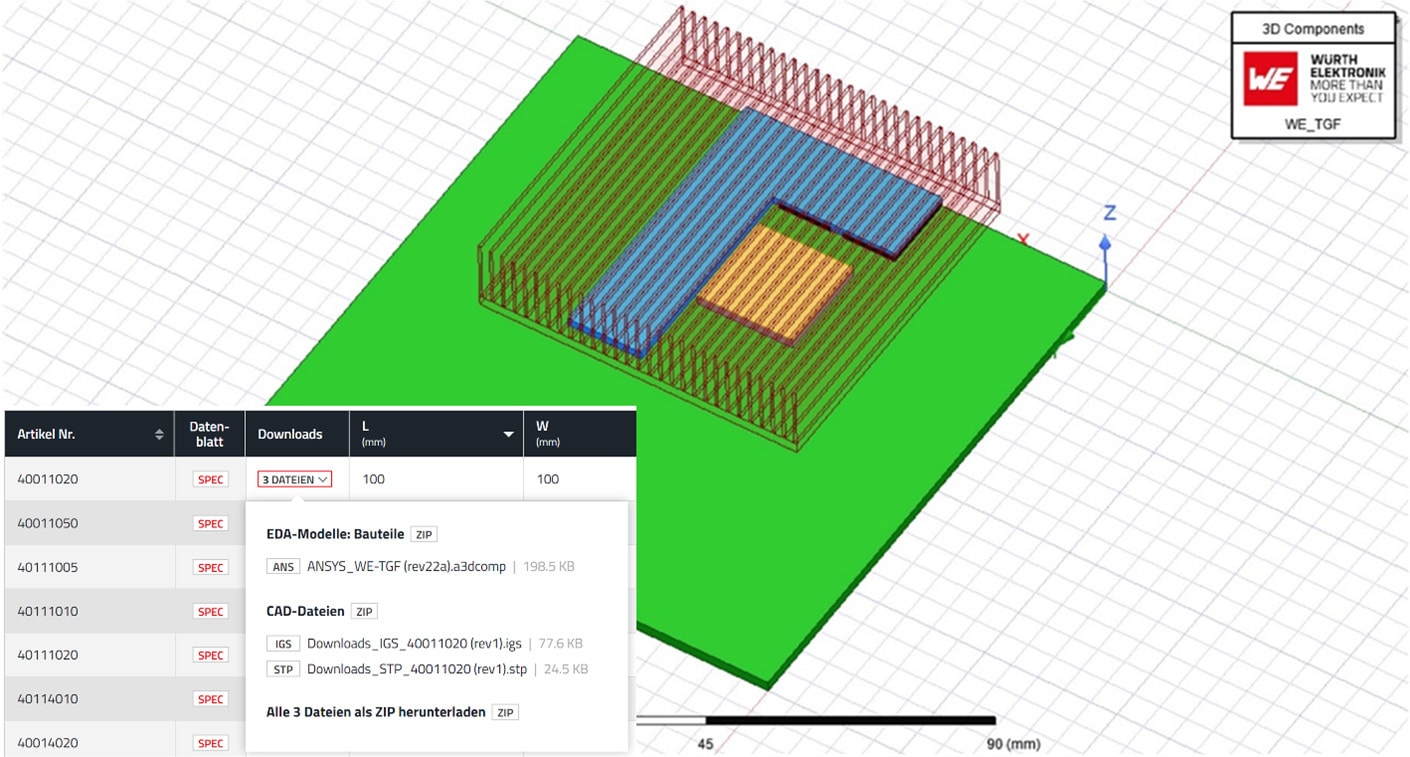

Ansys Models

More than you expect

Design Guidelines

More than you expect

Design Guidelines

These guidelines condense the product and application knowledge that has been developed over years of supporting designers with thermal management issues. You will find:

- Detailed specification and technical information

- Design-in examples: LED, Power, FPGA …

- Measurement set-ups

- Installation and handling recommendations

Do you need assistance?

Do you need assistance?

Whether in Person, via Contact Form, Chat or Telephone. Our Technical Specialists Are at Your Side With Advice and Support for Your Questions and Projects.