Würth Elektronik capacitors

Big portfolio available ex stock

Würth Elektronik capacitors

Big portfolio available ex stock

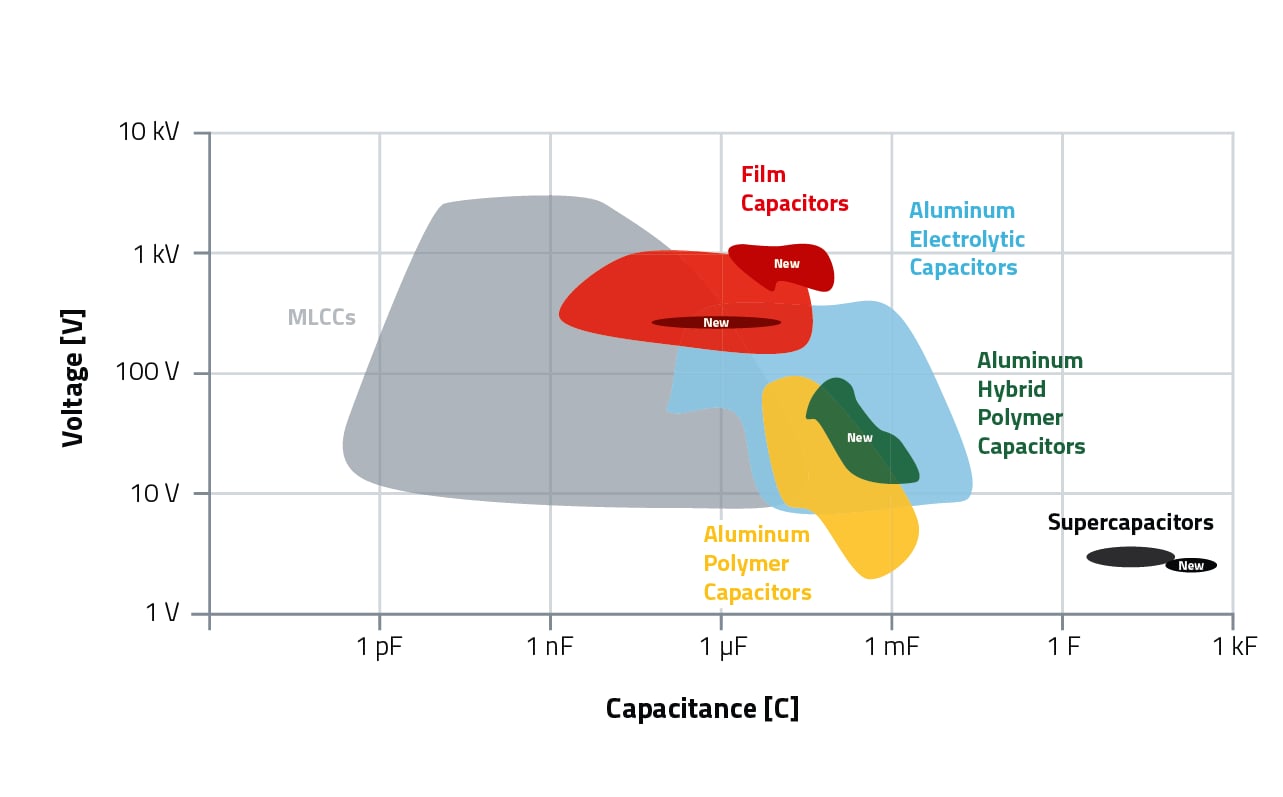

Würth Elektronik has extended its capacitor portfolio. You will find an overview of our current technologies available ex stock in the graph. More details (e.g. series, characteristics, features, applications, etc.) about each product family can be found in the flyer or for example below. In our flyer you will also find information about our services.

Available series

Comparison of aluminum capacitors

Aluminum electrolytic capacitors

- Stable capacitance values at high temperature

- High voltage ratings

- Low leakage current

Aluminum hybrid polymer capacitors

- Low ESR

- High ripple current characteristics

- High stability over the temperature range

- Low leakage current

- High lifetime performance

Aluminum polymer capacitors

- Low ESR

- High ripple current characteristics

- High lifetime performance

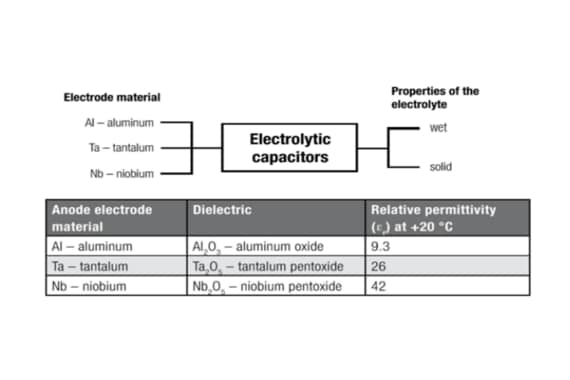

Construction

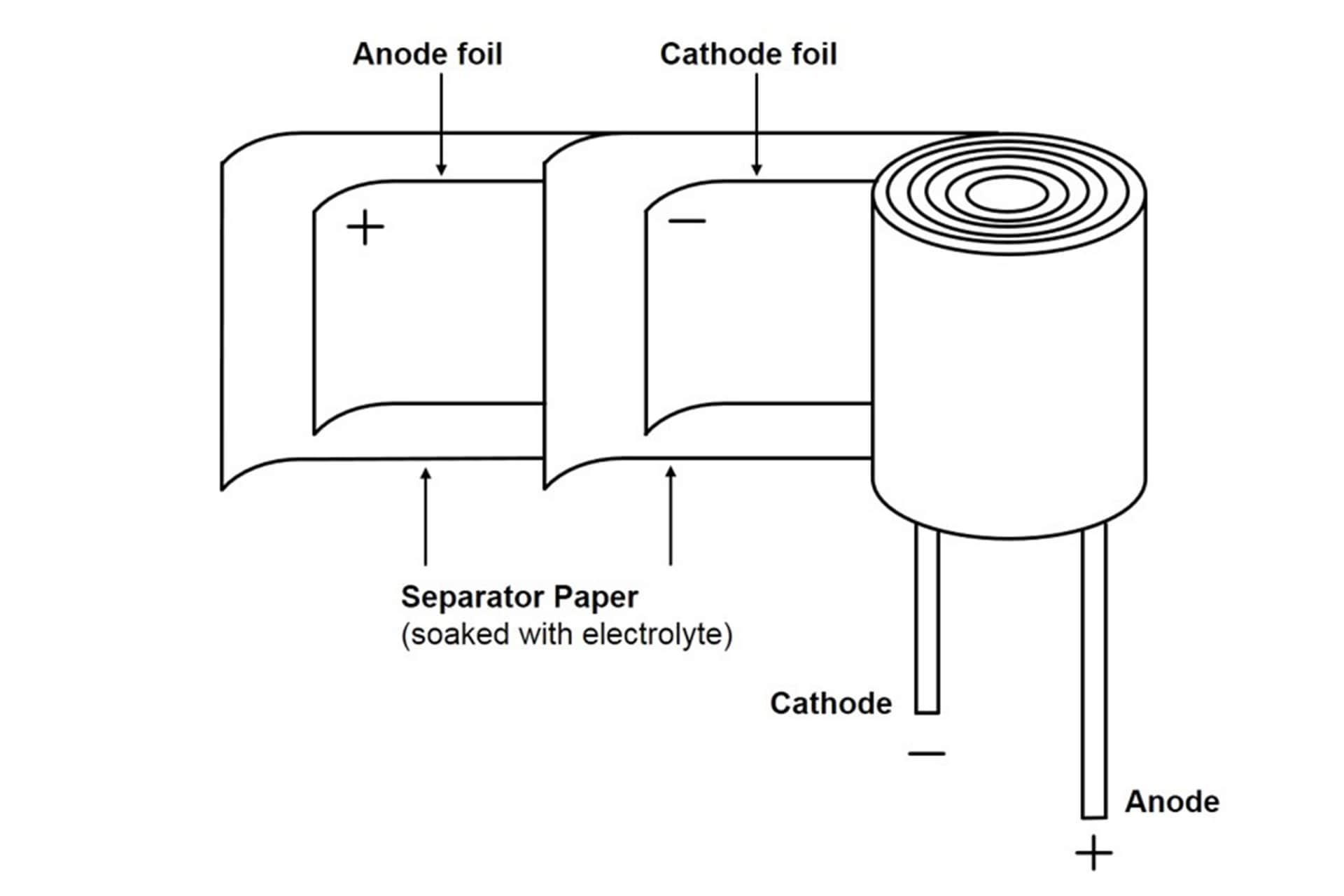

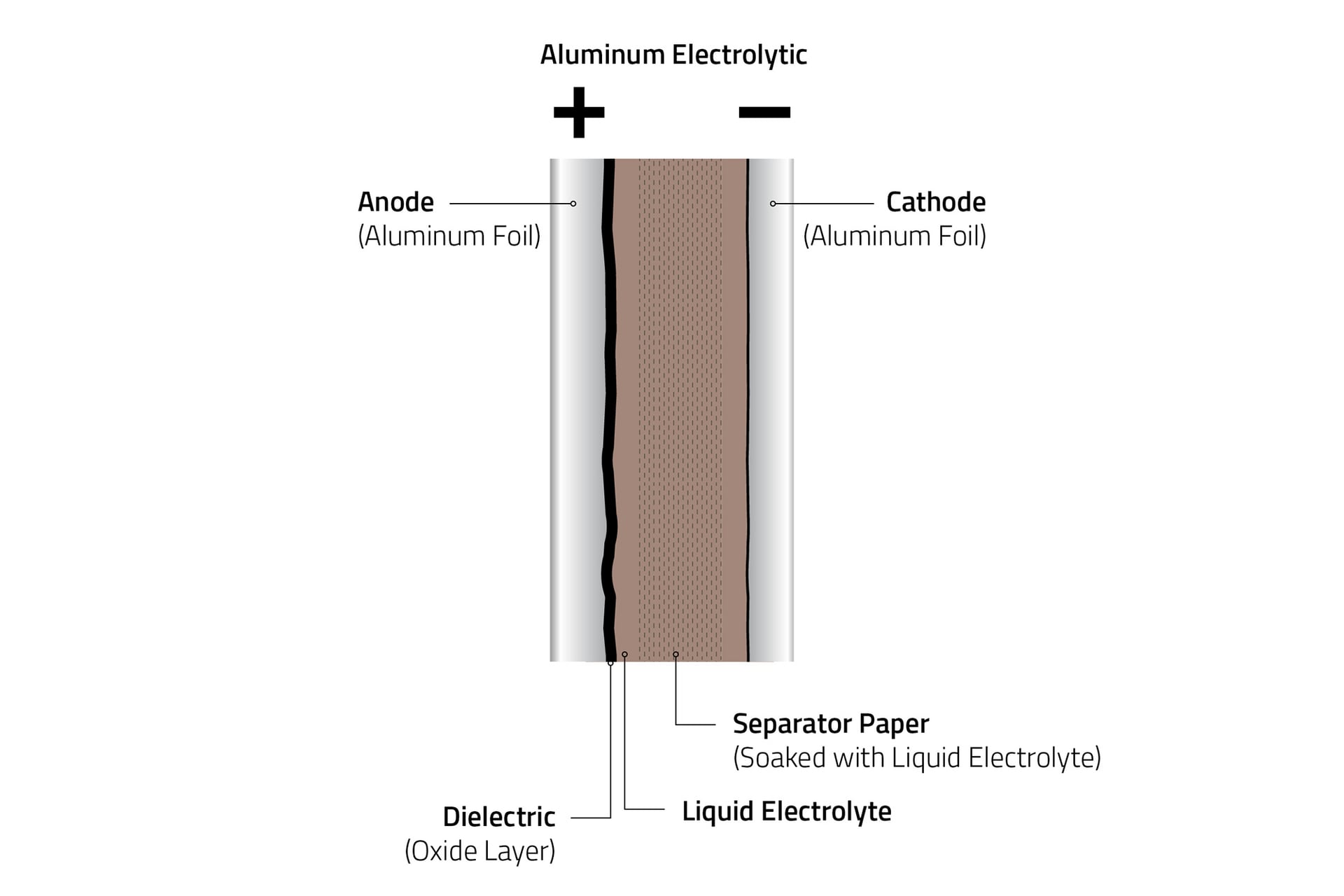

Wound capacitor

Aluminum electrolytic capacitors are wound capacitors. These consist of aluminum foils with a layer of paper in between.

Layer structure

The aluminum foil of the anode is formed by anodic oxidation before winding, so that the dielectric (oxide layer) is strengthened. The wound capacitor is completely soaked in electrolyte. This electrolyte is evenly distributed through the paper layer. In addition, the paper layer ensures a distance between the anode and cathode foil.

Example applications

Measurements

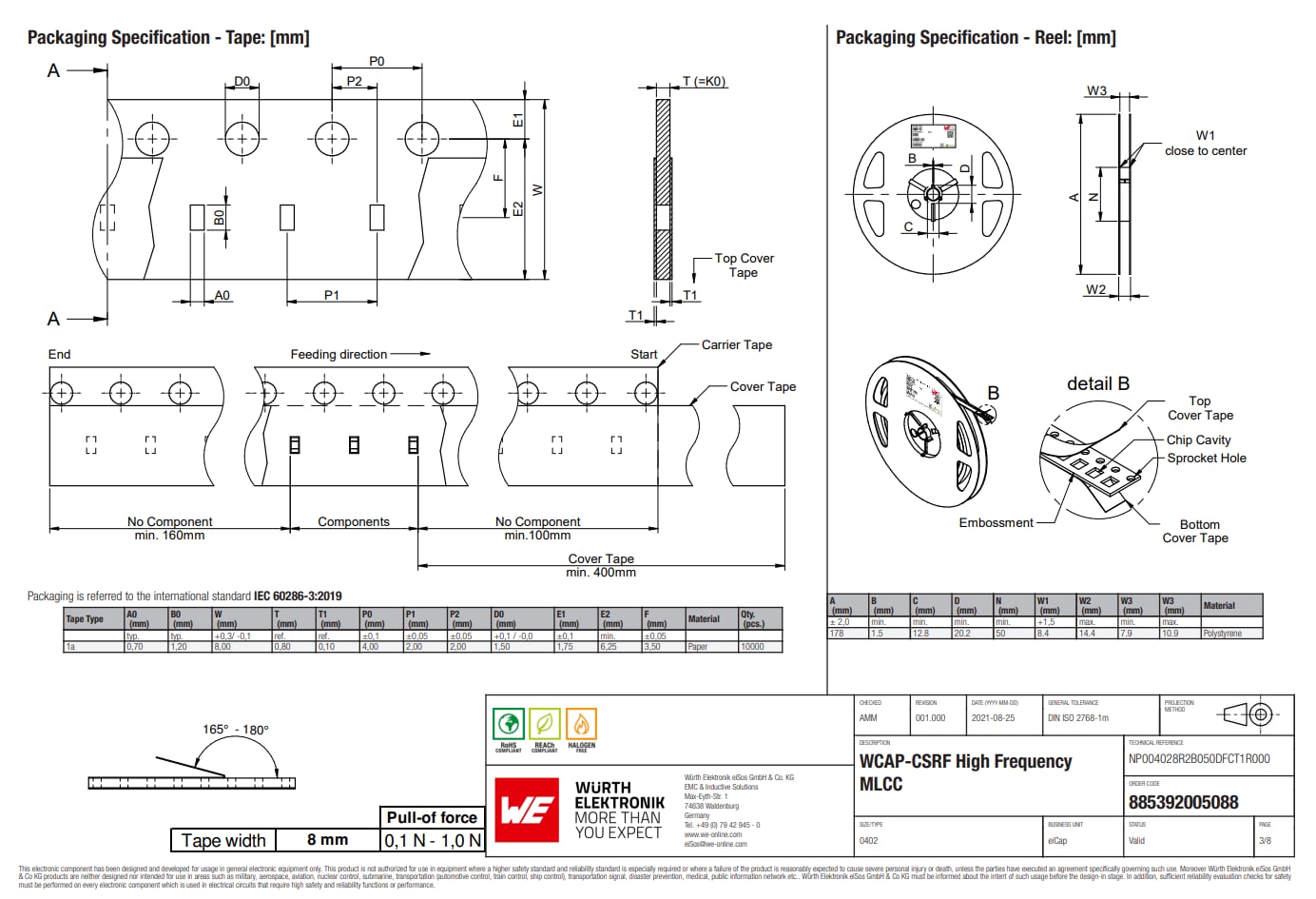

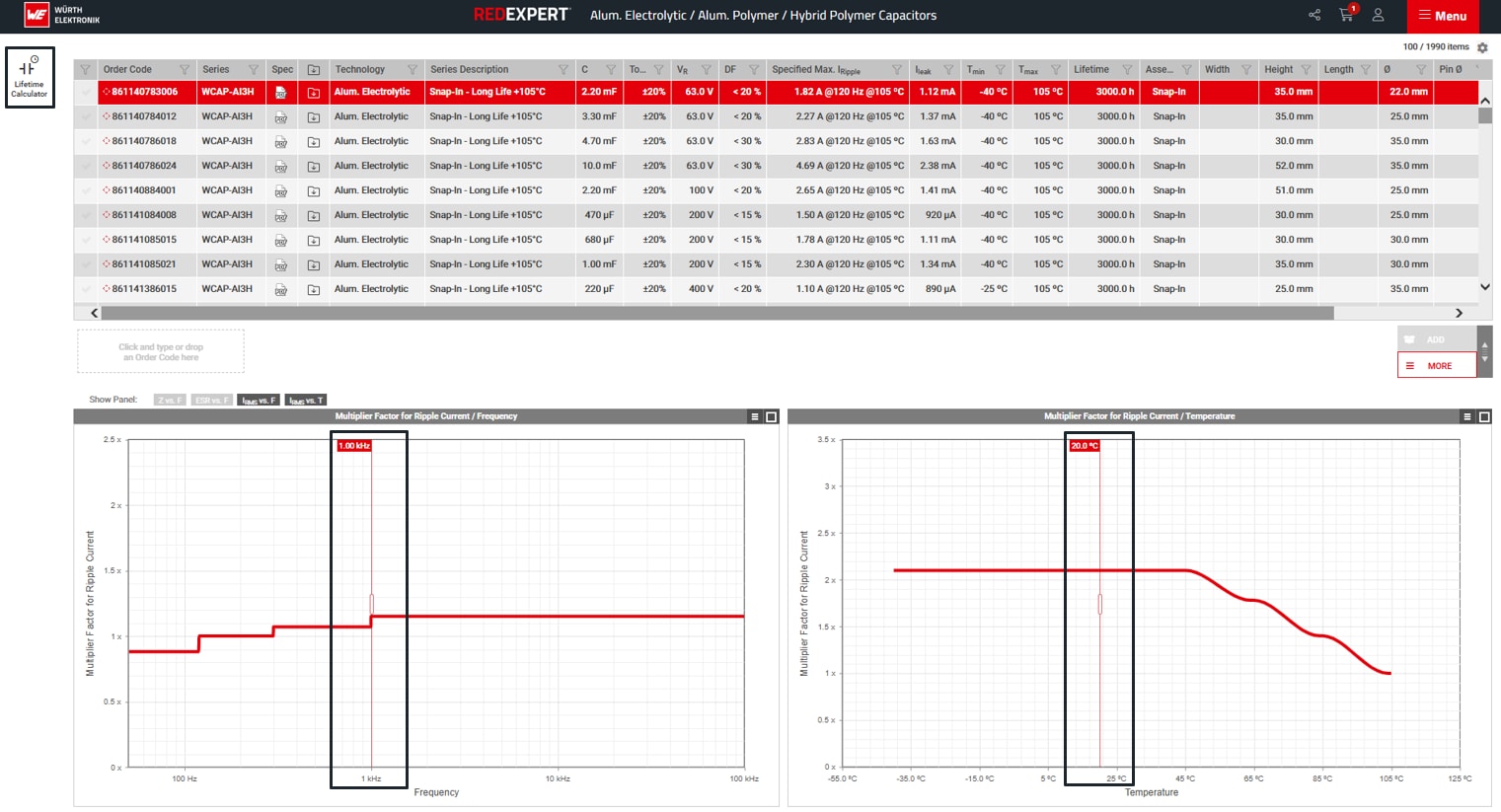

Redexpert

Measurements

Redexpert

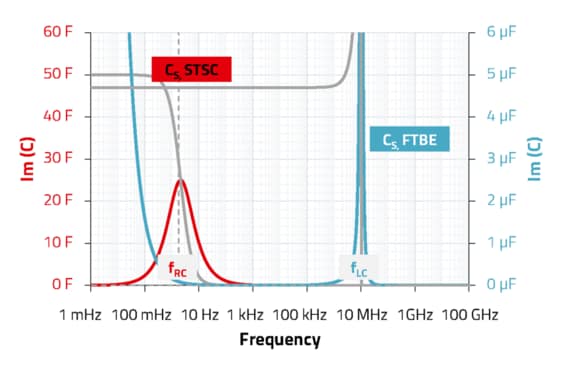

With the help of REDEXPERT you will find the right capacitor based on your technical requirements. The tool supports, for example, with measured values for capacitance, impedance, ESR and dissipation factor (DF). The ability to compare individual components with each other in terms of measured values enables convenient component selection.

Lifetime

Lifetime calculator

With this tool you can calculate your maximum expected lifetime. Depending on the product family, a different formula is used for the calculation. This calculator can be found in the aluminum capacitor module on the REDEXPERT platform.

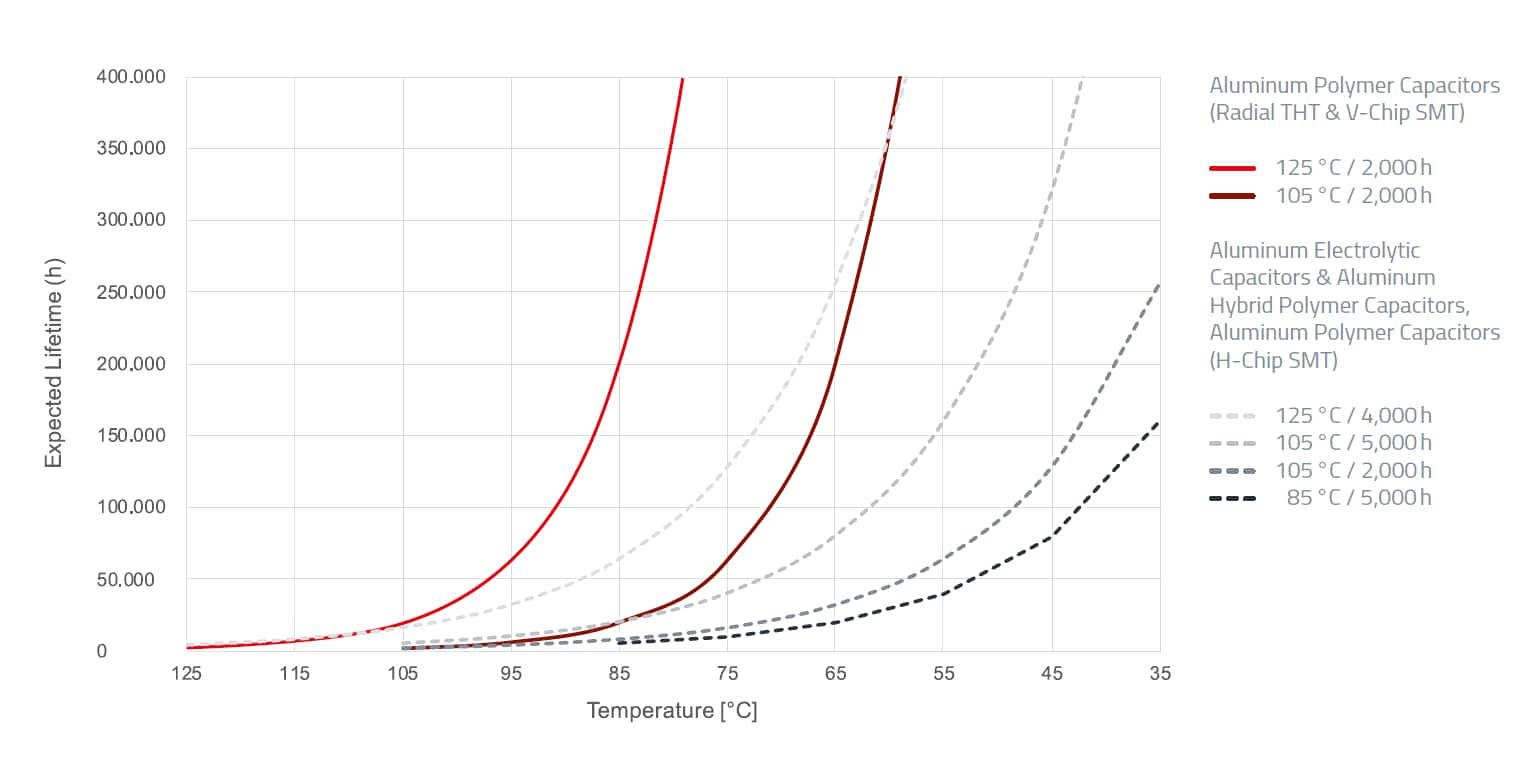

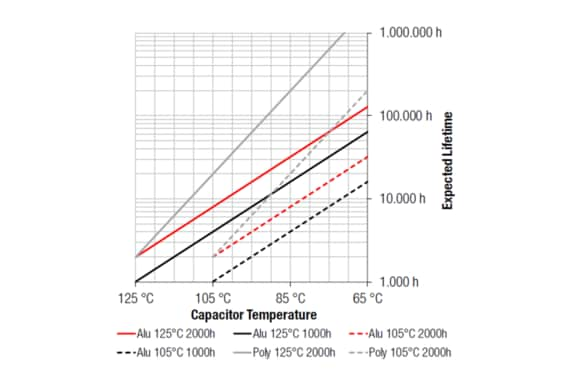

Expected lifetime vs. temperature

In this graph you can find the difference in expected lifetime between our different product families. The curves are based on the different formulas and the endurance of this product. The lifetime table and formula can be found in the information sheet.

Webinar

Introduction to the capacitor technologies and how to use them

Webinar

Introduction to the capacitor technologies and how to use them

Capacitors make up two thirds of all electronic components and there is a huge diversity of technologies which can overwhelm young engineers. All capacitors store electrical energy in the electrical field created in a dielectric material and they are used for very diverse applications like voltage stability and filtering. How that works differs between tiny MLCCs and huge electrolytic cells, from pF ratings up to the hundreds of Farads in supercapacitors. In this presentation, we introduce different capacitor solutions taking into account the advantages and disadvantages and with a focus on the final application.

Application notes and documents

FAQ aluminium capacitors

You can find the certifications in the datasheet, page 2.

In the case of X/Y safety capacitors, certification information can be found in PDF format in the online platform REDEXPERT.

These links are shown at the right end of the table, under the column “Certificates”.

We provide the document with all the values on our homepage.

You can also download the document by searching for “FIT” or “MTBF” in our download center.

This document reveals the FIT (Failures in time) and MTBF (Mean time between failures) values that can be calculated for each series based on the electrical stress (voltage applied in the case of capacitors) and the temperature applied according to calculation models of Telcordia SR-332 Issue 3.

Please refer to the table of contents at the beginning of the document to find the values for capacitors.

- Würth Elektronik part number

- Actual ambient operating temperature which the capacitor is used at (°C)

- Operating ripple current flowing through the capacitor (A, RMS)

- Frequency of the ripple current (Hz)

- Operating voltage which is applied to the capacitor (V(DC))

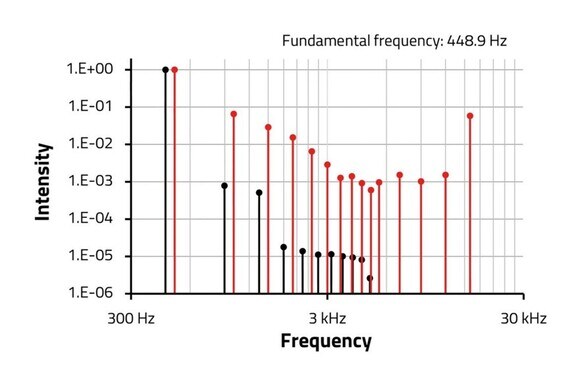

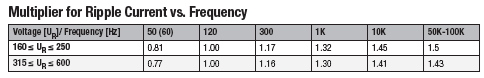

For all capacitors of series WCAP-A***, WCAP-P*** and WCAP-H*** there is a maximum ripple current in the datasheet. This ripple current is defined at a specific frequency and temperature and it is given as a RMS (root mean square) value.

Since the ripple current is defined at a certain frequency, it can be converted into the respective value for certain frequencies using factors. These factors can be found in the data sheet.

Let’s assume that the rated ripple current of this part (400V part) is 1 A @ 120 Hz. The max. ripple current @ max. temperature and 10 kHz is then 1.41 A.Furthermore, the ripple current can also be increased if the temperature is below the maximum component temperature. However, this must always be considered in the context of the expected lifetime.

The lifetime calculation in RedExpert can be used for a simple estimate. For detailed considerations, please use one of the many ways of contacting Würth Elektronik to obtain a specific lifetime estimate for your capacitor selection. This value may be increased or decreased if the operating conditions in the application are different from the datasheet.

You can find the lifetime calculation on REDEXPERT.

The lifetime calculator may be opened with the sand clock button in the left of the Electrolytic/Polymer/Hybrid . The user must be registered and logged, as this functionality is restricted to registered users.

You can set the conditions in the input box and for Frequency and Temperature you may also move the sliders in the graphs in the right.