| Kind Properties | |

|---|---|

| PCB Thickness | 1.6 mm |

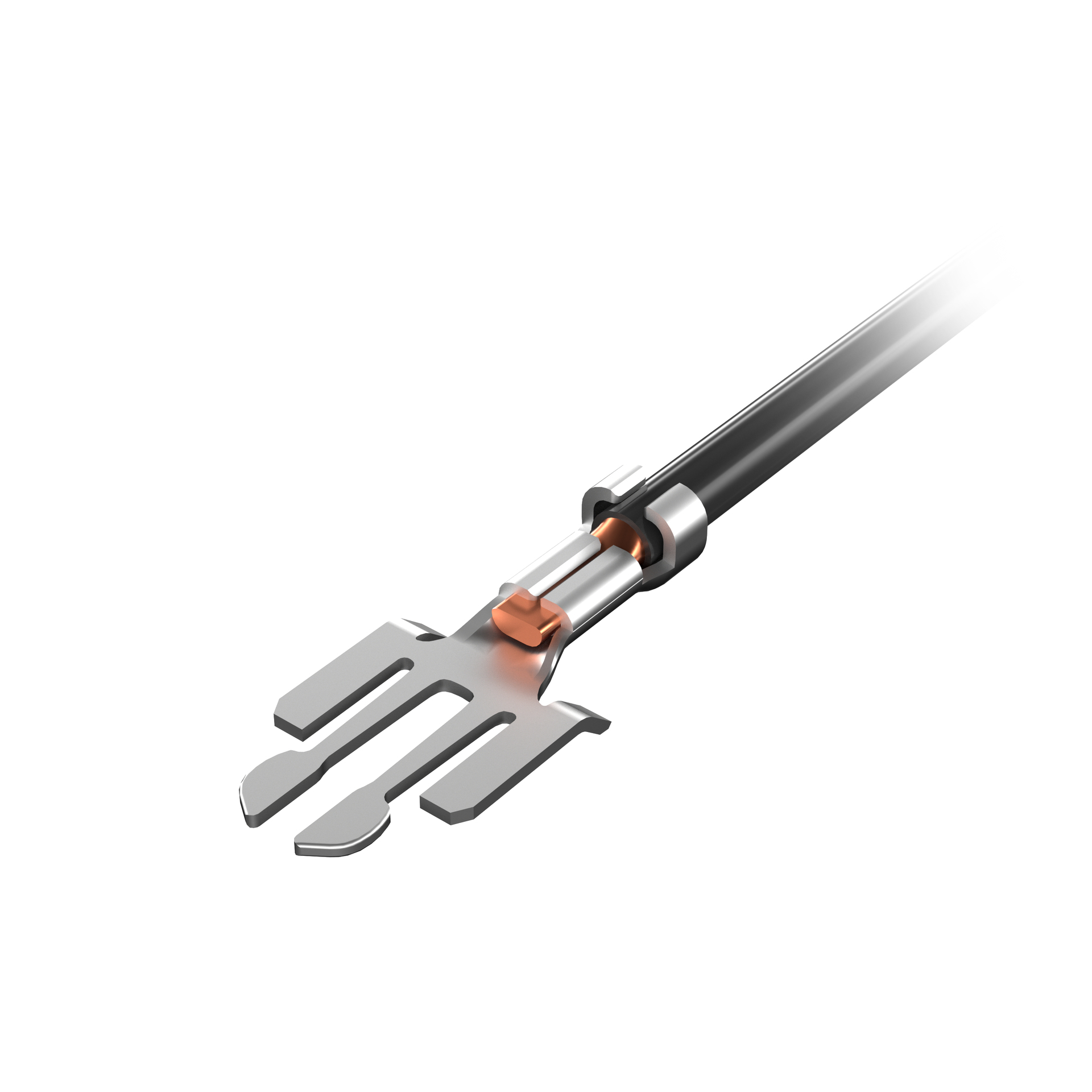

| Wire Section (Metric) | 0.75 to 1.5 (mm²) |

| General Information | |

|---|---|

| Operating Temperature | -25 °C up to +105 °C |

| Mating Cycle | 10 Cycles |

| Material Properties | |

|---|---|

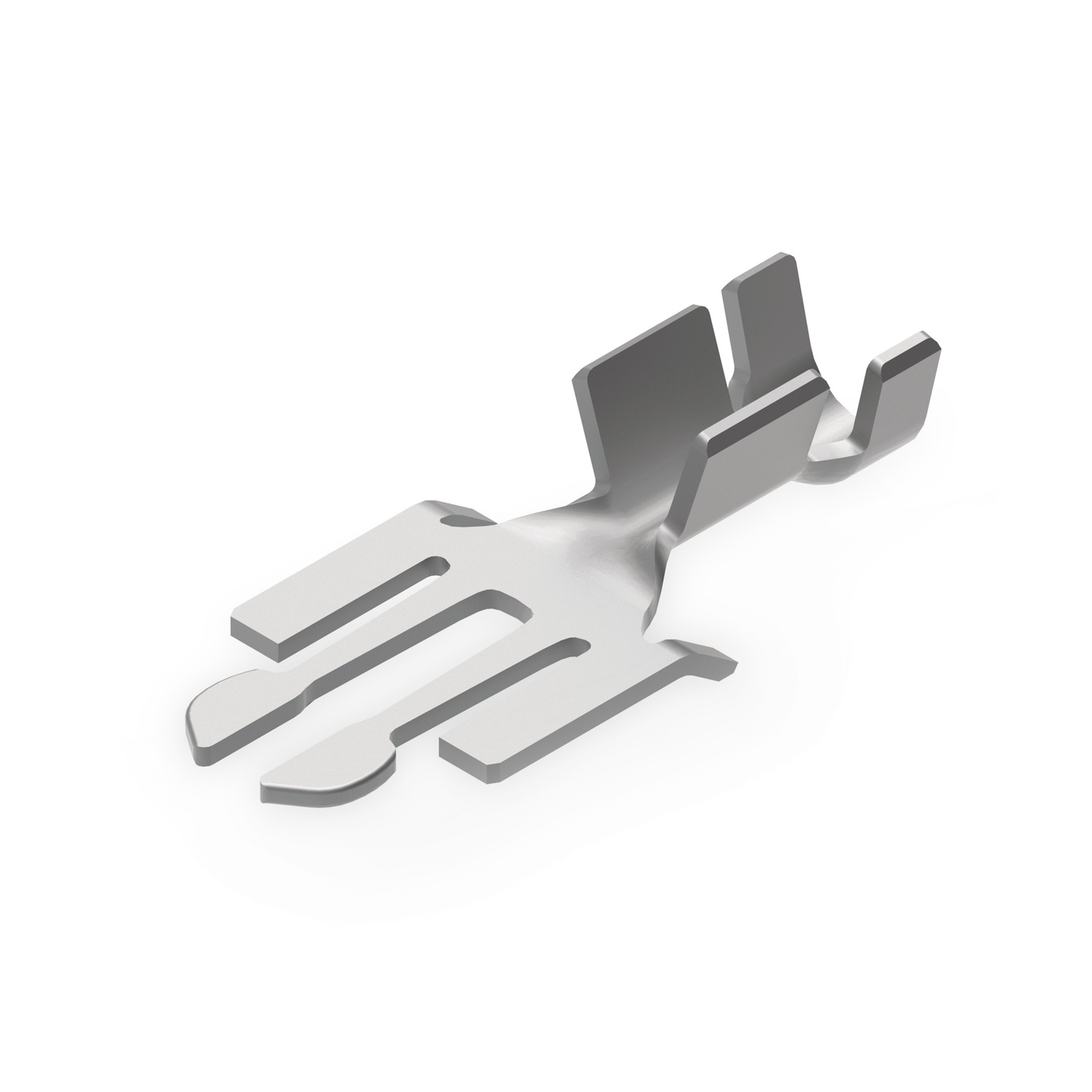

| Contact Material | Copper Alloy |

| Electrical Properties | |

|---|---|

| IR | 16 A |

Application Notes

Products

| Order Code | Datasheet | Downloads | Status | Qty. | IR (A) | Wire Section (Metric) | Wire Section (AWG) | Wire Insulation Range (Metric) | Wire Insulation Range (AWG) | Packaging | Manual Crimping Tool | Samples |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 49101504 | SPEC | – | Active i| Production is active. Expected lifetime: >10 years. | 20 | 16 | 0.75 to 1.5 (mm²) | 18 to 16 (AWG) | 2.0 to 2.5 (mm) | 0.080 to 0.100 (Inch) | Bag | 49100011 | |

| 49101503 | SPEC | – | Active i| Production is active. Expected lifetime: >10 years. | 500 | 16 | 0.75 to 1.5 (mm²) | 18 to 16 (AWG) | 2.0 to 2.5 (mm) | 0.080 to 0.100 (Inch) | Reel | 49100011 | |

| 49101502 | SPEC | – | Active i| Production is active. Expected lifetime: >10 years. | 10000 | 16 | 0.75 to 1.5 (mm²) | 18 to 16 (AWG) | 2.0 to 2.5 (mm) | 0.080 to 0.100 (Inch) | Reel | 49100011 |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | Qty. | IR (A) | Wire Section (Metric) | Wire Section (AWG) | Wire Insulation Range (Metric) | Wire Insulation Range (AWG) | Packaging | Manual Crimping Tool | Samples |

|---|

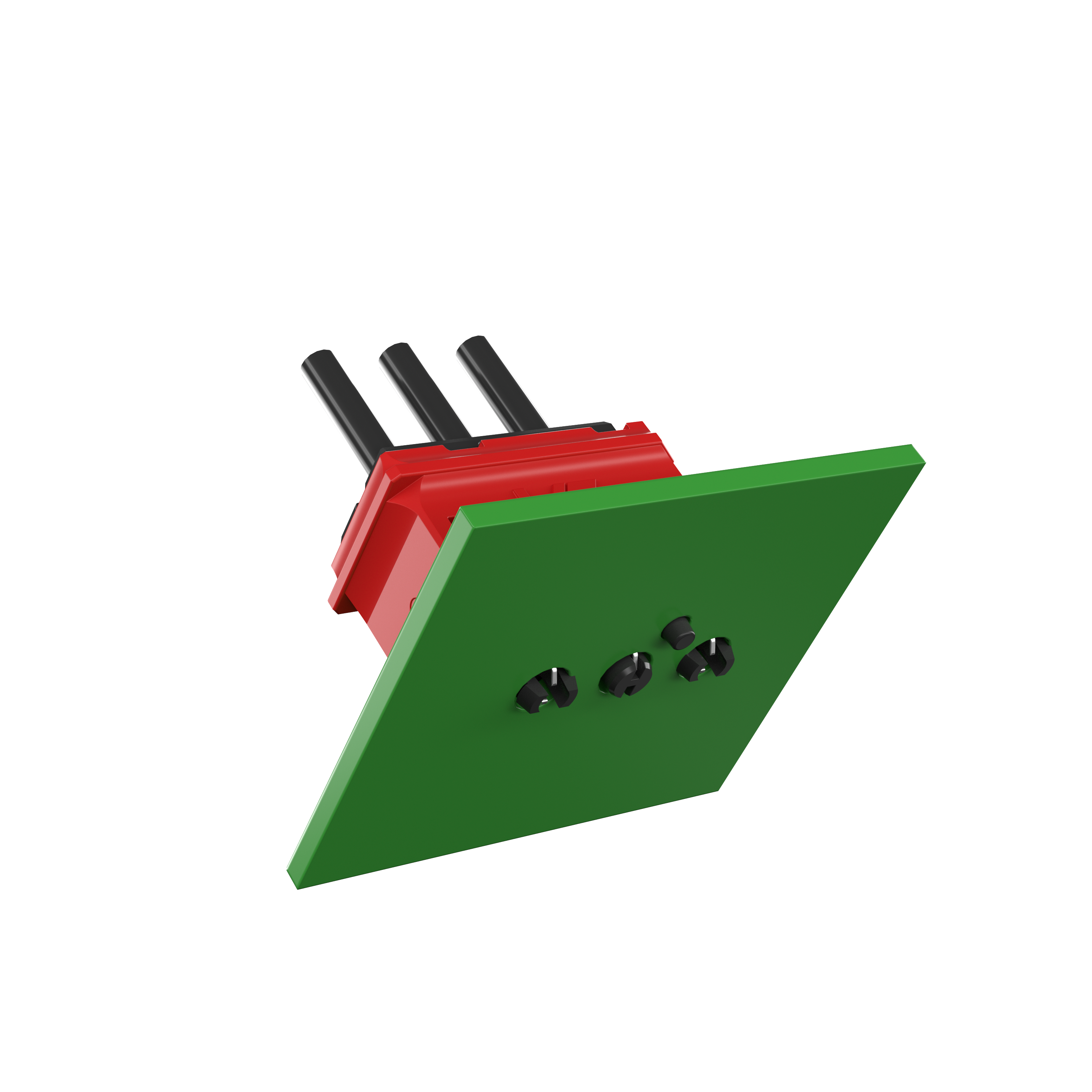

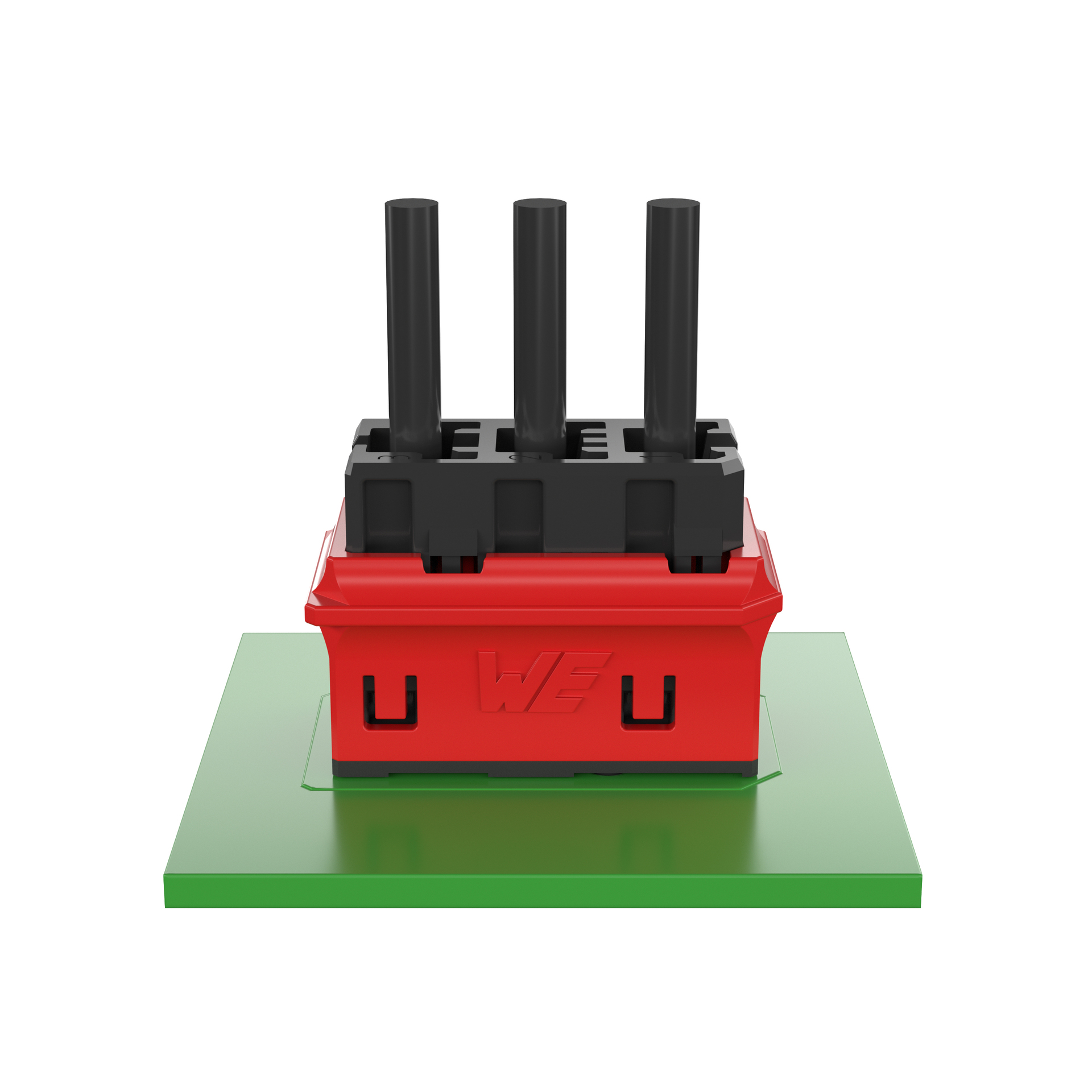

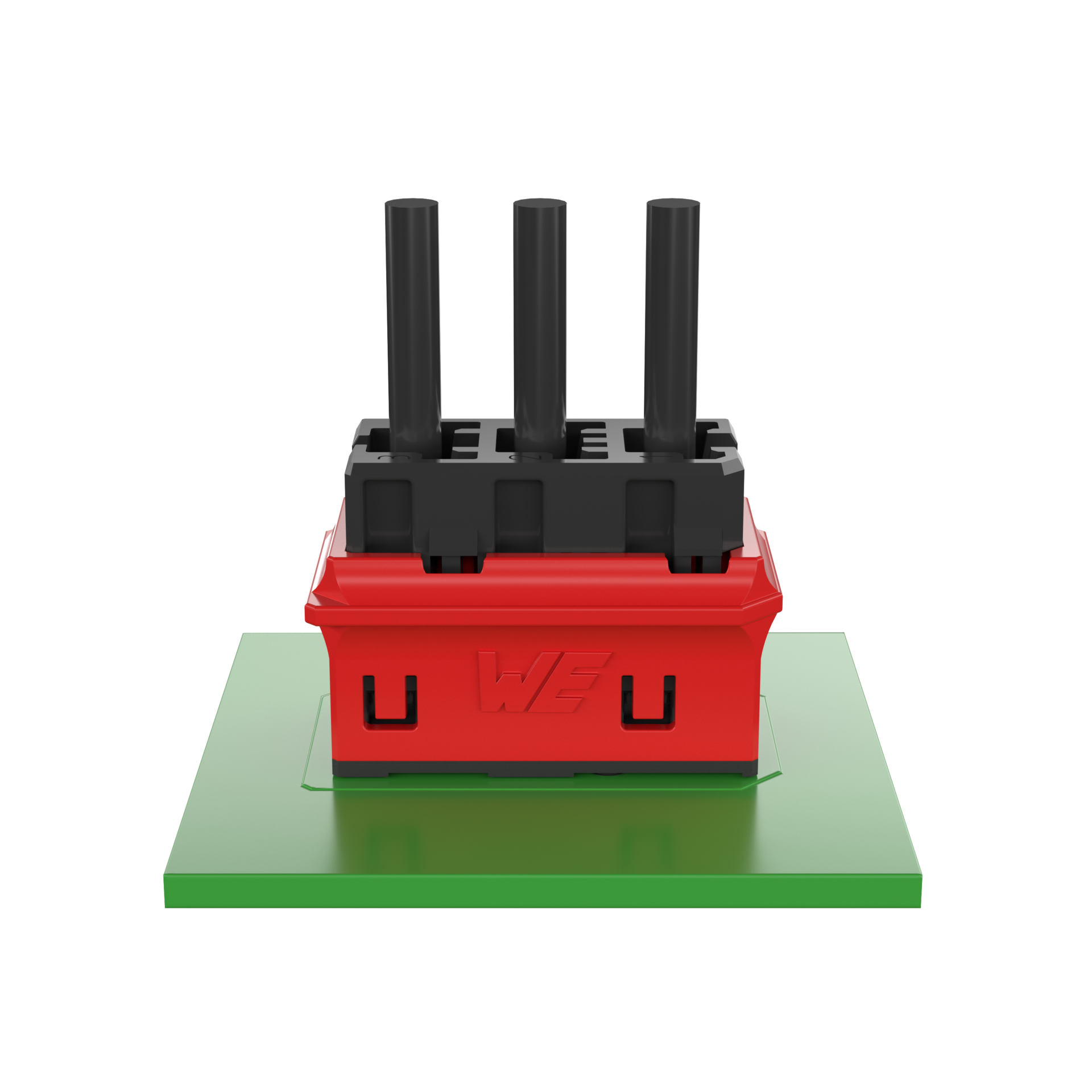

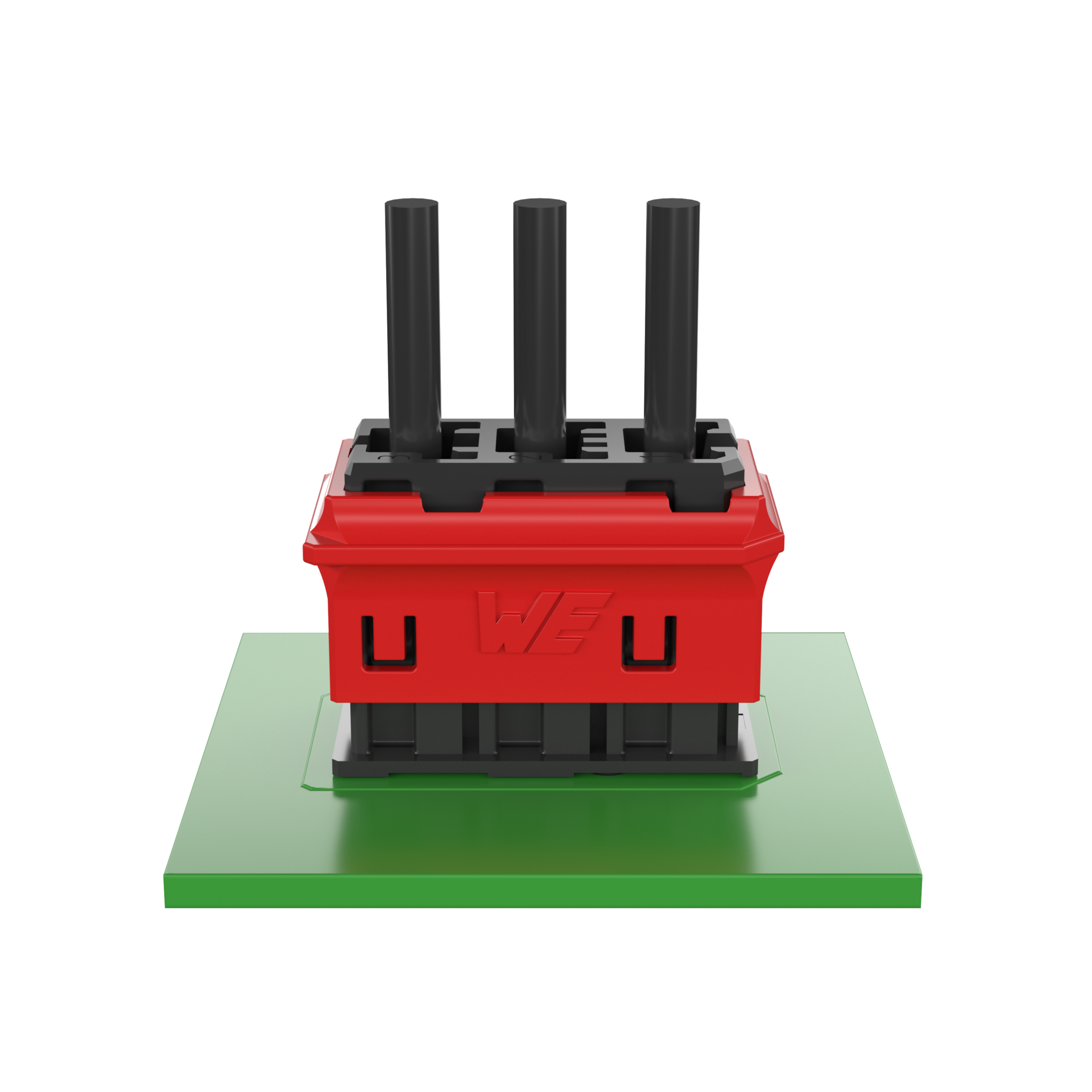

The new REDFIT WR-WSP connector

PLUG THE POWER. SOLDERLESS.

The new REDFIT WR-WSP connector

PLUG THE POWER. SOLDERLESS.

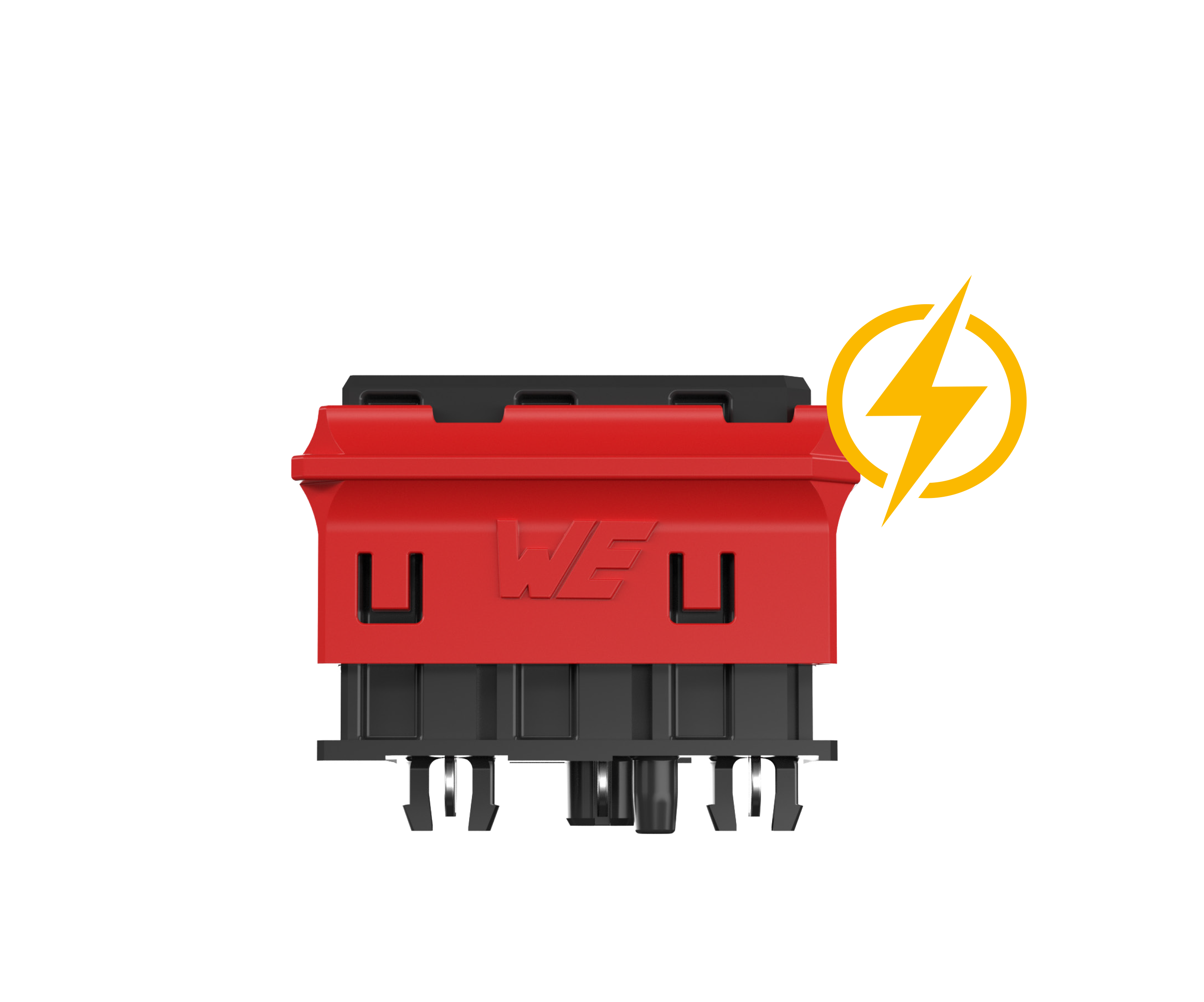

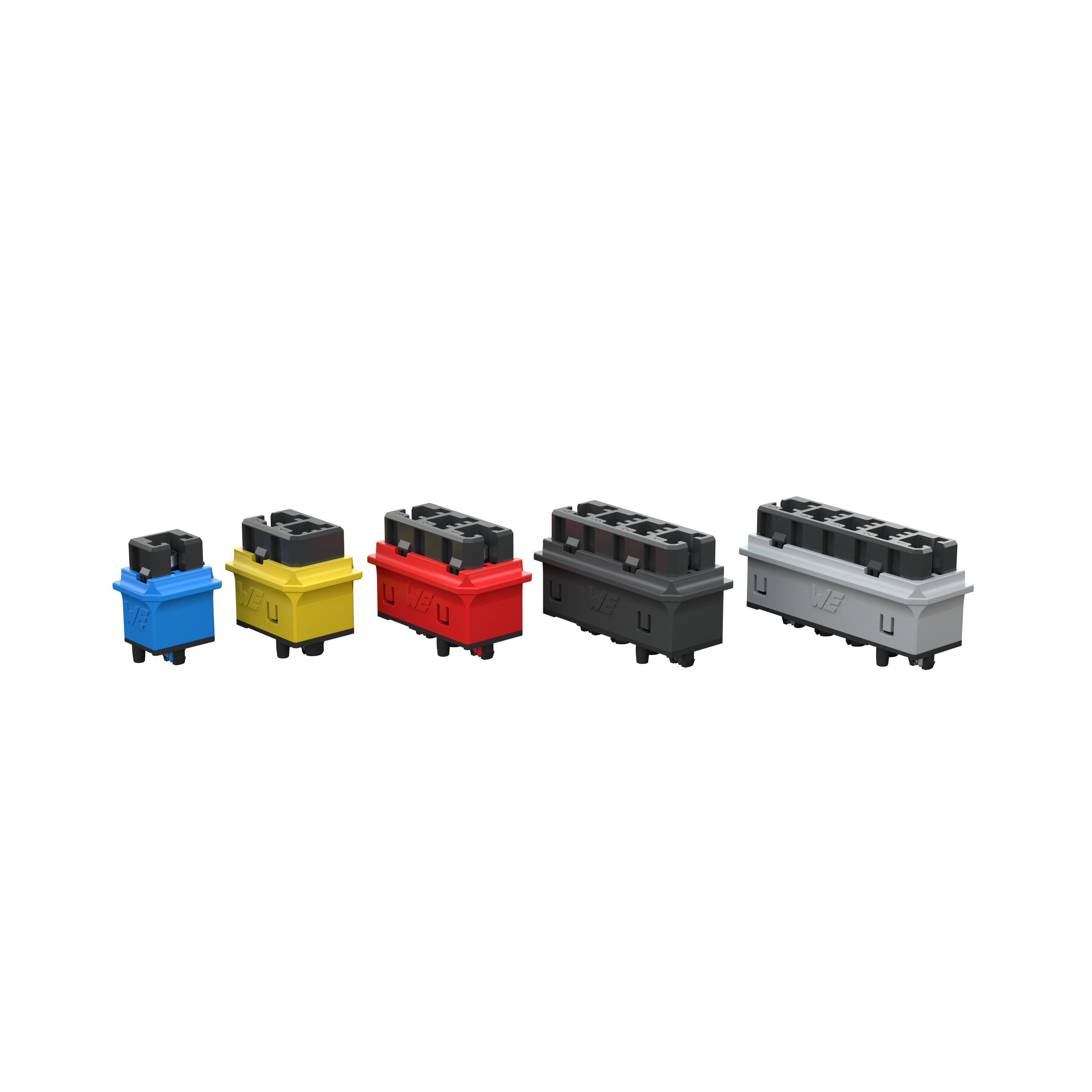

New solderless direct connector WR-WSP for power applications. It has integrated reverse polarity protection for the right mating and active locking with acoustic and haptic feedback.

This direct-plug connector is designed, developed and made in Germany. The mechanical stability is tested at accelerations of 10 g with current capability up to 16 Amps. Step motor or power supply for PCBs are two of possible applications.

All features at a glance

Mechanical stability at least 10 g

Mechanical stability at least 10 g

Active locking and reverse polarity pin

Active locking and reverse polarity pin

Tool free manual assembly

Tool free manual assembly

Current capability up to 16A

Current capability up to 16A

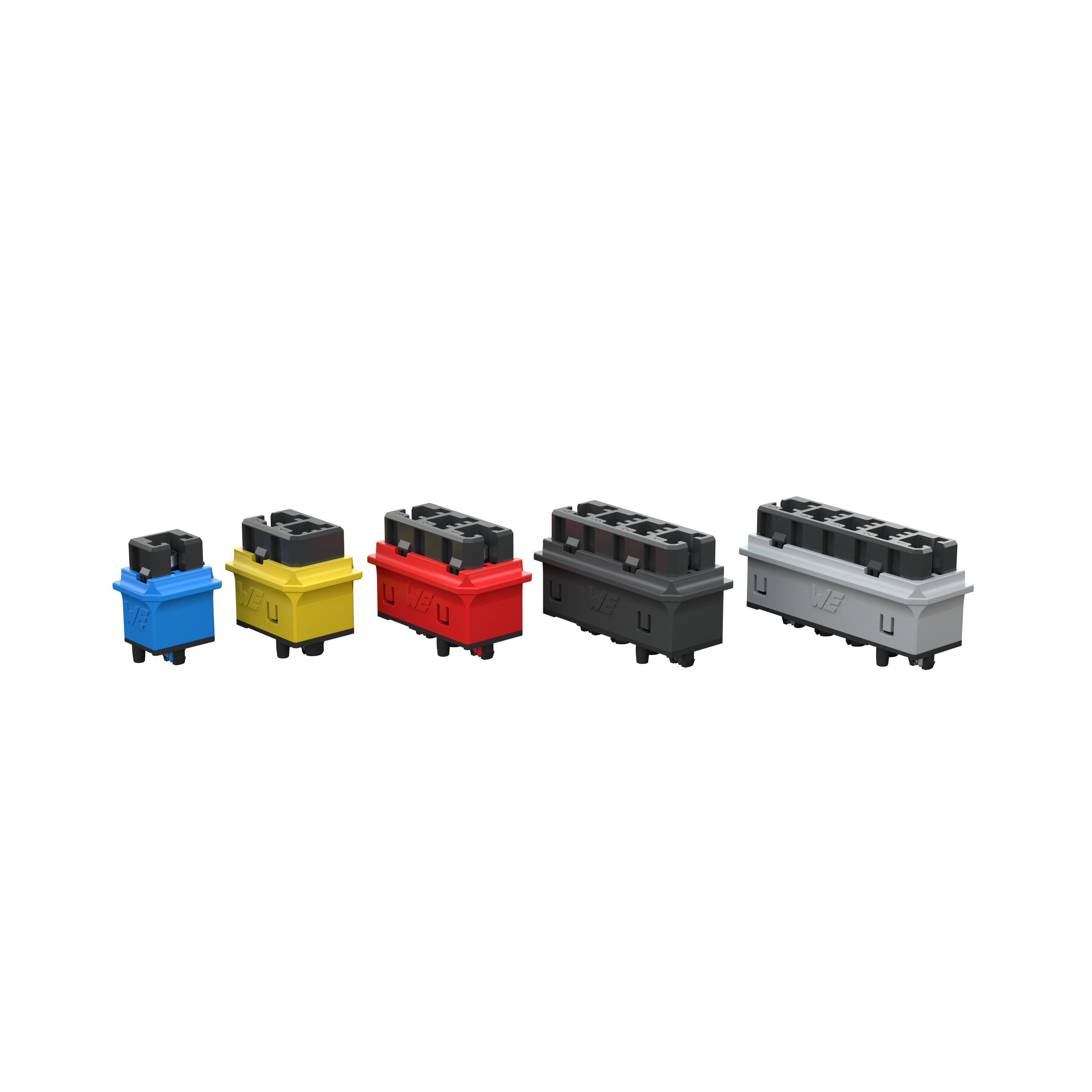

Color Coding

Color Coding

WHY SOLDERLESS?

WHY SOLDERLESS?

The entire process of soldering is associated with handling costs for each individual part on the pcb. Additionally, at some applications, the power connector is the only product in THT technology, so an additional hand-soldering or individual wave soldering makes the whole process more complex and thus more cost-intensive.

In addition, a classic connector solution requires two components - one on the cable and one on the PCB. By using SKEDD technology, components are reduced and additional processes are eliminated, resulting in time and cost savings in production.

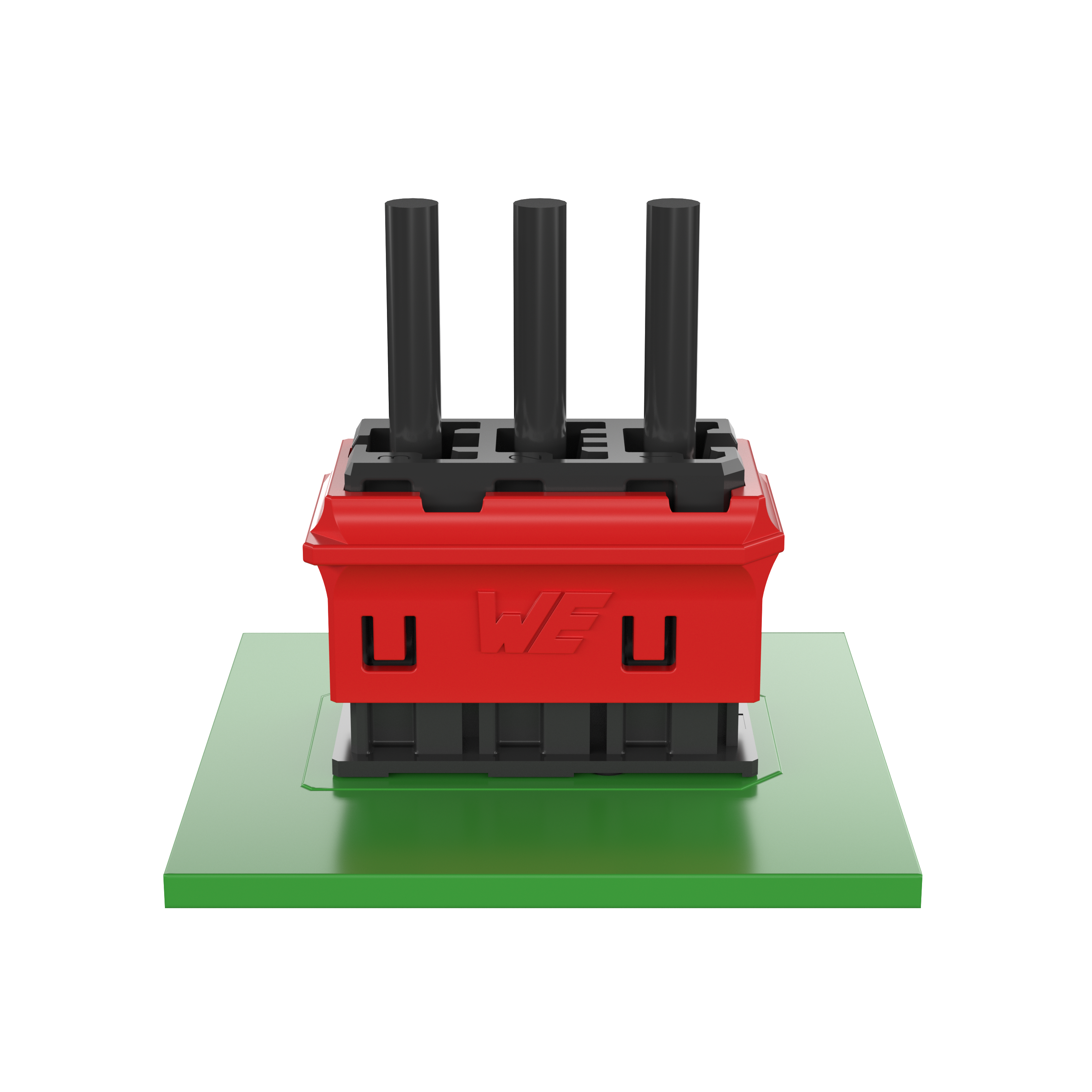

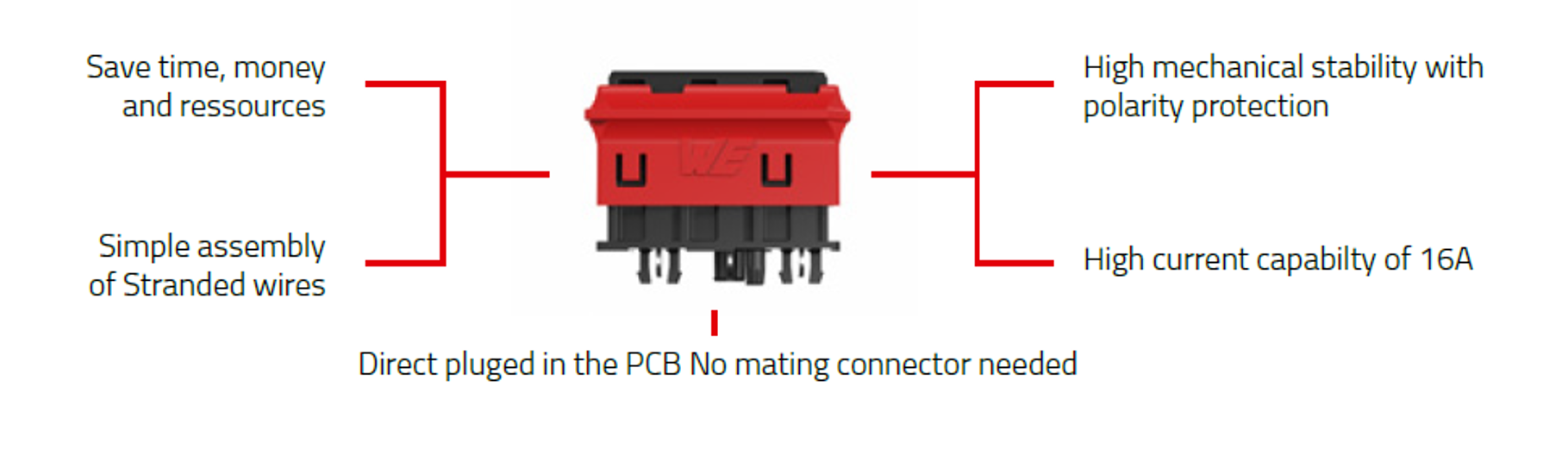

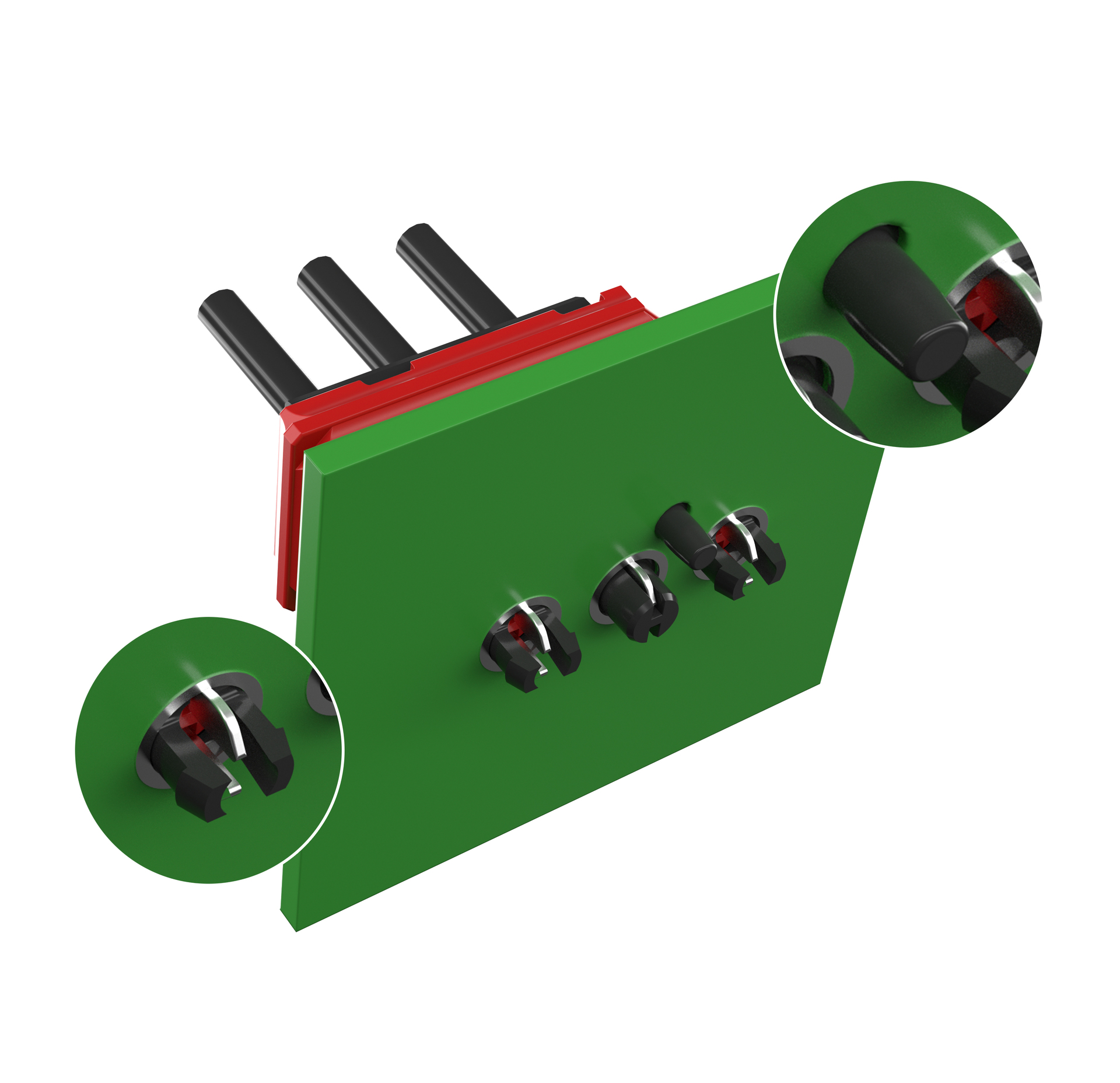

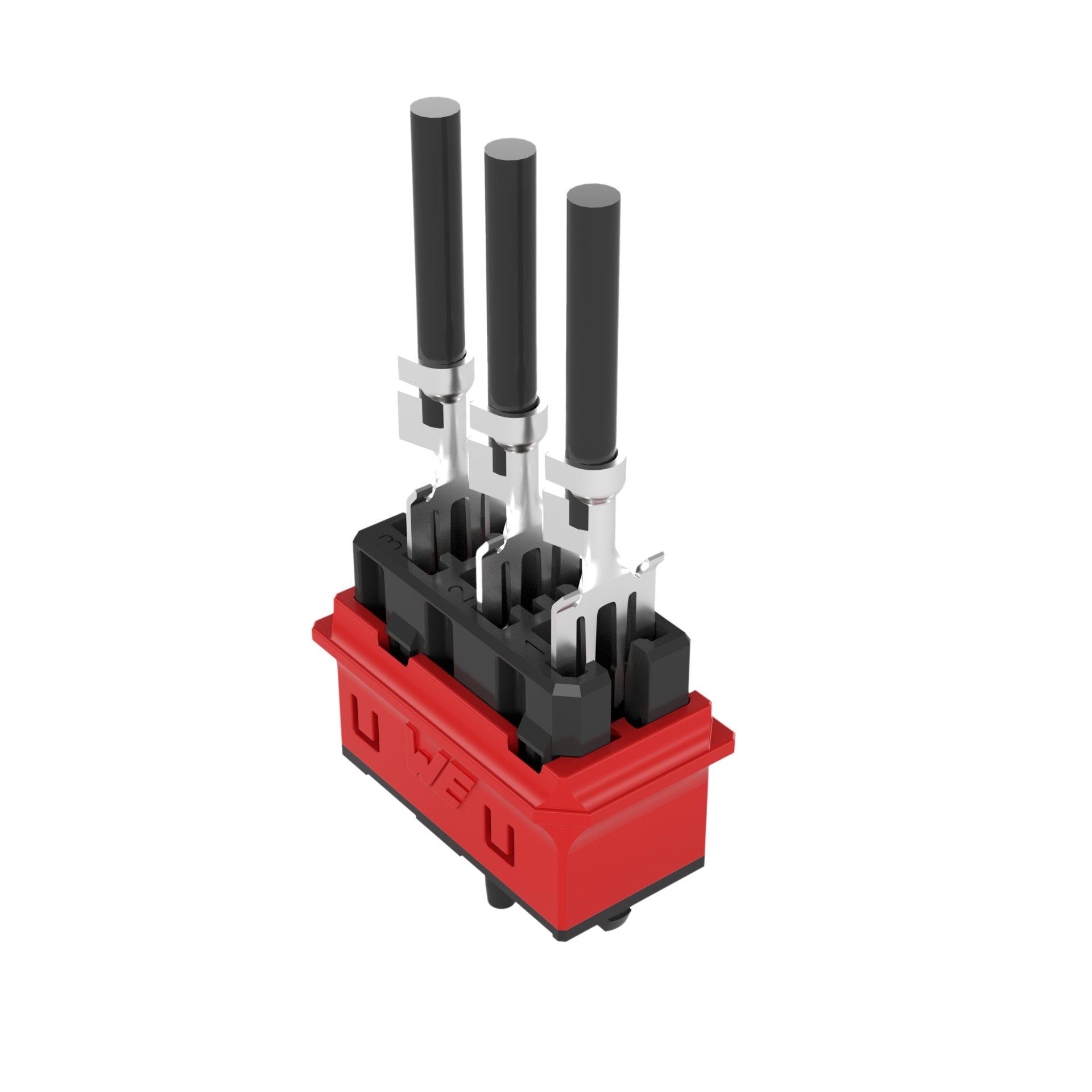

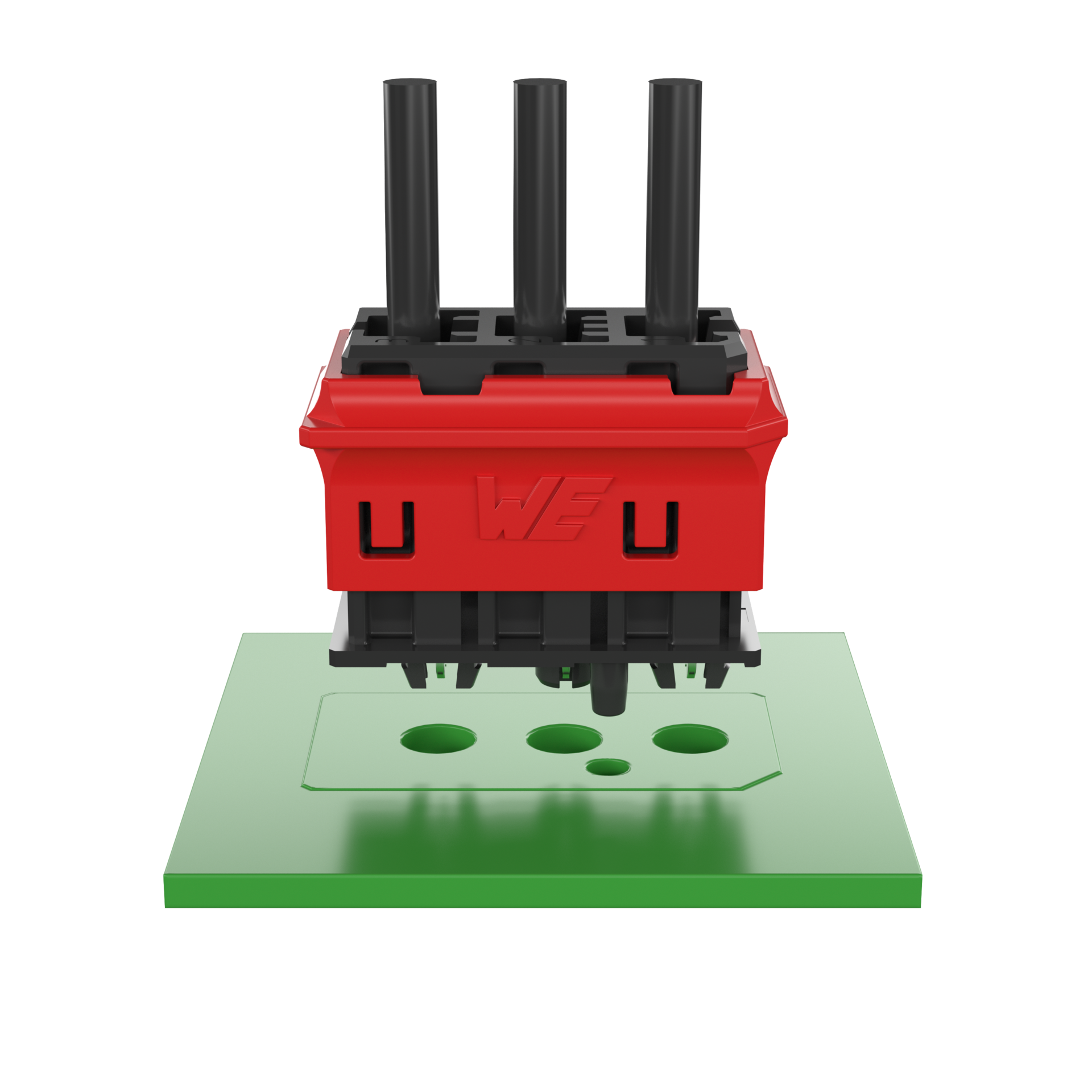

Explanation of the system components

Crimp contacts with different cross sections available

Slider fixation of the connector on the PCB with acoustic and haptic feedback

Housing with integrated reverse polarity protection

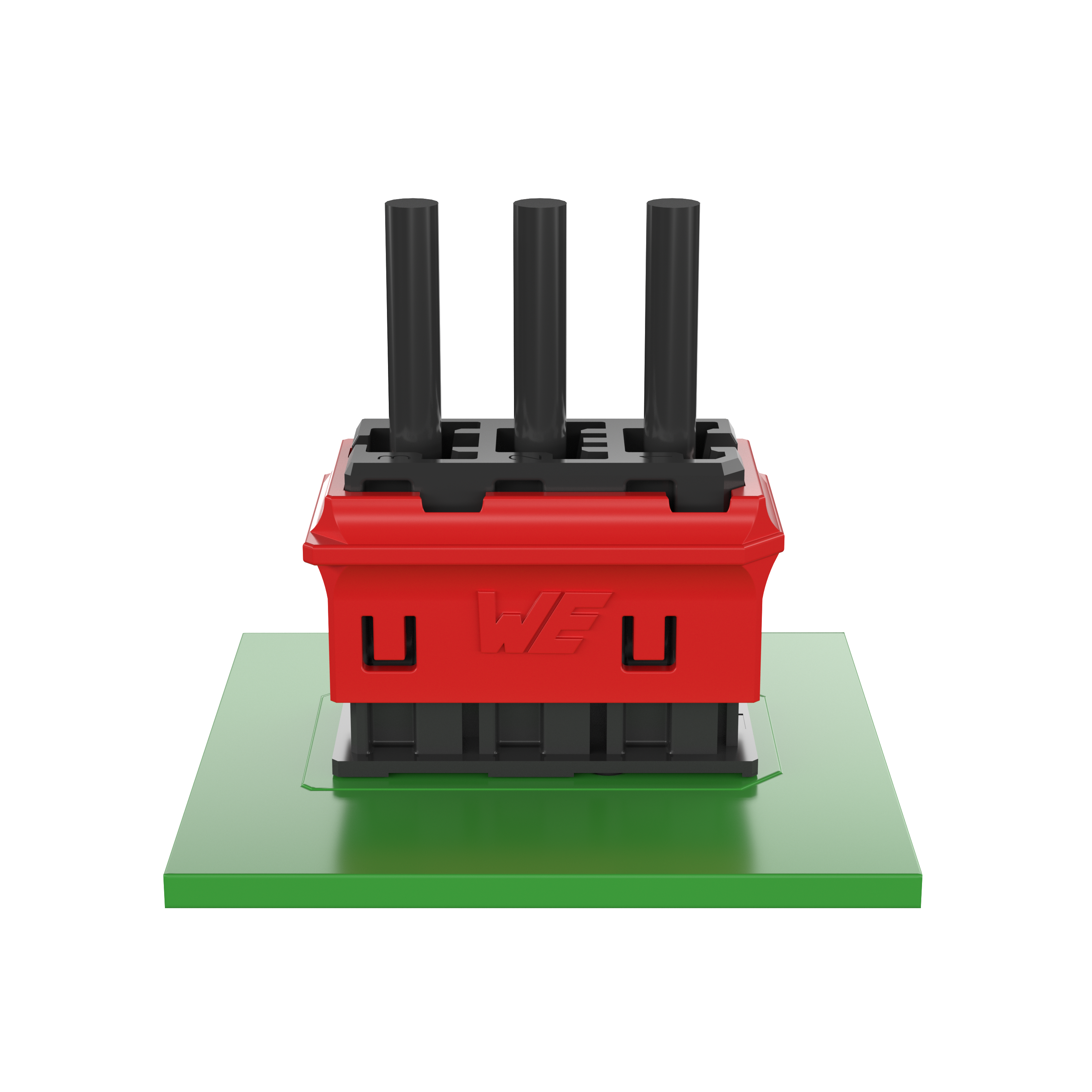

Mating Process

Due to the design of the plastic body, the crimp contacts fit smoothly in. Take care, that the contact locks with an audible „click“ in place.

Now insert the connector into the PCB layout. There is no big force needed due to the flexible SKEDD contact design and the expanding rivet design of the housing.

Final step ist to click the connector in the PCB. Therfore just move the slider down until the audible „click“. Now the maximum holding force is ensured.

Unmating Process

To remove the connector from the PCB just move the slider up. The locking mechanism releases.

Now the pullout force is very low due to the flexible SKEDD contact design and the expanding rivet design of the housing.