Shielding & Grounding

Shielding Gaskets

In the near field of an electric noise source, the electric field has a high impedance. A low-impedance shielding cabinet covering the critical component will act as a sacrificial capacitor plate to divert the noise back to it`s reference ground.

Grounding

Metallic housings are often used as the reference star point for RF noise. To divert interfering signals from the PCB to the chassis, a low-impedance path has to be strategically designed and implemented using e.g. steel spacers or EMI contact fingers.

EMC Tapes

A fully conductive housing is often meant to act as a Farraday cage to shield the PCB from the outside world. Machining processes, such as stamping, will leave some edges open, wide enough for slot antennas to form. Conductive tape can close the gaps between adjacent parts to improve shielding properties.

Magnetic Shielding

Current-driven noise sources emit a low-impedance magnetic field. High-permeability shielding sheets create a mismatch, absorbing and reflecting much of the interference.

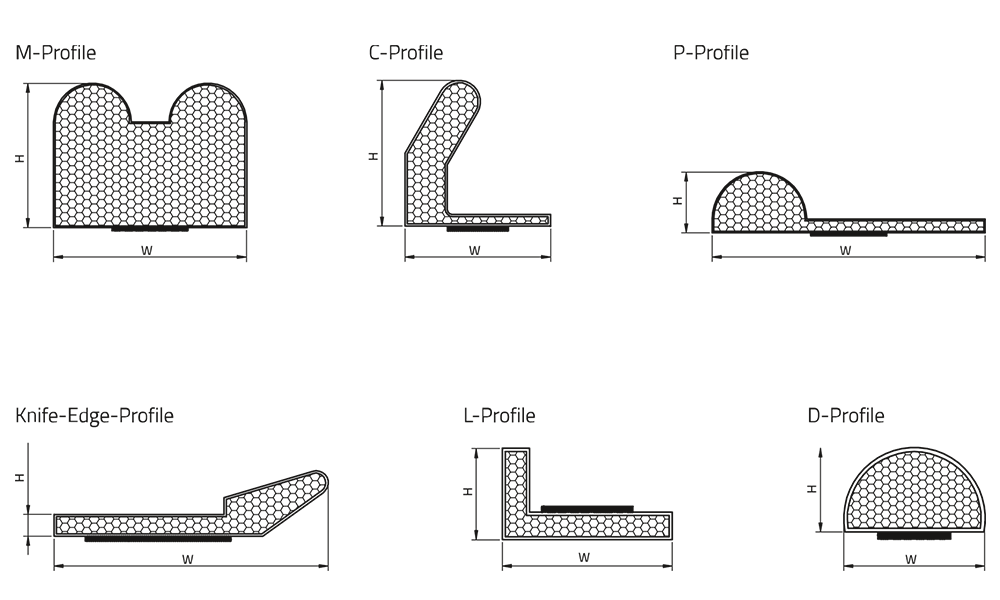

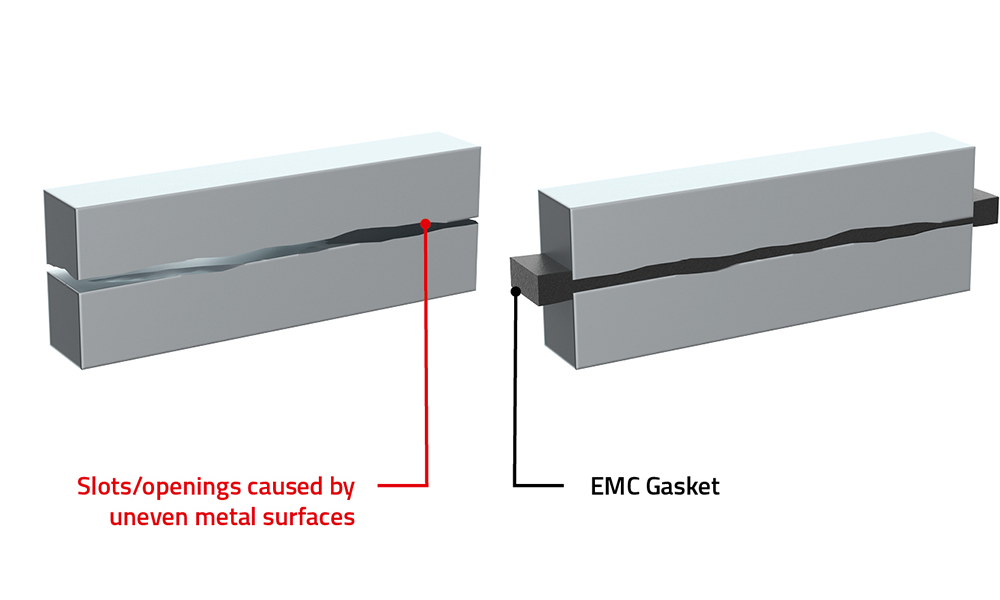

EMC Gaskets

Even in fully metallic housings there needs to be a door or hatch for placing the electronics inside. To close the small gaps and to prevent interfering signals, from leaking, we offer EMC gaskets for various assembly conditions.

Short Introduction to Shielding & Grounding

Shielding and grounding are distinct EMC measures. Electric shielding blocks electric fields generated by AC volt in high-impedance systems using conductive materials. Magnetic shielding redirects fields caused by high-frequency currents through low-impedance paths, using ferromagnetic materials.

Grounding provides a reference and low-impedance return path for these currents, minimizing noise coupling between circuits.

Learn More About Shielding & Grounding

-

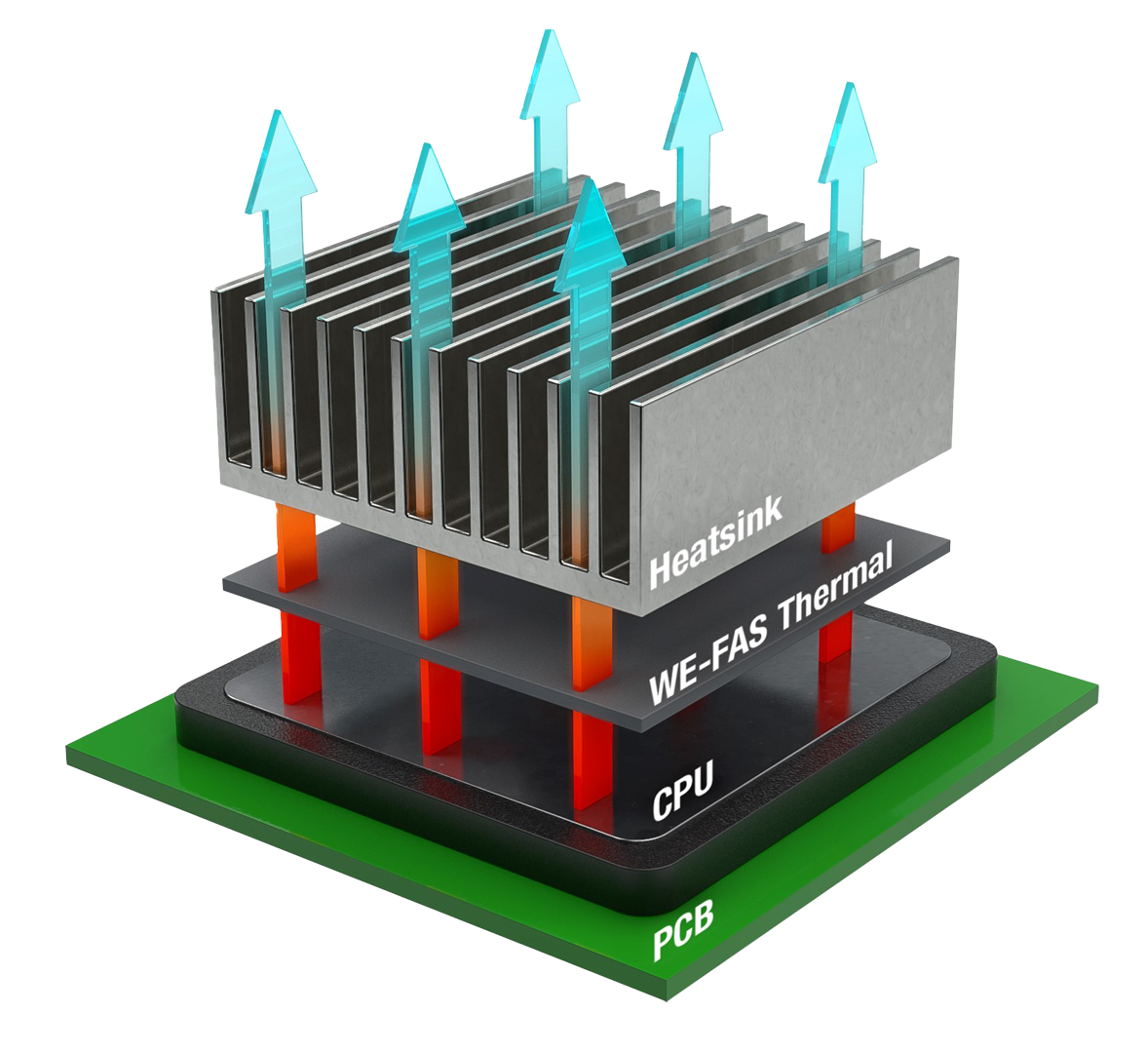

In enclosures, interference signals can be significantly attenuated using high-permeability films, as shown in the image.

-

The films WE-FSFS/WE-FAS protect communication by concentrating the magnetic field. Frequency shifts through narrow metal surfaces are prevented.