Applications

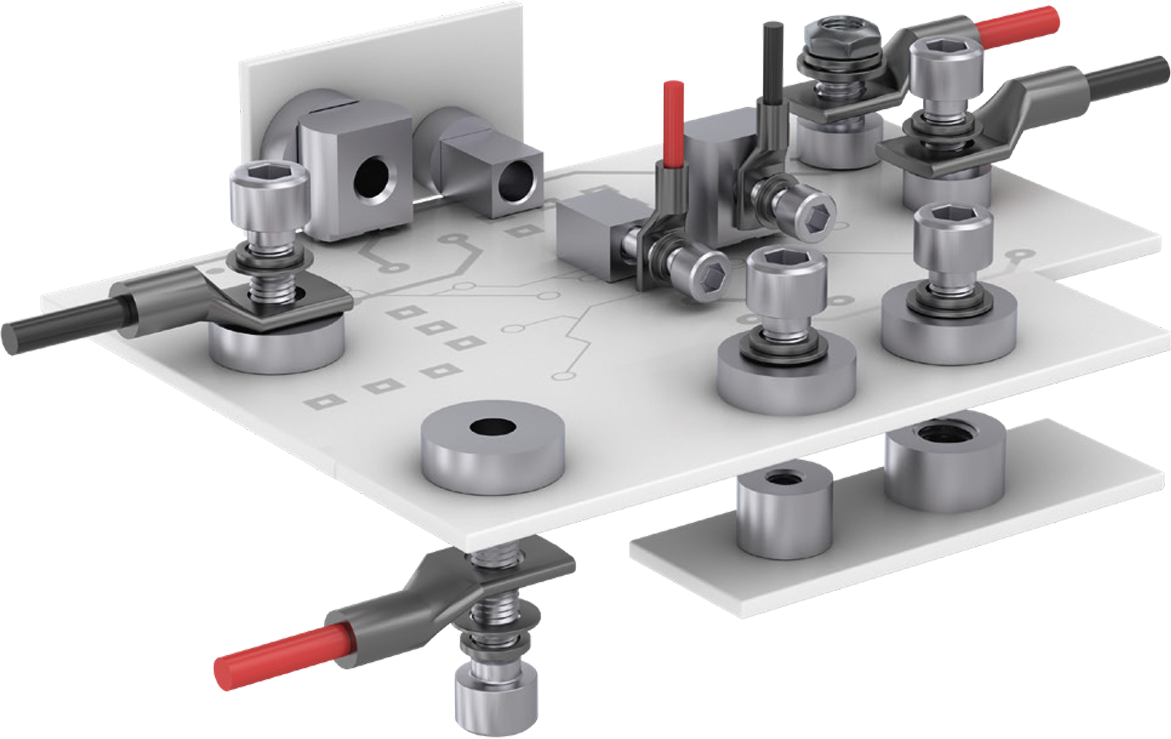

- SMT Power Elements combine the advantages of SMT mounting in conjunction with high current technology. The parts can be mounted fully automatically from the reel to the circuit board with all other SMT components.

| General Information | |

|---|---|

| Material | Brass |

| Surface | Tin |

| Operating Temperature | -55 °C up to +150 °C |

| Electrical Properties | |

|---|---|

| IR | 50 A |

| Packaging Properties | |

|---|---|

| Packaging | Bulk; Tape and Reel |

Application Notes

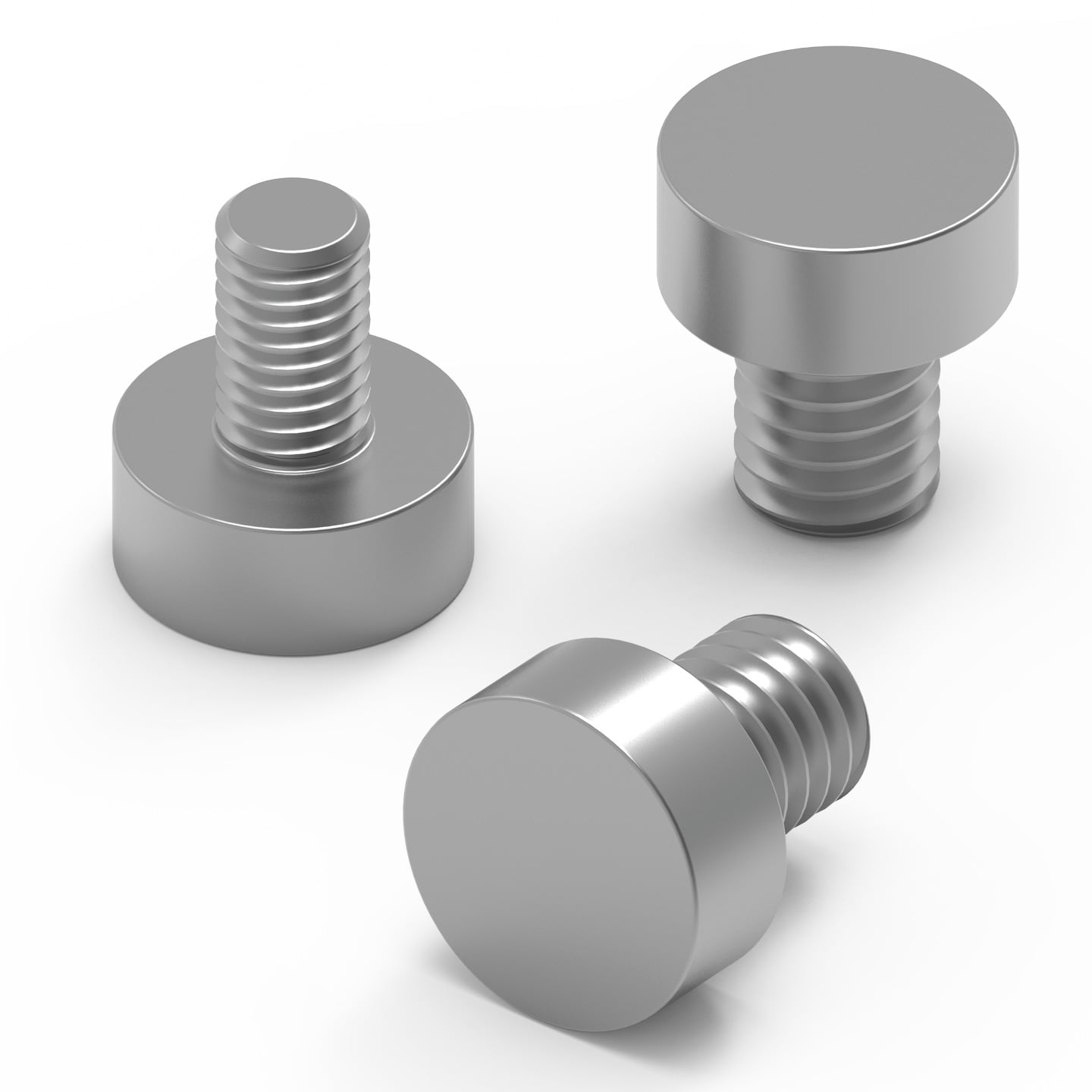

Products

| Order Code | Datasheet | Downloads | Status | H (mm) | Ø OD (mm) | IR (A) | To | Tlo (mm) | Design Kit | Samples | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7466213 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 8 | 7 | 50 | M3 | 5 | 746701 | |

| 7466214 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 8 | 7 | 50 | M4 | 5 | – | |

| 7466213R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 8 | 7 | 50 | M3 | 5 | – | |

| 7466214R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 8 | 7 | 50 | M4 | 5 | – |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | H (mm) | Ø OD (mm) | IR (A) | To | Tlo (mm) | Design Kit | Samples |

|---|

Assortments

Articles from this product series can be found in the following assortments:

Videos

Würth Elektronik Webinar: REDCUBE - Everything about high currents on the printed circuit board

Videos

Würth Elektronik Webinar: REDCUBE HighPower Terminals for ampacity of 50-500 A