PURE.flex PCBs

Mechatronics optimizes your interfaces

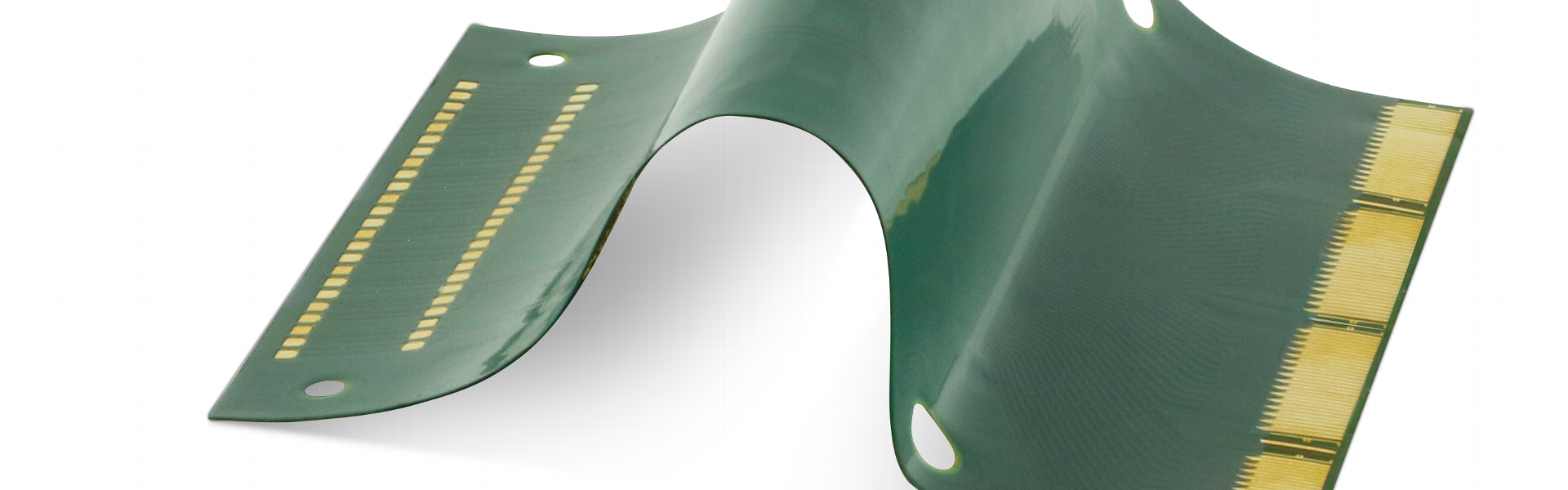

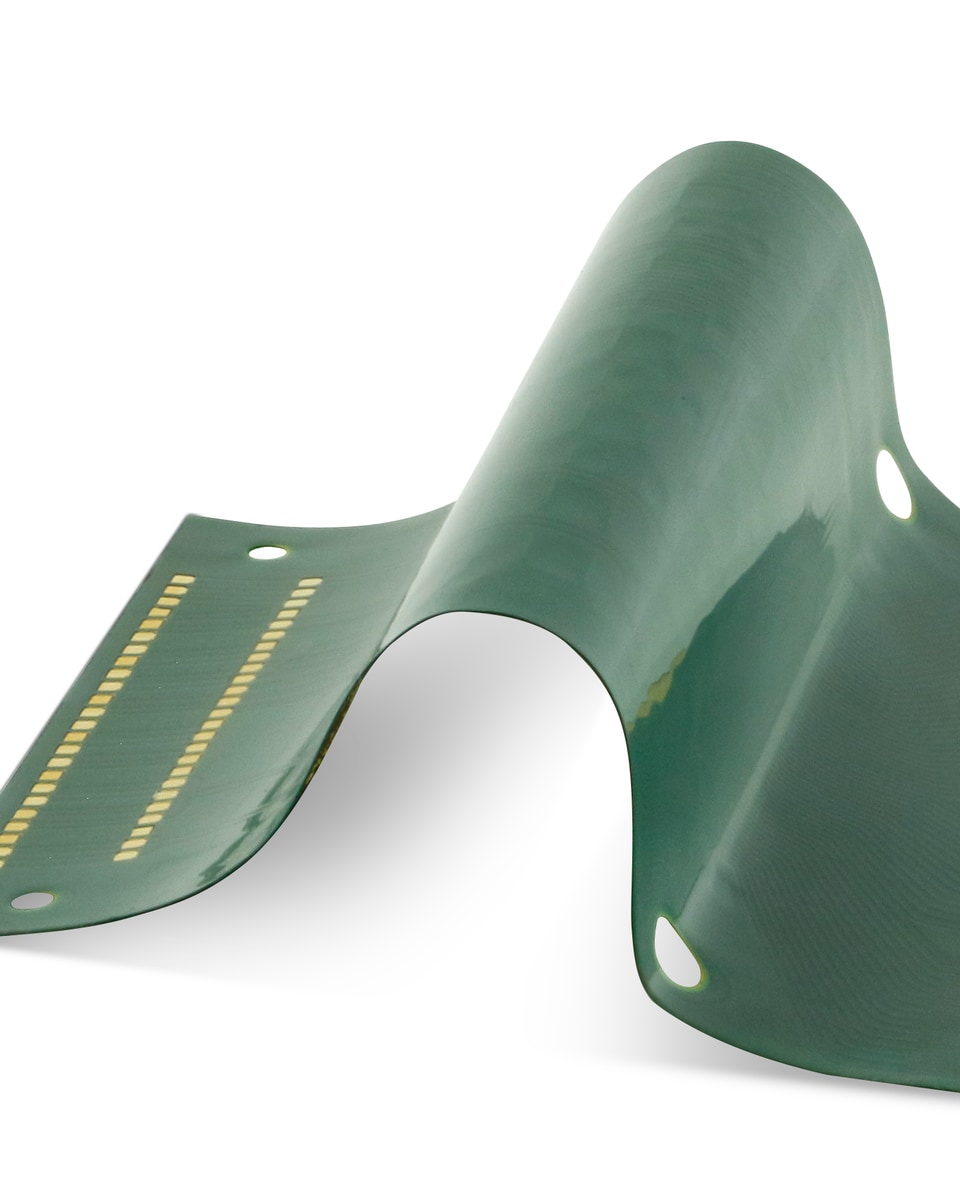

Flexible films made of polyimide with a typical thickness of 50 μm are chemically stable and high-temperature resistant materials. In combination with copper cl adding, this base material can be used to manufacture flexible printed circuit boards with one or two copper layers, which can be processed using all common soldering methods. Partial rigidizing with glued-on stiffeners allows the use of standard SMD components. Thanks to this flexibility, small installation spaces can be used very efficiently. The use of special copper qualities gives the circuits outstanding properties for dynamic bending loads. Clever mechatronic systems save interfaces and improve reliability at lower system costs.

Advantages of Würth Elektronik PURE.flex technology

Relevant parameters for production-ready PCB design

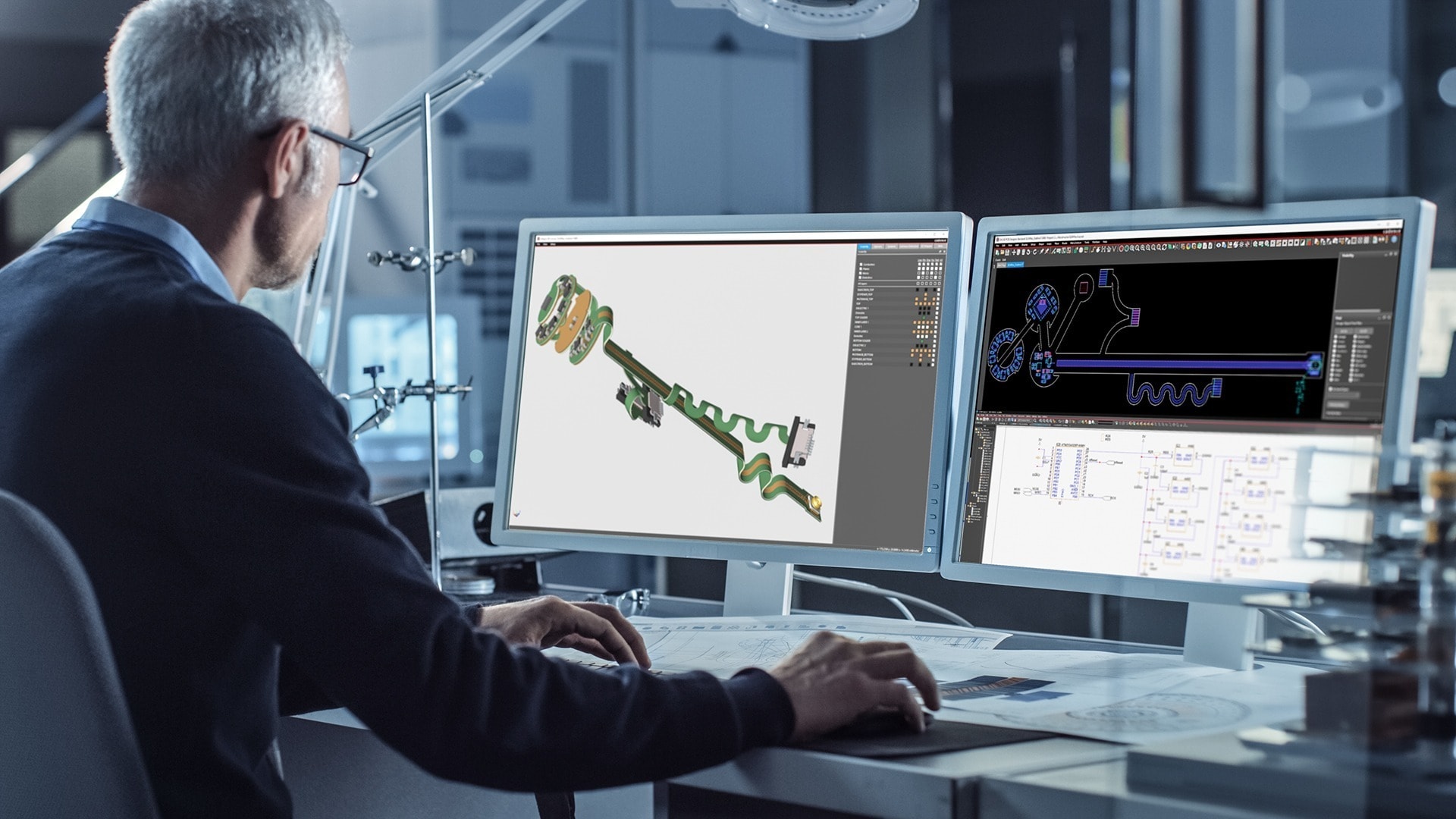

Modern printed circuit board solutions are more than just connecting elements. They are the key to progress in electronics. With this in mind, we actively support our customers in development and also offer our own system solutions with electronic functions.

The PURE.flex design rules include all the important parameters you need to make your project successful:

In this design guide you will find an overview of all variants of our flex solutions. In addition, our specialists have summarized valuable design tips for you here. This will help you bring your application to success reliably and safely.

Get started with your layout faster - thanks to standardized stackups

With these stackups, you automatically use market-customary and cost-optimized standards and avoid expensive custom builds. In addition, high-quality and cost-effective production with shorter delivery times is made possible because stock materials are used and standardized production processes are followed.

Here you will find our standard layer lay-ups for PURE.flex in digital form for import into your EDA software and as PDF.

Basically all layouts are designed according to IPC-2223 Use A (Flex-to-install).

Drying is required before soldering!

Flexible printed circuit boards made of polyimide absorb moisture from the air even when originally packaged under normal room conditions. Since a dried polyimide film will have reached its moisture saturation level again after just a few hours, the logistics must also be checked and adjusted if necessary.

This prevents damage from delamination, bubbling and tearing that can otherwise be caused by absorbed moisture during soldering.

Did you know that your PCB design is of great importance in this context? Please read our detailed drying instructions.

To document and optimize the drying process, you can use our planning sheet for support.

Learn more about the background and qualification of a suitable drying process: A detailed application note 'Physics of moisture & process of drying printed circuit boards' can be found here.

You also have the option to re-watch our webinar 'Moisture in printed circuit boards - Developing an efficient drying process' or download the corresponding webinar presentation.

Contact us