LTSpice files

Characteristics

Customized screw capacitors

- Mounting style: Screw

- Interested? Send us your request for customized screw capacitors

Applications

- Energy storage

- Renewable Energy

- e.g. Industrial drives, frequency converters, welding

Products

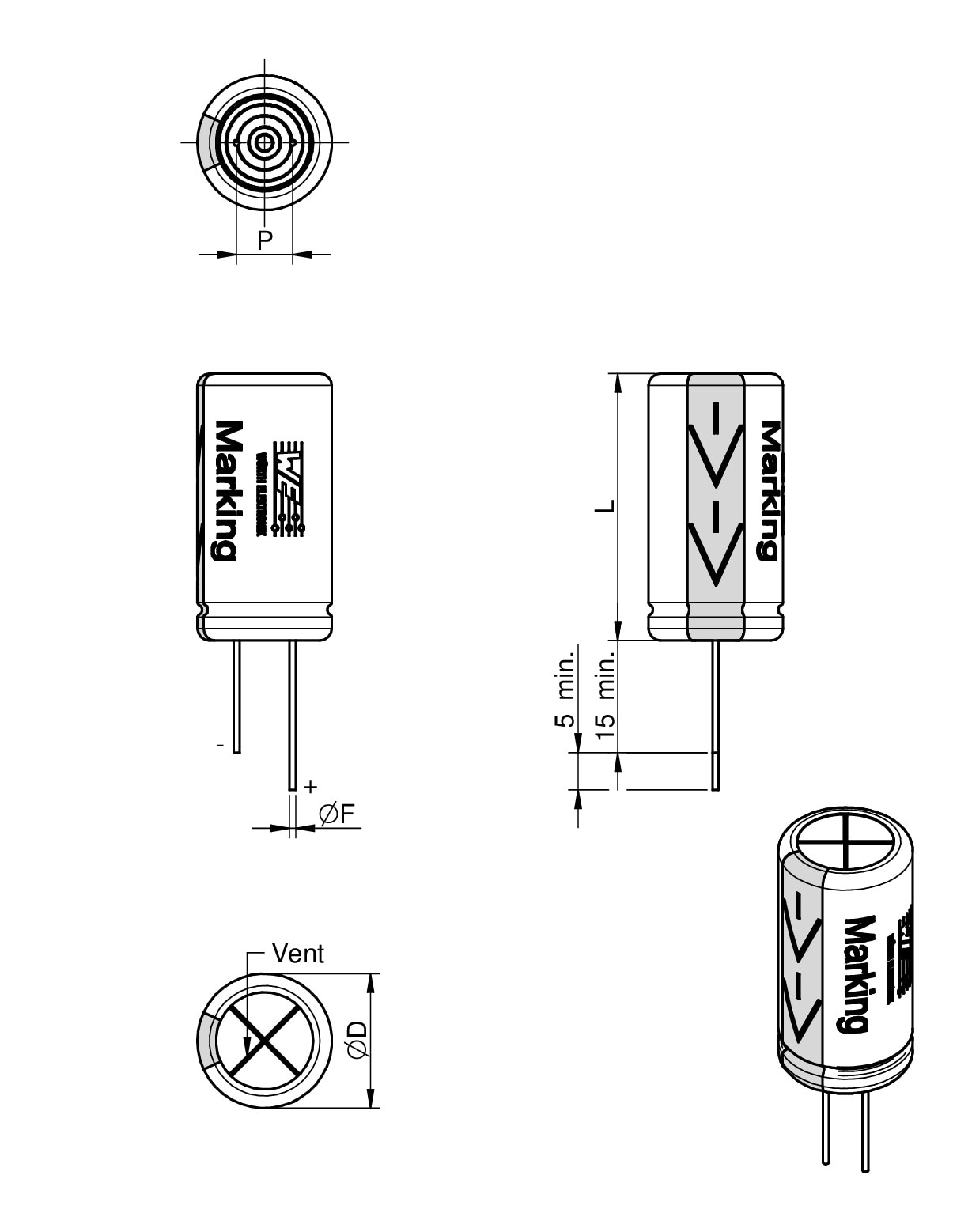

| Order Code | Datasheet | Simulation | Downloads | Status | Description | C | VR (V (DC)) | ILeak (µA) | DF (%) | Pitch (mm) | Ø D (mm) | L (mm) | Samples |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 862023186001 | SPEC | 7 files | Active i| Production is active. Expected lifetime: >10 years. | Example item. For customized solution please use the inquiry form. | 1600 µF | 360 | 1600 | 15 | 12.7 | 35 | 66 |

| Order Code | Datasheet | Simulation |

|---|---|---|

| 862023186001 | SPEC |

| Samples |

|---|

| Order Code | Datasheet | Simulation | Downloads | Status | Description | C | VR (V (DC)) | ILeak (µA) | DF (%) | Pitch (mm) | Ø D (mm) | L (mm) | Samples |

|---|

Customer-specific solutions

Aluminum Electrolytic Capacitors

Screw Types

Customer-specific solutions

Aluminum Electrolytic Capacitors

Screw Types

In addition to our Aluminum Electrolytic Capacitors catalogue portfolio, Würth Elektronik also offers aluminum electrolytic capacitors in screw type version. Due to the various and different demands we offer this component as a customer-specific solution. Our screw type solutions for your product makes it possible to have desired electrical criteria and dimensions based on your demand. Please get in contact with our technical sales for details and offers or fill out the inquiry request form: