Power Supply

Capacitors

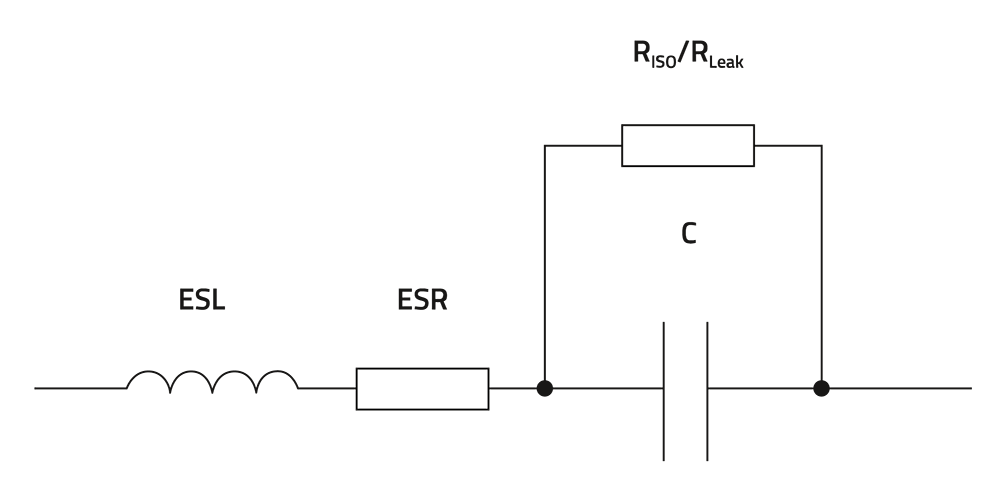

Due to the high voltages in the DC link circuit two different technolgies are suitable. Electrolytic capacitors offer a higher capacitance, DC link film capacitors withstand a higher ripple current.

Terminal Blocks

Terminal block connectors (TBL) provide a secure and reliable way to connect wires in mains line assemblies. They allow for quick installation, safe handling of high-voltage connections, and flexible wiring options. Their robust design ensures durable connections for industrial devices.

Optocouplers

Optocouplers transfer signals between circuits while maintaining electrical isolation between the primary and secondary windings of a power transformer. In AC/DC converters they are used to provide feedback from the output side back to the primary-side regulator.

Assembly Solutions

Assembly solutions cover mechanical and electromechanical components that simplify PCB integration. These include spacers, mounting screws and fixing elements that deliver secure and proper mounting.

REDCUBE

REDCUBE terminals are high-current connectors designed for press-in mounting on printed circuit boards. They provide very low contact resistance and high mechanical stability for power transmission. With their robust construction, they are suitable for applications requiring high current carrying capability and efficient thermal management.

High Voltage Power Inductors

REDEXPERT helps you find the best power inductor for your SMPS and provide useful information regarding efficiency and temperature rise.

Offline Transformers

Offline transformers provide galvanic isolation and voltage conversion between the mains input and low-voltage circuits. Their design influences efficiency, EMI performance, and power density in AC/DC converters.

Topologies

Short Introduction to Power Supply

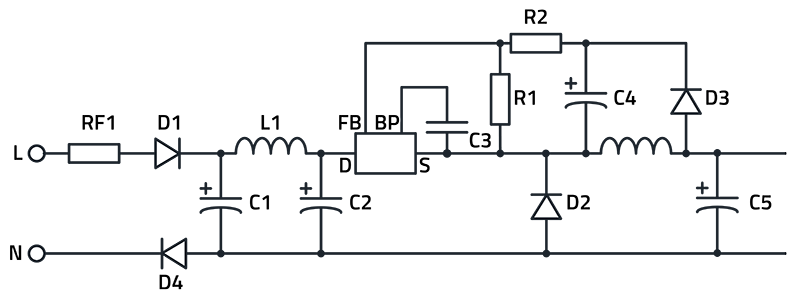

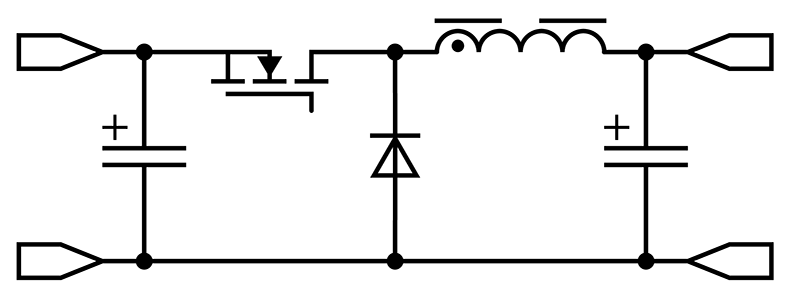

Modern electronics run on low DC voltages, but the grid provides AC (230 V or 110 V). AC/DC converters rectify, filter, and regulate it to provide safe, stable DC output. Depending on power level and safety needs, isolated or non-isolated topologies are used. Most modern designs use efficient switched-mode power supplies (SMPS) with an upstream rectifier. Since SMPS generate EMI, appropriate EMC measures are required to meet standards.

Learn More About Power Supply

-

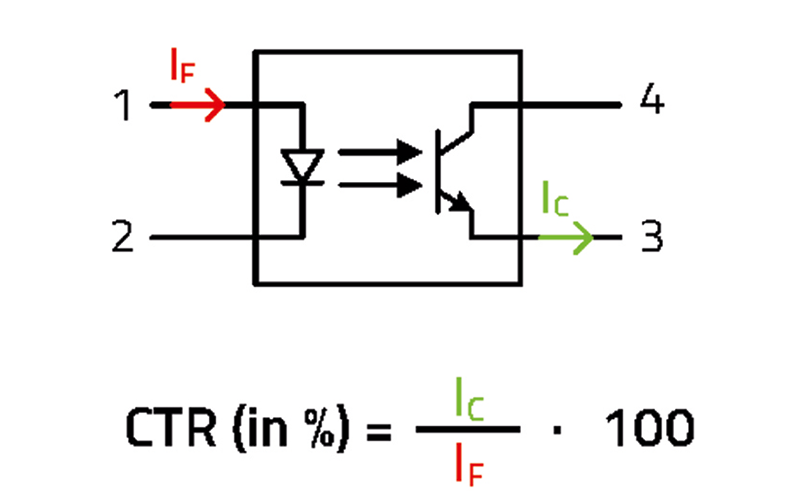

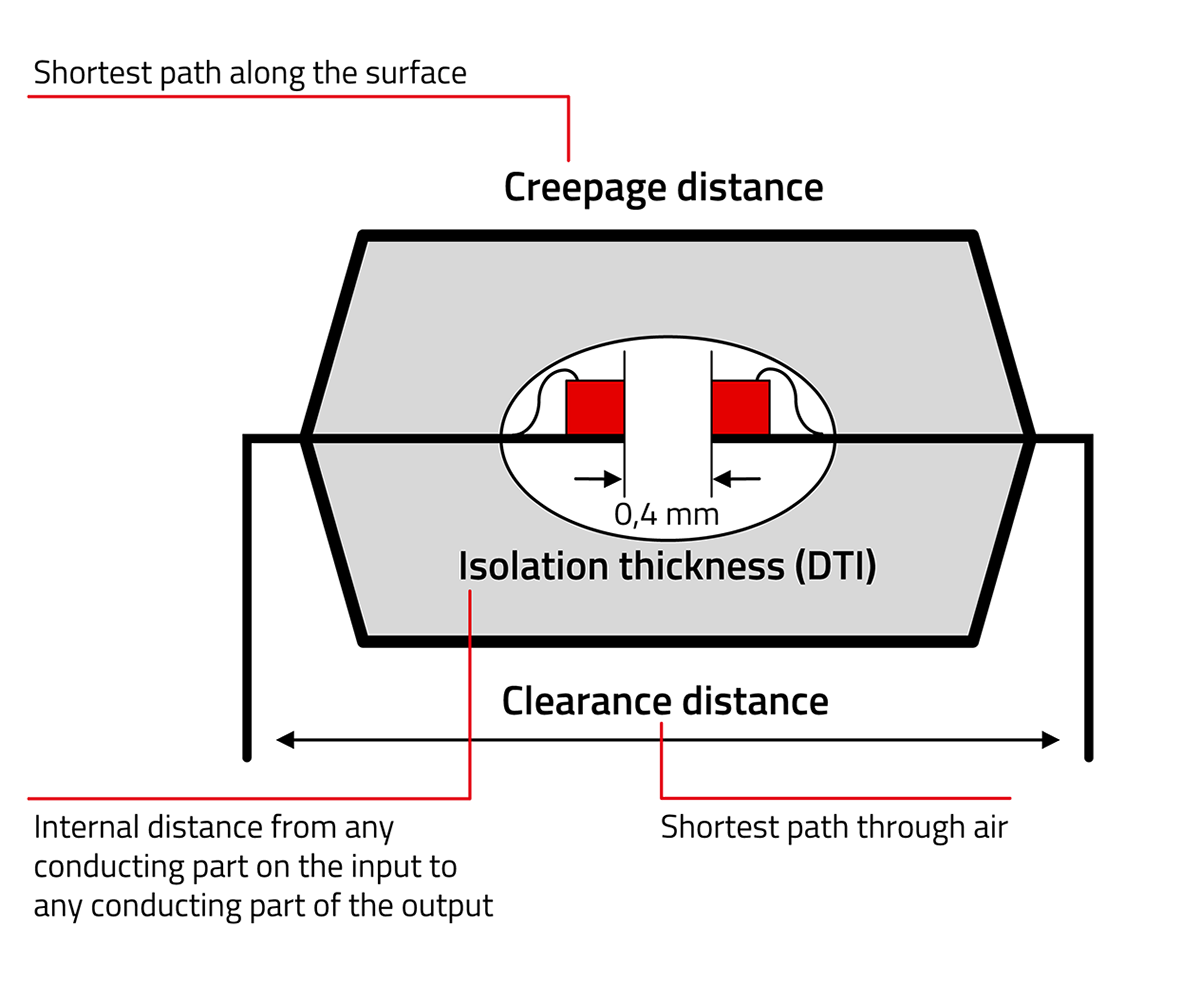

Optocouplers are frequently used in the control path of power supply circuits that require galvanic isolation between the primary and secondary sides. The most important parameters include the Current Transfer Ratio (CTR) and the isolation voltage. Darlington optocouplers (left) offer a high CTR, while phototransistor optocouplers enable short switching times.

-

The lifespan of a capacitor depends on the maximum allowable operating temperature, the ambient temperature, the ripple current, and the applied voltage. The simplified formulas omit the influence of current and voltage. In RedExpert, the lifespan can be calculated in detail for your application.

-

For the mechanical mounting of printed circuit boards during the assembly of power supplies, various versions of SMT spacers are available. The range includes versions with internal and external threads, angled and straight, reverse and with through-hole, as well as automotive types.

-

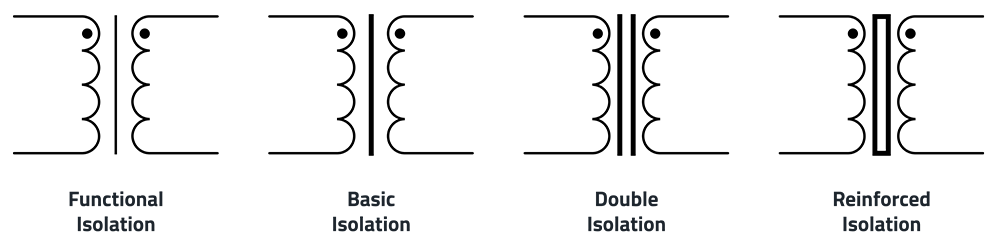

In offline transformers for power supplies, there are different classes of insulation: - Functional insulation does not provide protection but avoids ground loops and short circuits. - Basic insulation is not considered safe on its own but offers a protective layer and functional insulation. - Double insulation is considered safe and provides functional insulation with two protective layers. - Reinforced insulation is considered safe and offers a protective layer without a single point of failure.

-

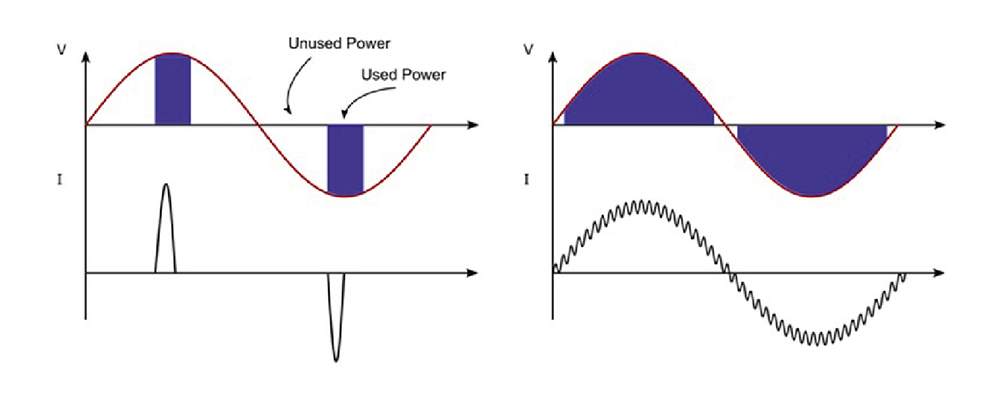

Especially in applications with higher power, a power factor correction (PFC) is needed to reduce reactive power and thus increase efficiency. The standard EN61000-3-2 defines the value of the maximum permissible harmonic currents. This is where power factor correction chokes (PFC Chokes) come into play, ensuring high efficiency with good EMC performance.

-

The REDCUBE terminals provide a powerful connection to the circuit board, for example, as a press-fit version or as a THR or SMT version. The REDCUBE connectors have a special coating for optimal crimping and can be processed with hexagonal standard crimping tools.

-

The REDCUBE terminals provide a powerful connection to the circuit board, particularly in the press-fit version. The press-fit process ensures a homogeneous material transition between the pin and the coating of the insertion hole in the board, which is also referred to as cold welding. A current-carrying capacity of up to 500 A and a pull-out force of 10 kg/pin demonstrate the performance of the REDCUBE terminals.