| General Information | |

|---|---|

| Operating Temperature | -55 °C up to +125 °C |

| Washable | Yes |

| Ingress Protection Code | None |

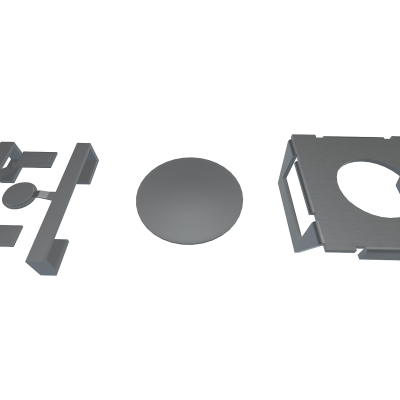

| Material Properties | |

|---|---|

| Actuator Material | PA9T |

| Actuator Flammability Rating | UL94 V-0 |

| Frame Material | PA9T |

| Frame Flammability Rating | UL94 V-0 |

| Contact Plating | Silver |

| Terminal Plating | Silver |

| Electrical Properties | |

|---|---|

| IR | 50 mA |

| VR | 32 V (DC) |

| Contact Resistance Initial | 100 mΩ |

| RISO | 1000 MΩ |

| Withstanding Voltage | 250 V (AC) |

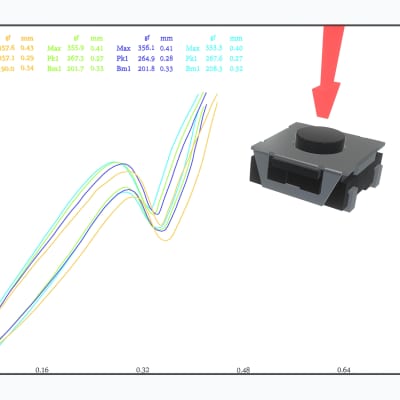

| Mechanical Properties | |

|---|---|

| Operation Force | 200 g; 300 g; 400 g |

| Electrical Life | 100000 Cycles; 150000 Cycles; 200000 Cycles |

| Packaging Properties | |

|---|---|

| Packaging | Tape and Reel |

Application Notes

Products

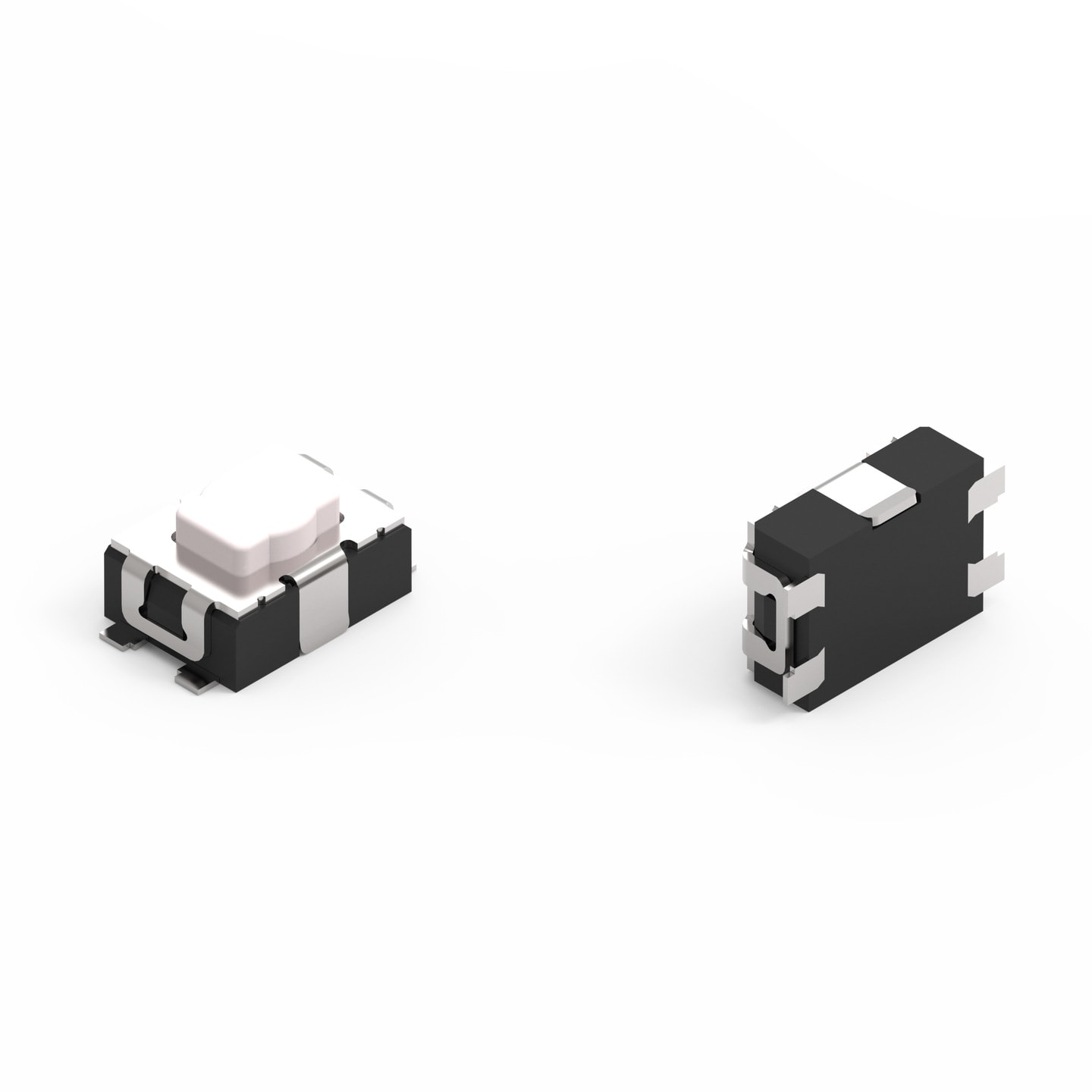

| Order Code | Datasheet | Downloads | Status | H (mm) | Operation Force (g) | Electrical Life (Cycles) | Actuator Color | Samples | |

|---|---|---|---|---|---|---|---|---|---|

| 435431019840 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 1.9 | 400 | 100000 | Salmon | |

| 435441019830 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 1.9 | 300 | 150000 | White | |

| 435451019820 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 1.9 | 200 | 200000 | Black |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | H (mm) | Operation Force (g) | Electrical Life (Cycles) | Actuator Color | Samples |

|---|

#TimetoSwitch

Tact Switches

#TimetoSwitch

Tact Switches

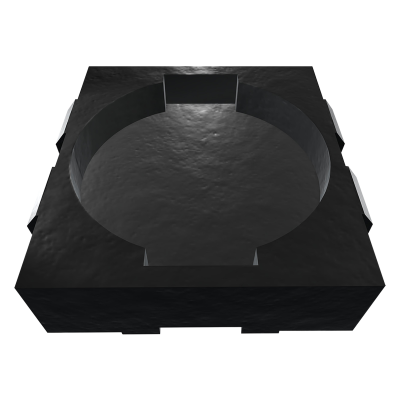

The Tact Switches from Würth Elektronik are characterized by performance stability and long lifetime. All metal elements are corrosion resistant proven by a 48 hours salt spray test. Polyimide tape or silicone rubber protect the switch even in tough environments. The switch range includes various high quality solutions like dip, rotary, detector, micro, slide, rocker switches and encoder. Available from stock. Samples free of charge.

Product Benefits:

- IP67

- Long lifetime

- High durability

- Corrosion resistant metal elements

- Full load life cycle test

- Tight tolerance due to automated production

Characteristics