Applications

- Solderable high current Wire-to-Board & Board-to-Board connections with a focus on automated assembly

- IMS boards or one layer applications

| General Information | |

|---|---|

| Material | Brass |

| Surface | Tin |

| Operating Temperature | -55 °C up to +150 °C |

| Packaging Properties | |

|---|---|

| Packaging | Bulk; Tape and Reel |

Application Notes

Products

| Order Code | Datasheet | Downloads | Status | H (mm) | H1 (mm) | Ti | IR (A) | Ø OD (mm) | Samples | |

|---|---|---|---|---|---|---|---|---|---|---|

| 74660013 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 5.6 | M3 | 85 | 10 | |

| 74660013R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 5.6 | M3 | 85 | 10 | |

| 74660014 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 5.6 | M4 | 85 | 10 | |

| 74660014R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 5.6 | M4 | 85 | 10 | |

| 74660015 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 5.6 | M5 | 85 | 10 | |

| 74660015R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 5.6 | M5 | 85 | 10 | |

| 74660016 | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 5.6 | M6 | 85 | 12 | |

| 74660016R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 5.6 | M6 | 85 | 12 |

| Order Code | Datasheet | |

|---|---|---|

| 74660013 | SPEC |

| 74660013R | SPEC |

| 74660014 | SPEC |

| 74660014R | SPEC |

| 74660015 | SPEC |

| 74660015R | SPEC |

| 74660016 | SPEC |

| 74660016R | SPEC |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | H (mm) | H1 (mm) | Ti | IR (A) | Ø OD (mm) | Samples |

|---|

Applications, Characteristics & Design

Applications

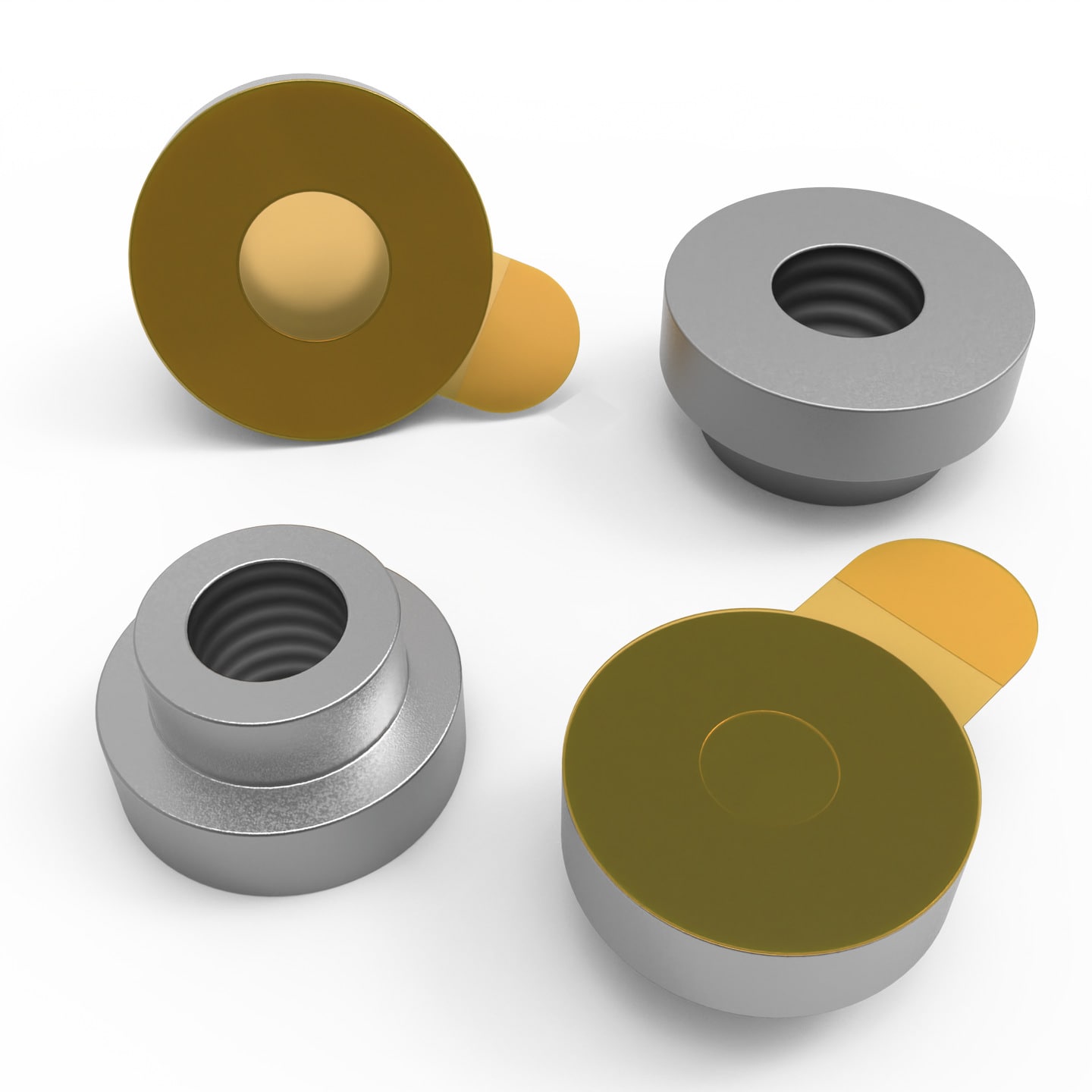

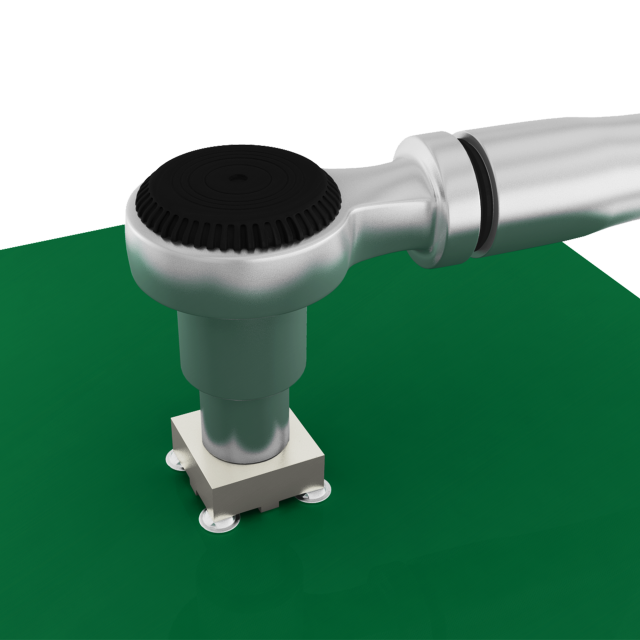

REDCUBE SMD and THR are the result of the growing demand in electronic market: high current technology in combination with fully automated, timesaving processing.

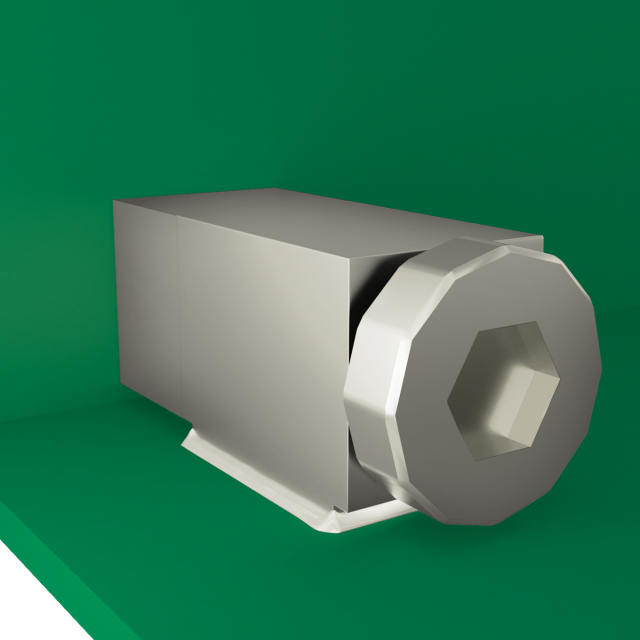

- High current Wire-to-Board & Board-to-Board connections

- Angled assembling of cable, PCB or housing

Impressive Characteristics

A large connecting area of REDCUBE SMD achieves a low contact resistance and best holding forces. The small size of REDCUBE SMD allows a high packing density without critical heat development on the PCB.

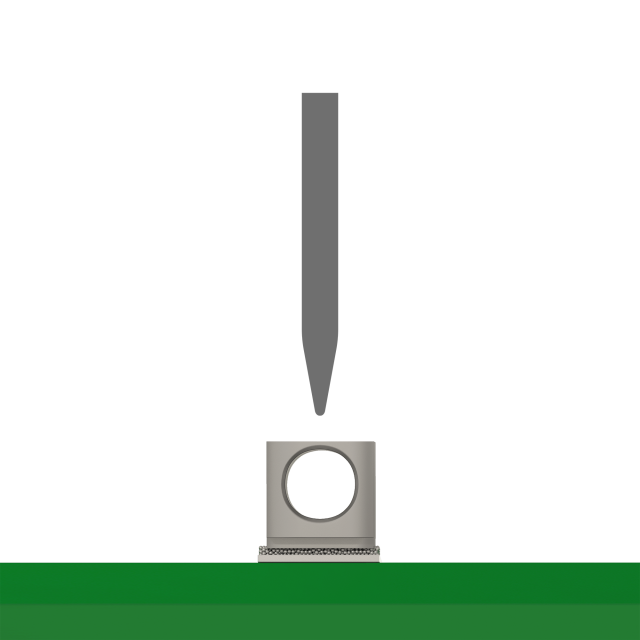

- Simple and fast automated assembly

- High packing density

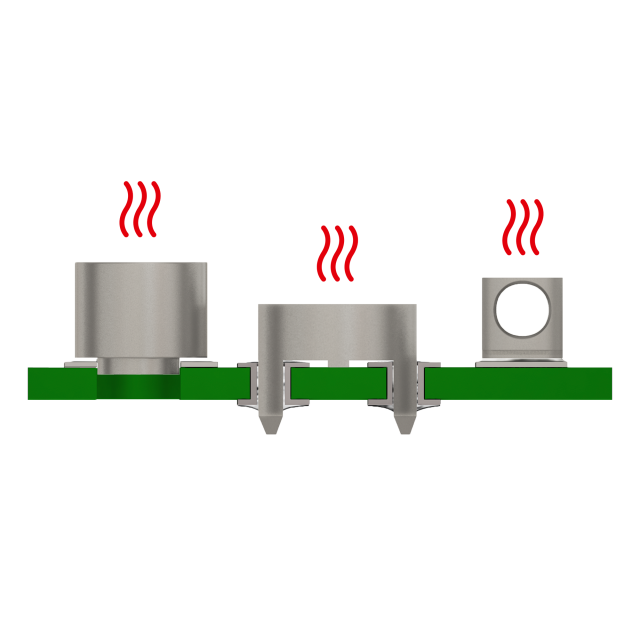

- Efficient and timesaving soldering process

- Angled assembling of cable, PCB or housing

- Tape & Reel

Special Design

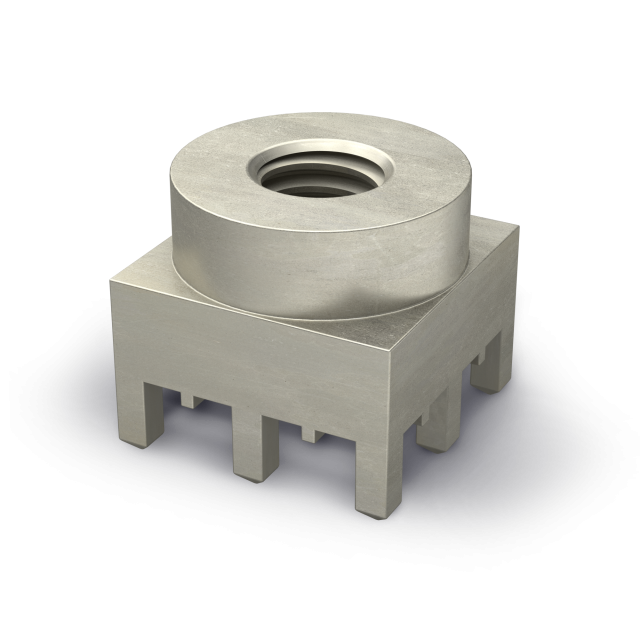

REDCUBE THR have a special design for best soldering results. Milling from solid material the torques are significant better compared to stamped contacts. REDCUBE THR have the highest ampacity of fully automatically processed high-current components.

- Optimal current distribution in multilayer applications

- Fully automated reflow soldering

- High mechanical stability

- Low profile

- Tape & Reel

- Low heat development

Videos

Würth Elektronik Webinar: REDCUBE - Everything about high currents on the printed circuit board

Videos

Würth Elektronik Webinar: REDCUBE HighPower Terminals for ampacity of 50-500 A