| Size | Series Datasheet | Dimensions | L (mm) | W (mm) | H (mm) | Material | Mount | ||

|---|---|---|---|---|---|---|---|---|---|

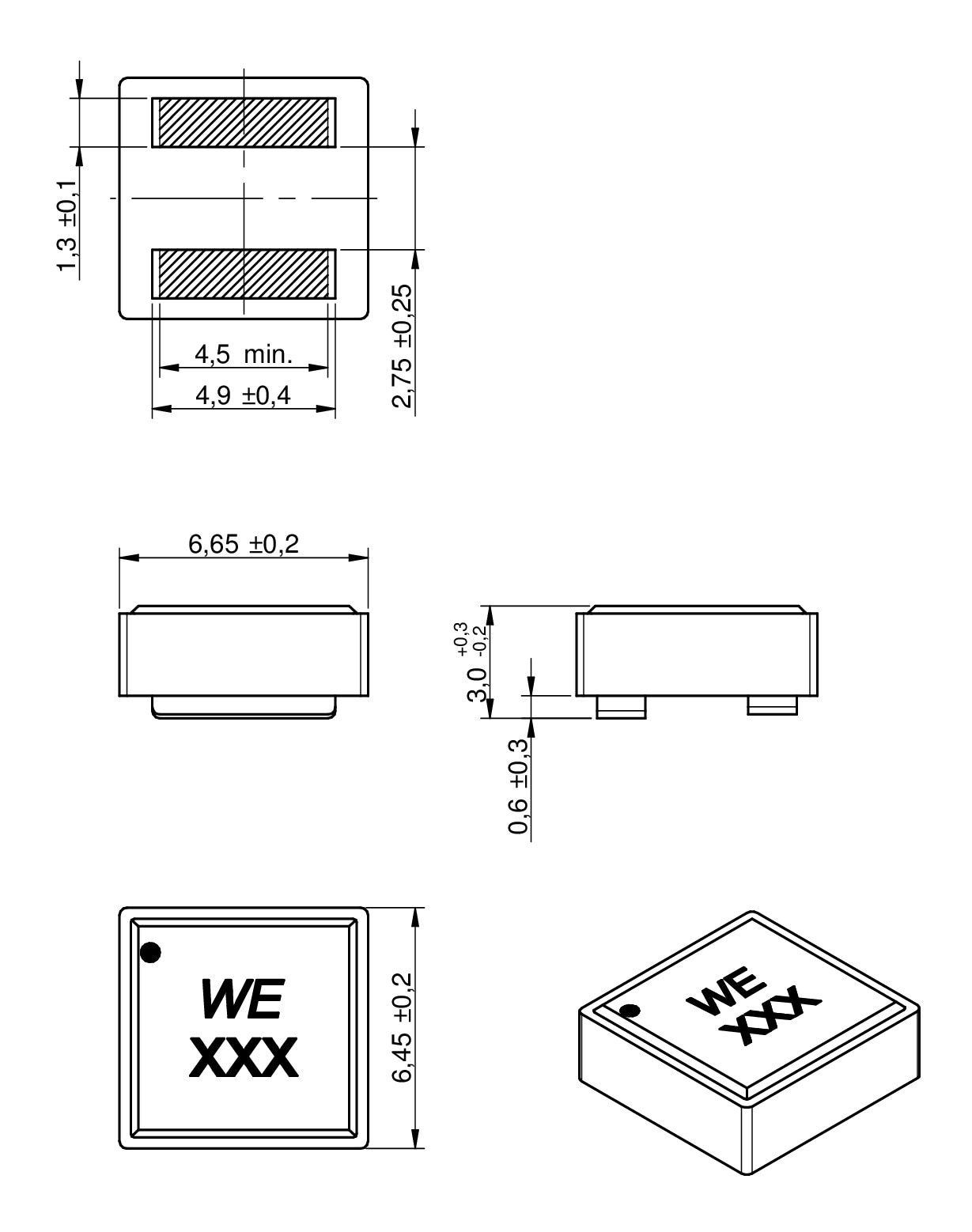

| 6030 | SPEC | 6.65 | 6.45 | 3.3 | Hyperflux | SMT | |||

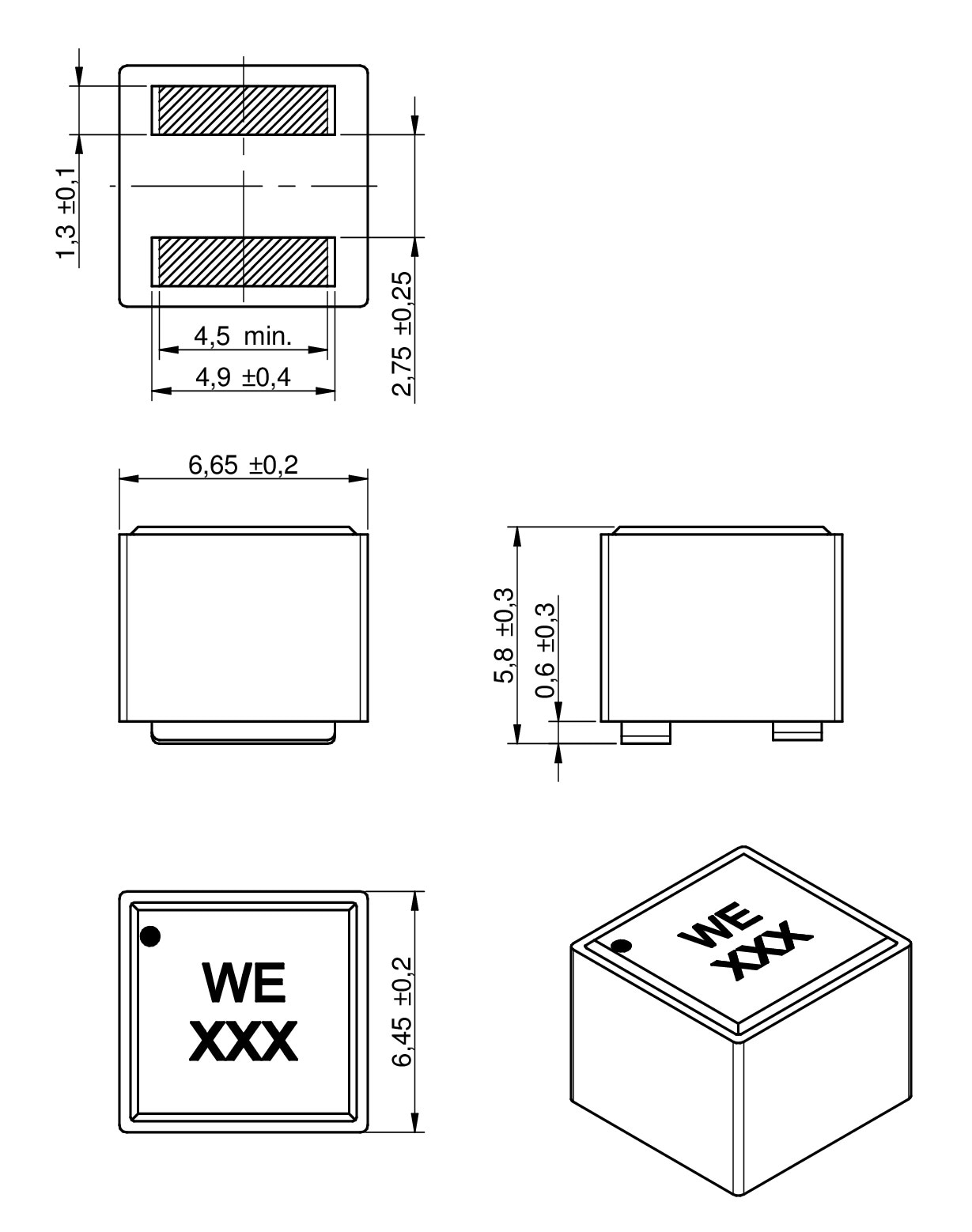

| 6060 | SPEC | 6.65 | 6.45 | 6.1 | Hyperflux | SMT | |||

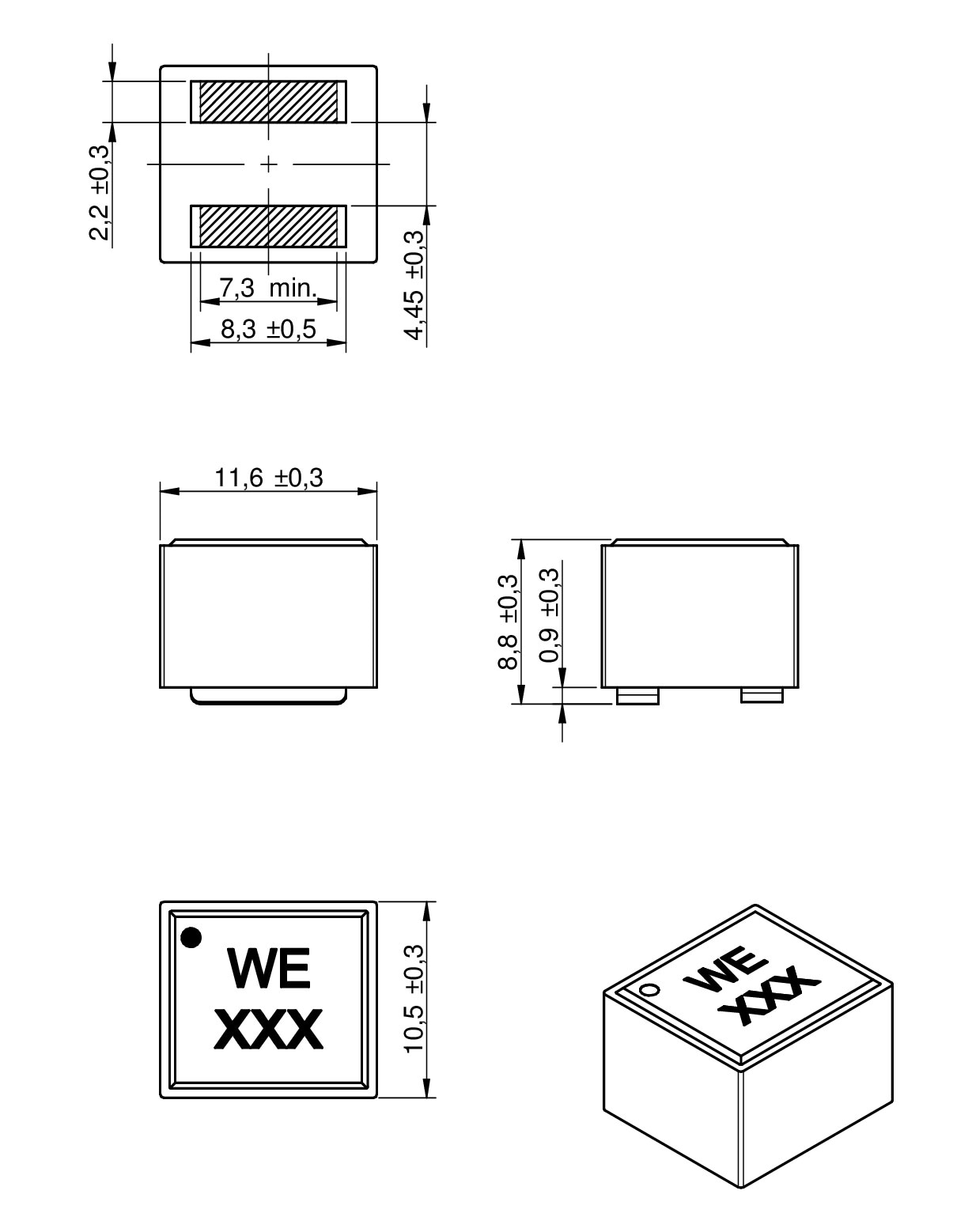

| EXT. | 8080 | SPEC | 8.8 | 8.3 | 8 | Hyperflux | SMT | ||

| 1090 | SPEC | 11.6 | 10.5 | 9.1 | Hyperflux | SMT | |||

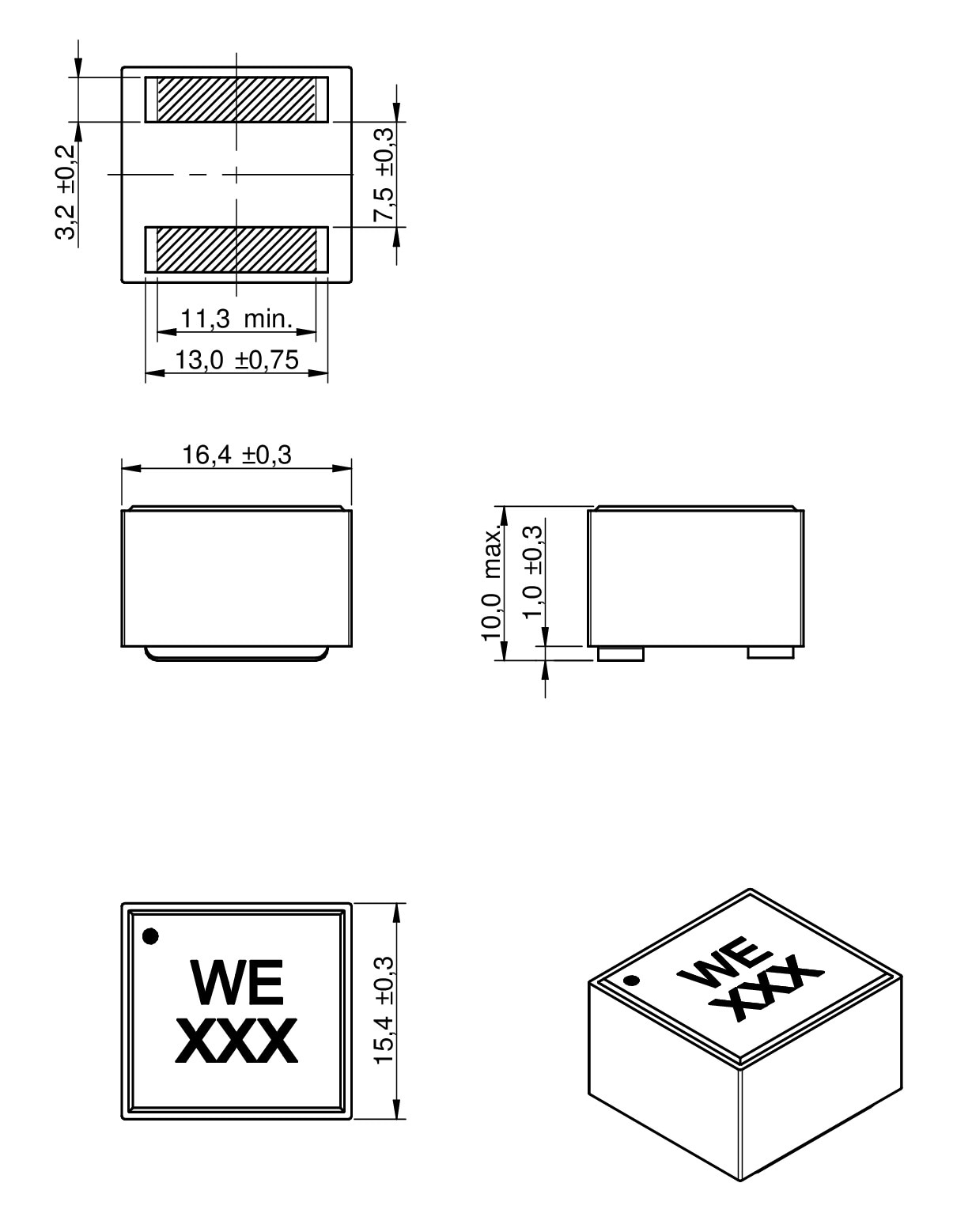

| 1510 | SPEC | 16.4 | 15.4 | 10 | Hyperflux | SMT |

LTSpice files

Characteristics

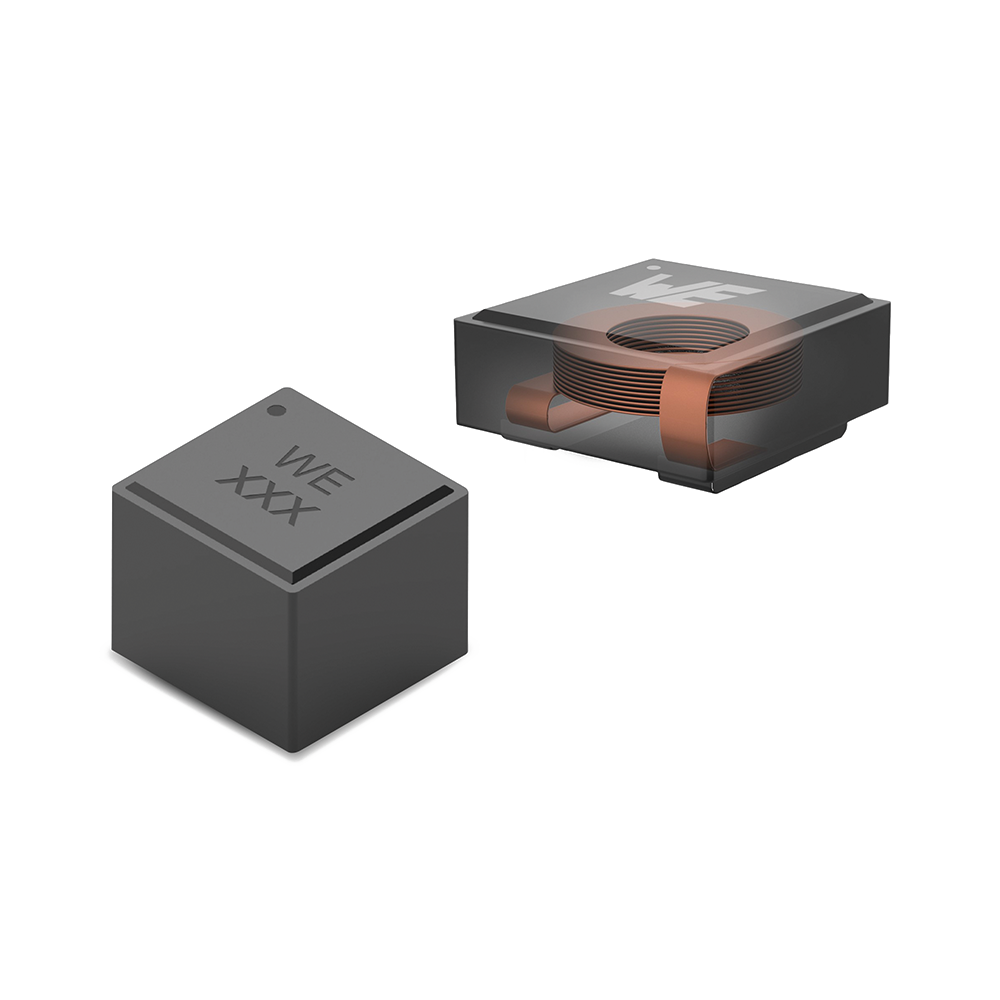

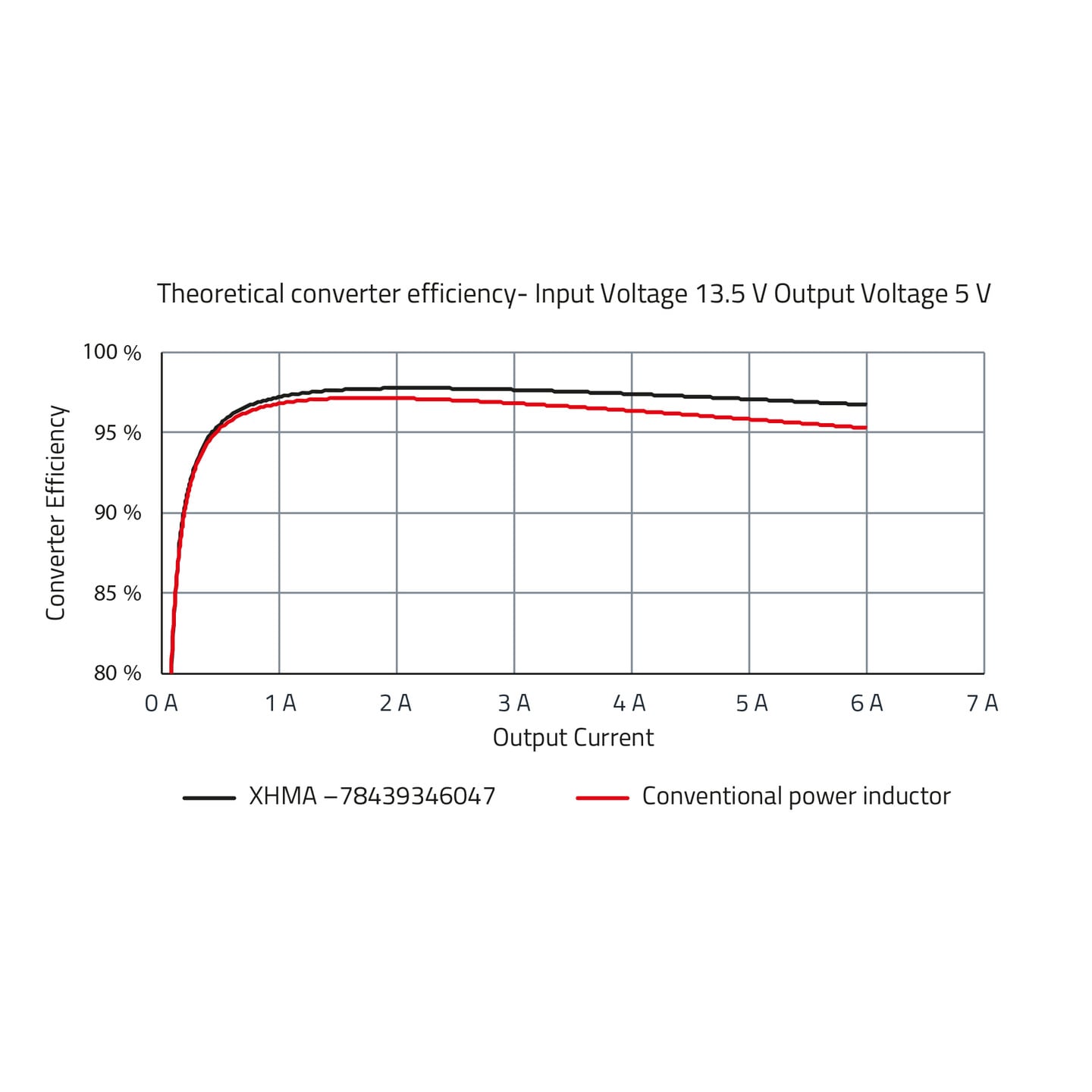

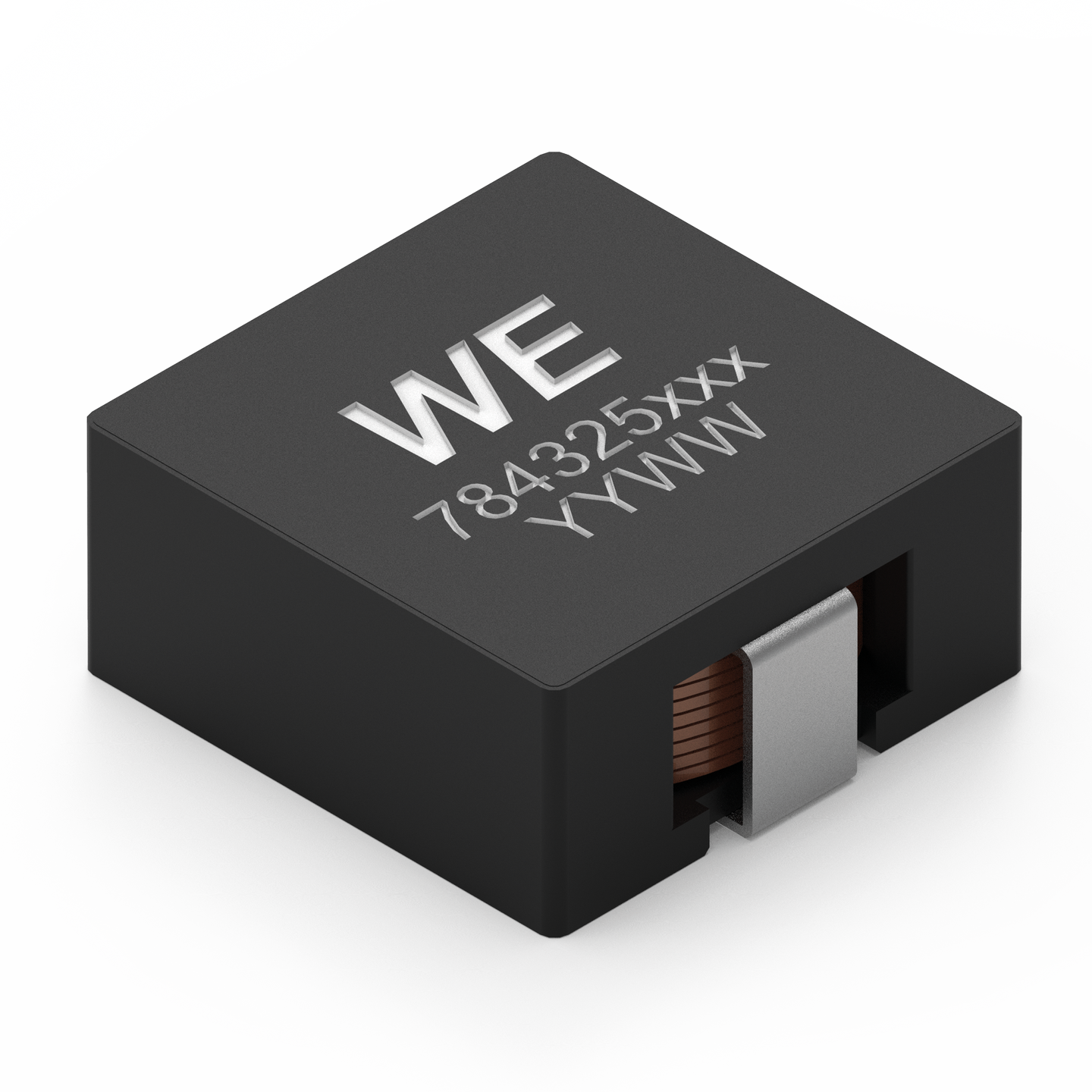

- Flat wire coil for low copper losses

- Composite core material allows high saturation currents

- Compact design

- Magnetically shielded

- High current capability and handles high transient current spikes

- Low leakage flux noise

- Operating temperature: -40°C up to +125°C

- AEC-Q200

- Automotive approved

Applications

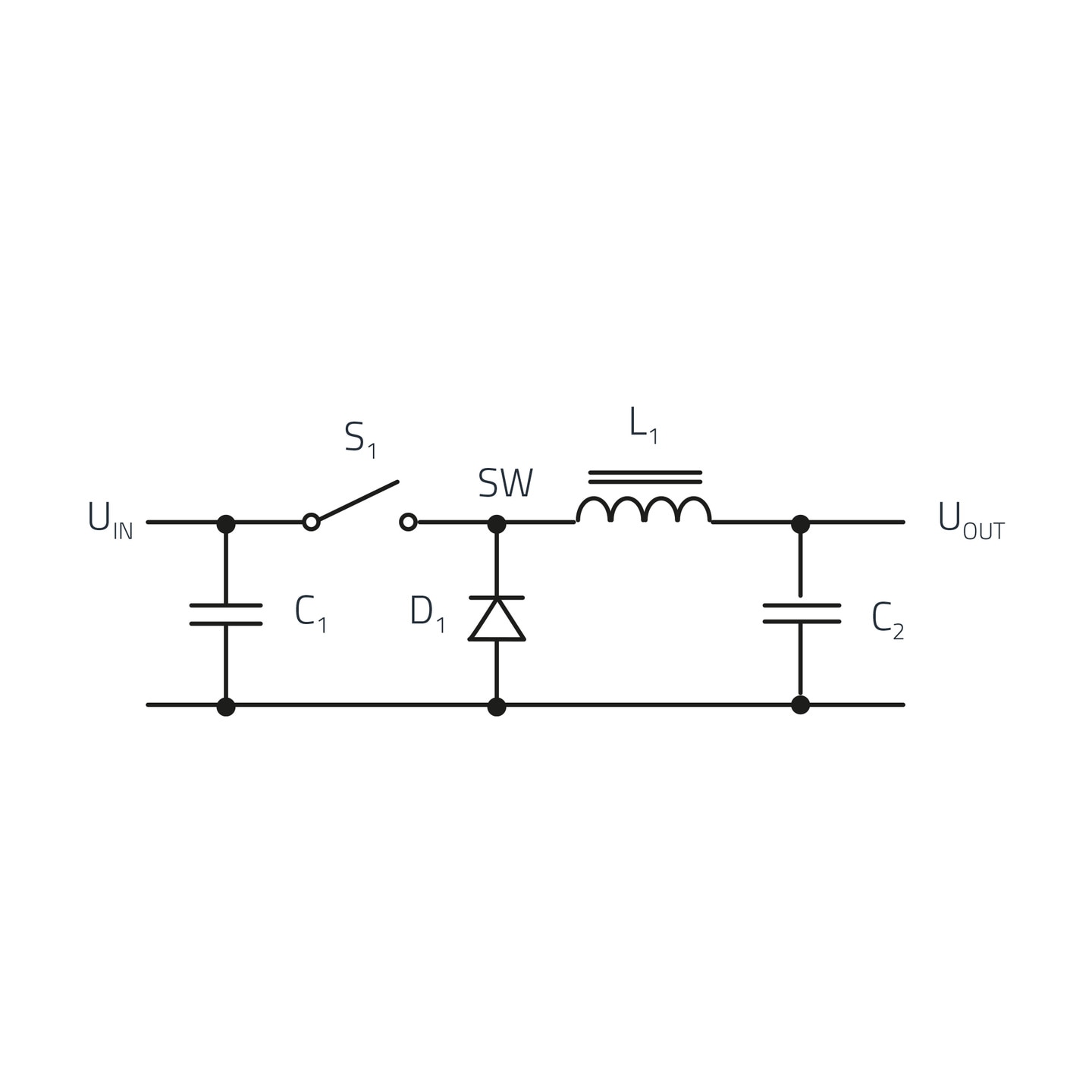

- DC/DC-converter for high current power supplies

- DC/DC-converter for Field Programmable Gate Array (FPGA)

- Power supplies for mobile devices

- POL-converters

- Mainboards/graphic cards

- Battery powered devices

- Filter

Products

All

6030

6060

8080

1090

1510

| Order Code | Datasheet | Downloads | Status | L (µH) | Tol. L | IRP,40K (A) | IR,40K (A) | ISAT,30% (A) | fres (MHz) | ISAT,10% (A) | Mount | RDC typ. (mΩ) | Material | Design Kit | Samples |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 784393440018 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 0.18 | ±20% | 35.65 | 20 | 50.6 | 169 | 24.9 | SMT | 1.32 | Hyperflux | 7843931 | |

| 784393440033 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 0.33 | ±20% | 27.35 | 16.5 | 42.9 | 113 | 20 | SMT | 2.1 | Hyperflux | 7843931 | |

| 784393440056 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 0.56 | ±20% | 22.75 | 16 | 30.8 | 77 | 14.5 | SMT | 2.9 | Hyperflux | 7843931 | |

| 78439344010 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 1 | ±20% | 15.75 | 12 | 24.95 | 59 | 11 | SMT | 5.5 | Hyperflux | 7843931 | |

| 78439358010 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 1 | ±20% | 30.25 | 17 | 38.15 | 53 | 18.15 | SMT | 2.1 | Hyperflux | 7843931 | |

| 78439344012 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 1.2 | ±20% | 14.45 | 10.3 | 21.6 | 53 | 7.7 | SMT | 6.4 | Hyperflux | 7843931 | |

| 78439369022 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 2.2 | ±20% | 32.05 | 16 | 32.1 | 28 | 15.65 | SMT | 2.2 | Hyperflux | 7843932 | |

| 78439344022 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 2.2 | ±20% | 10.85 | 8 | 16.25 | 37 | 7.5 | SMT | 10.5 | Hyperflux | 7843931 | |

| 78439358022 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 2.2 | ±20% | 21.85 | 13 | 26.45 | 33 | 12.55 | SMT | 3.7 | Hyperflux | 7843931 | |

| 78439369033 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 3.3 | ±20% | 24.95 | 15 | 34 | 23 | 15.6 | SMT | 3.4 | Hyperflux | 7843932 | |

| 78439344033 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 3.3 | ±20% | 7.65 | 6 | 14.5 | 31 | 6.7 | SMT | 19.2 | Hyperflux | 7843931 | |

| 78439369047 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 4.7 | ±20% | 20 | 13.5 | 28.05 | 21 | 13.6 | SMT | 5 | Hyperflux | 7843932 | |

| 78439370047 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 4.7 | ±20% | 29.37 | 17 | 47.4 | 16 | 20.9 | SMT | 3.1 | Hyperflux | 7843932 | |

| 78439344047 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 4.7 | ±20% | 5.8 | 4.7 | 10.5 | 28 | 3.7 | SMT | 31 | Hyperflux | 7843931 | |

| 78439346047 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 4.7 | ±20% | 9.6 | 7.4 | 13 | 28 | 6.5 | SMT | 13 | Hyperflux | 7843931 | |

| 78439358047 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 4.7 | ±20% | 13.35 | 9.5 | 16.65 | 22 | 7.5 | SMT | 8.65 | Hyperflux | 7843931 | |

| 78439369056 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 5.6 | ±20% | 18.15 | 11.5 | 24.45 | 18 | 11.1 | SMT | 5.9 | Hyperflux | 7843932 | |

| 78439346056 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 5.6 | ±20% | 8.9 | 6.9 | 12.1 | 25 | 5.8 | SMT | 15 | Hyperflux | 7843931 | |

| 78439369068 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 6.8 | ±20% | 16.3 | 10.5 | 23.25 | 16 | 10.7 | SMT | 7.16 | Hyperflux | 7843932 | |

| 78439370068 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 6.8 | ±20% | 25.3 | 15 | 40.05 | 14 | 17.8 | SMT | 4.1 | Hyperflux | 7843932 | |

| 78439346068 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 6.8 | ±20% | 8.1 | 6.5 | 11.3 | 22 | 5.65 | SMT | 17.6 | Hyperflux | 7843931 | |

| 78439358068 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 6.8 | ±20% | 10.55 | 7.2 | 17.6 | 22 | 8.5 | SMT | 13 | Hyperflux | 7843931 | |

| 78439369082 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 8.2 | ±20% | 13.4 | 9.8 | 20.45 | 16 | 9.4 | SMT | 10 | Hyperflux | 7843932 | |

| 78439370082 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 8.2 | ±20% | 21.35 | 13 | 36.4 | 11 | 15 | SMT | 5.5 | Hyperflux | 7843932 | |

| 78439346082 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 8.2 | ±20% | 6.95 | 5.3 | 9.3 | 19 | 4.6 | SMT | 23 | Hyperflux | 7843931 | |

| 78439369100 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 10 | ±20% | 12.7 | 9.4 | 20.3 | 14 | 9.2 | SMT | 11 | Hyperflux | 7843932 | |

| 78439370100 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 10 | ±20% | 19.6 | 11.5 | 31.2 | 9 | 12.9 | SMT | 6.4 | Hyperflux | 7843932 | |

| 78439346100 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 10 | ±20% | 6.4 | 5 | 9.7 | 18 | 5.05 | SMT | 26.5 | Hyperflux | 7843931 | |

| 78439358100 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 10 | ±20% | 8.5 | 5.8 | 13.5 | 17 | 6.3 | SMT | 19 | Hyperflux | 7843931 | |

| 78439369150 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 15 | ±20% | 10.75 | 8.3 | 16.95 | 11 | 7.2 | SMT | 14.8 | Hyperflux | 7843932 | |

| 78439370150 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 15 | ±20% | 14.7 | 10 | 26.1 | 8 | 10.25 | SMT | 10.5 | Hyperflux | 7843932 | |

| 78439346150 | SPEC | 8 files | Active i| Production is active. Expected lifetime: >10 years. | 15 | ±20% | 4.9 | 4.2 | 7.4 | 14 | 3.65 | SMT | 42 | Hyperflux | 7843931 | |

| 78439358150 | SPEC | 9 files | New i| Product is new in our portfolio and production is active. Expected lifetime: >10 years. | 15 | ±20% | 7.25 | 5.6 | 10.7 | 12 | 5.6 | SMT | 25 | Hyperflux | 7843931 | |

| 78439370220 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 22 | ±20% | 13.35 | 8 | 22.35 | 7 | 9.1 | SMT | 12.5 | Hyperflux | 7843932 | |

| 78439370330 | SPEC | 9 files | Active i| Production is active. Expected lifetime: >10 years. | 33 | ±20% | 10.8 | 8.5 | 18.15 | 5 | 6.8 | SMT | 18 | Hyperflux | 7843932 |

| Order Code | Datasheet |

|---|---|

| 784393440018 | SPEC |

| 784393440033 | SPEC |

| 784393440056 | SPEC |

| 78439344010 | SPEC |

| 78439358010 | SPEC |

| 78439344012 | SPEC |

| 78439369022 | SPEC |

| 78439344022 | SPEC |

| 78439358022 | SPEC |

| 78439369033 | SPEC |

| 78439344033 | SPEC |

| 78439369047 | SPEC |

| 78439370047 | SPEC |

| 78439344047 | SPEC |

| 78439346047 | SPEC |

| 78439358047 | SPEC |

| 78439369056 | SPEC |

| 78439346056 | SPEC |

| 78439369068 | SPEC |

| 78439370068 | SPEC |

| 78439346068 | SPEC |

| 78439358068 | SPEC |

| 78439369082 | SPEC |

| 78439370082 | SPEC |

| 78439346082 | SPEC |

| 78439369100 | SPEC |

| 78439370100 | SPEC |

| 78439346100 | SPEC |

| 78439358100 | SPEC |

| 78439369150 | SPEC |

| 78439370150 | SPEC |

| 78439346150 | SPEC |

| 78439358150 | SPEC |

| 78439370220 | SPEC |

| 78439370330 | SPEC |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | L (µH) | Tol. L | IRP,40K (A) | IR,40K (A) | ISAT,30% (A) | fres (MHz) | ISAT,10% (A) | Mount | RDC typ. (mΩ) | Material | Design Kit | Samples |

|---|

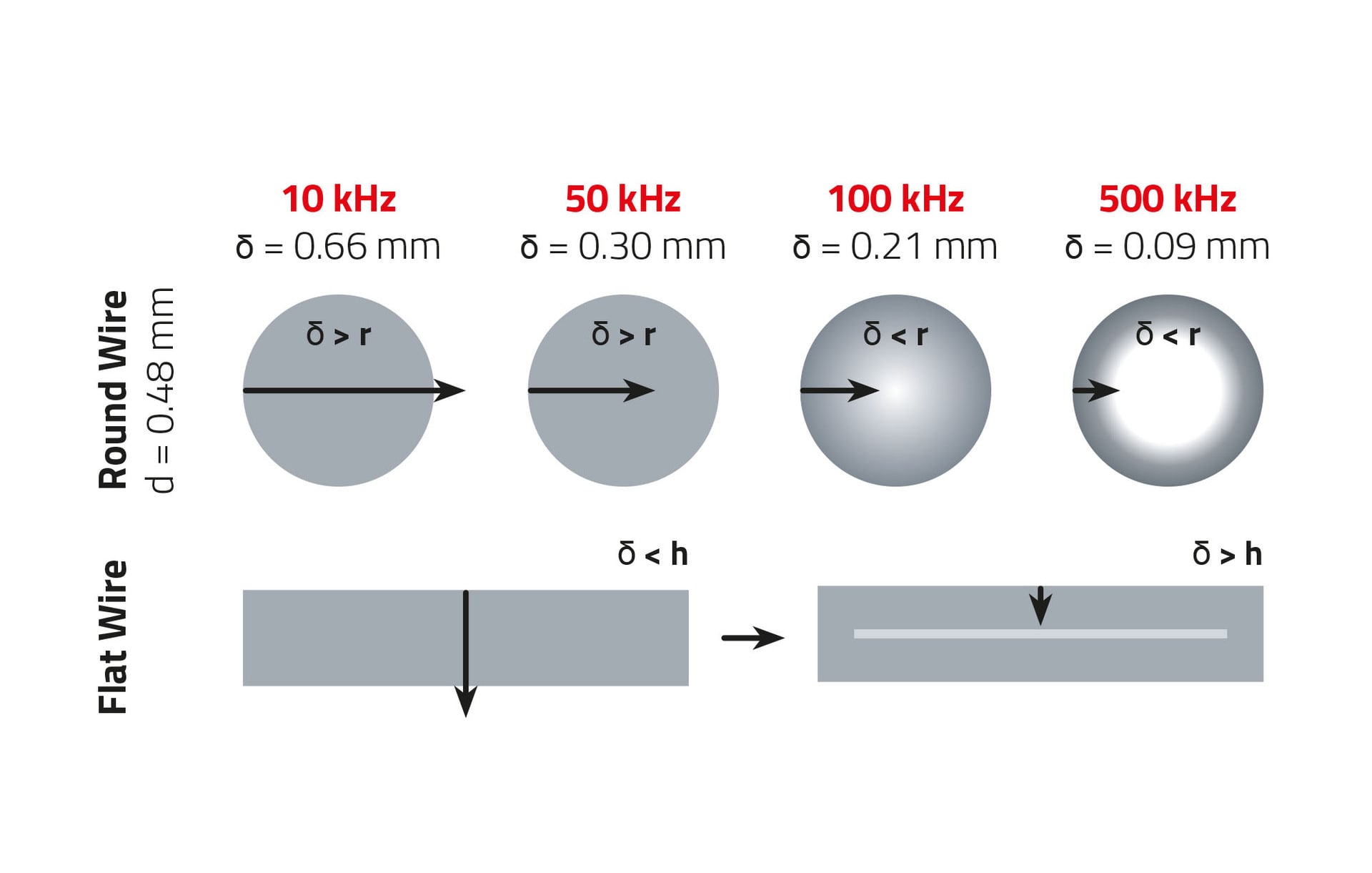

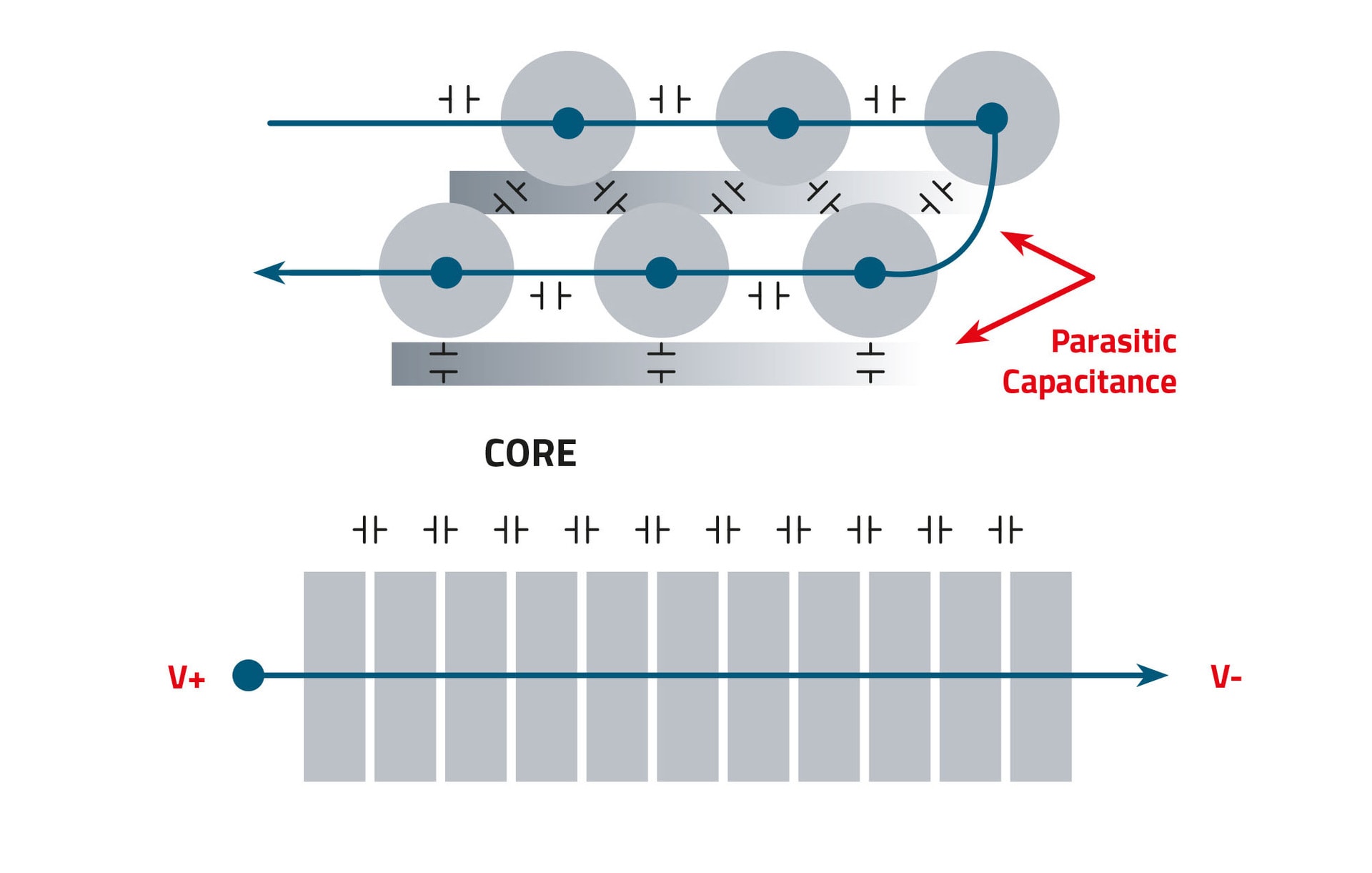

The Implications of the Skin Effect

The AC skin effect reduces the effective cross section area the current can flow. A flat wire has much more surface area with the same cross-sectional area. With more surface area, the impact of the skin effect is reduced.

Assortments

Articles from this product series can be found in the following assortments: