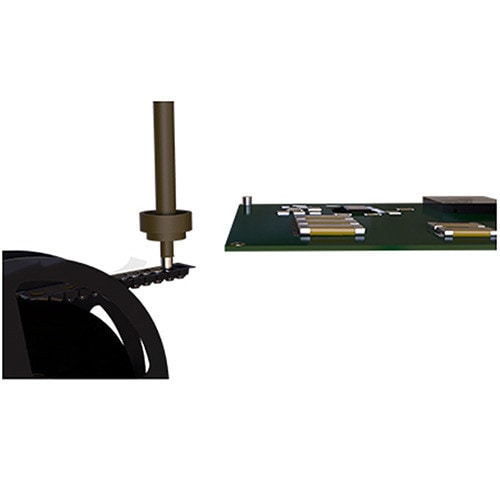

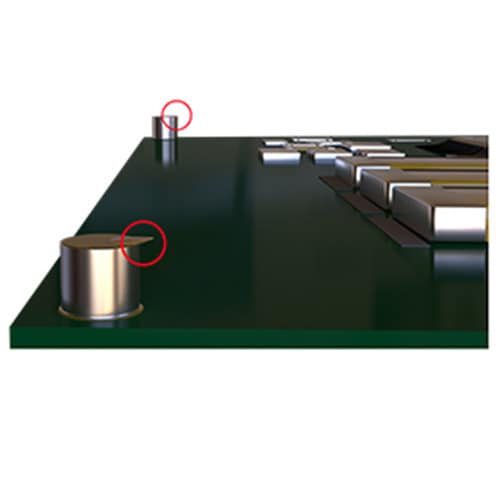

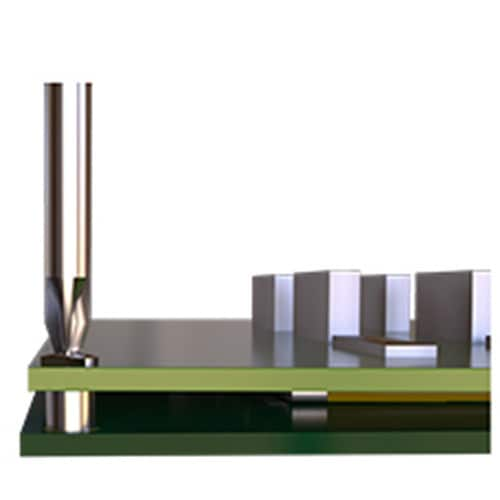

Applications

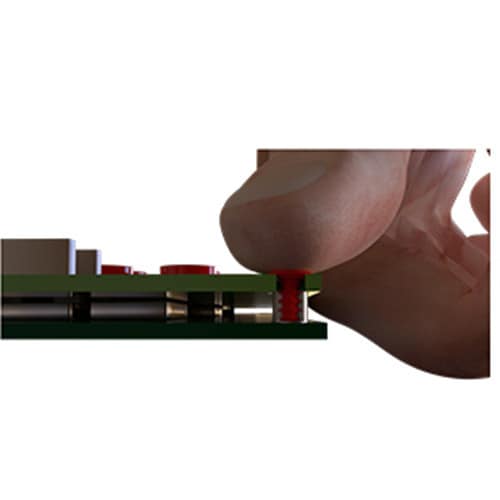

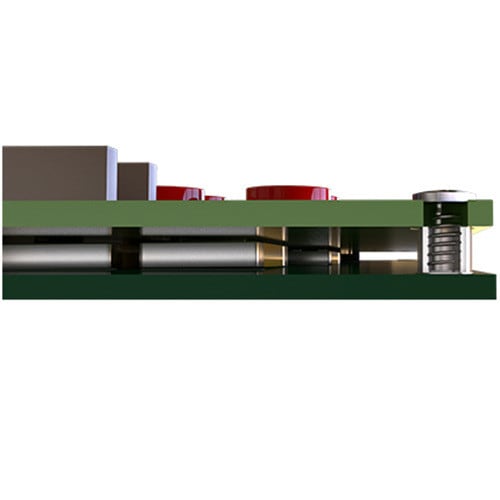

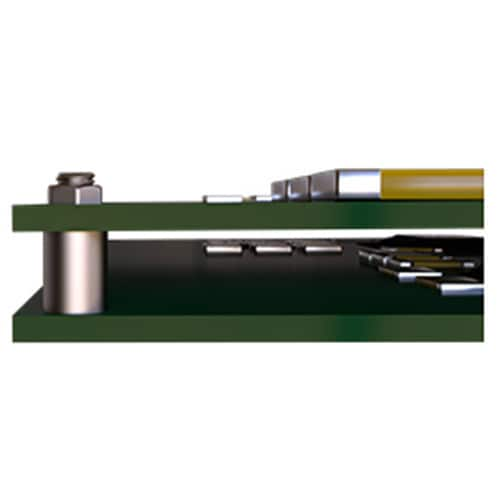

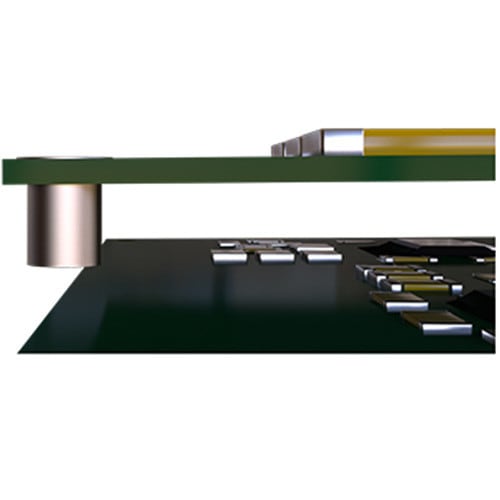

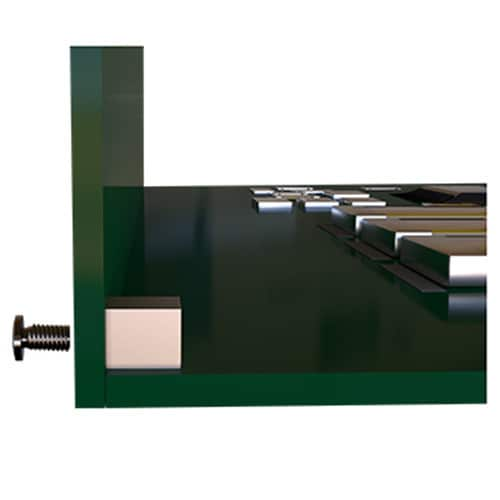

- Assembling of PCBs to housing and to other PCBs

- For distances from 1 to 10 mm

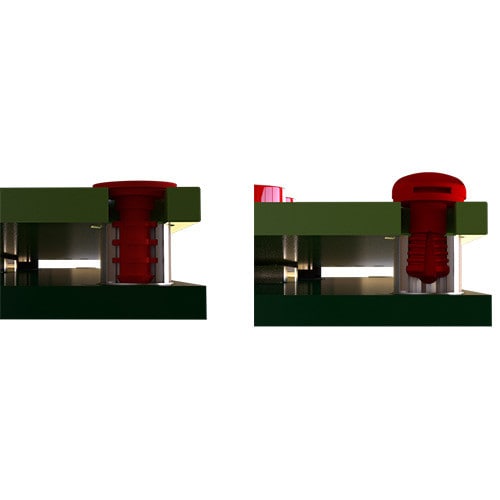

- Fast and precise process

- Strong holding forces torques

- Highest process reliability

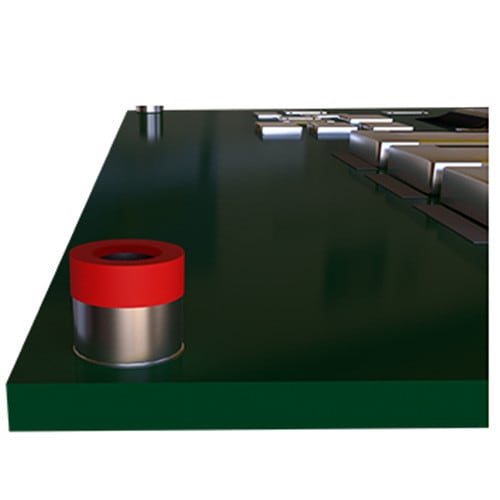

- Instant removable Polyimide Tape

| General Information | |

|---|---|

| Operating Temperature | -55 °C up to +150 °C |

| Material | Steel |

| Surface | Tin |

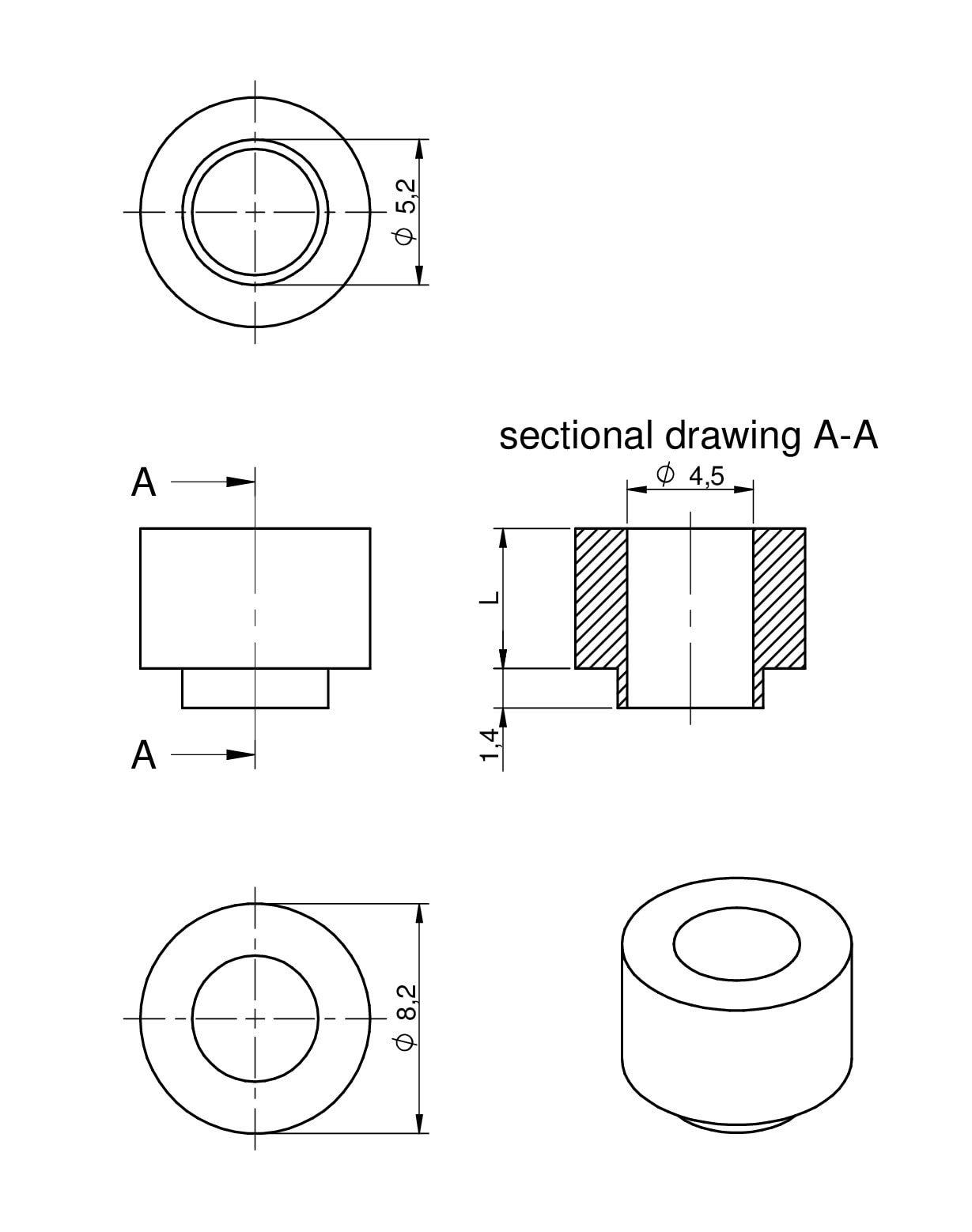

| Ø f | 4.5 mm |

| Solder Cream Thickness | 150 µm |

Products

| Order Code | Datasheet | Downloads | Status | L (mm) | Ø f (mm) | Ø ID (mm) | Ø OD (mm) | Packaging | Qty. | Samples |

|---|---|---|---|---|---|---|---|---|---|---|

| 9774010982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 1 | 4.5 | 5.2 | 8.2 | Tape and Reel | 1500 | |

| 9774020982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 2 | 4.5 | 5.2 | 8.2 | Tape and Reel | 1100 | |

| 9774030982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 3 | 4.5 | 5.2 | 8.2 | Tape and Reel | 900 | |

| 9774040982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 4 | 4.5 | 5.2 | 8.2 | Tape and Reel | 700 | |

| 9774050982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 5 | 4.5 | 5.2 | 8.2 | Tape and Reel | 600 | |

| 9774060982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 6 | 4.5 | 5.2 | 8.2 | Tape and Reel | 500 | |

| 9774070982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 7 | 4.5 | 5.2 | 8.2 | Tape and Reel | 450 | |

| 9774080982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 8 | 4.5 | 5.2 | 8.2 | Tape and Reel | 400 | |

| 9774090982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 9 | 4.5 | 5.2 | 8.2 | Tape and Reel | 350 | |

| 9774100982R | SPEC | 6 files | Active i| Production is active. Expected lifetime: >10 years. | 10 | 4.5 | 5.2 | 8.2 | Tape and Reel | 300 |

| Order Code | Datasheet |

|---|---|

| 9774010982R | SPEC |

| 9774020982R | SPEC |

| 9774030982R | SPEC |

| 9774040982R | SPEC |

| 9774050982R | SPEC |

| 9774060982R | SPEC |

| 9774070982R | SPEC |

| 9774080982R | SPEC |

| 9774090982R | SPEC |

| 9774100982R | SPEC |

| Samples |

|---|

| Order Code | Datasheet | Downloads | Status | L (mm) | Ø f (mm) | Ø ID (mm) | Ø OD (mm) | Packaging | Qty. | Samples |

|---|