Electromagnetic compatibility (abbreviation EMC) refers to the ability of an electronic device or system to function correctly in its electromagnetic environment. The device or system must not introduce any impermissible electromagnetic interference into this environment, which also includes other equipment. The intended operation at the planned place of use under the electromagnetic environmental conditions prevailing there must also be ensured.

When I was a child, electronic devices were a rarity; today, the number is almost unmanageable. At the same time, devices are getting smaller and faster. While there used to be phone booths on almost every corner, smartphones have become an integral part of our everyday lives.

Every electronic device generates an electromagnetic field, which can lead to electromagnetic interference (EMI). This means that we are practically always surrounded by EMI. How this affects a device and other electronic gadgets is where electromagnetic compatibility (EMC) comes into play.

In today's electronic ecosystem, where devices are increasingly interconnected and communication is ubiquitous, EMC ensures that electronic systems can coexist efficiently and without interference. It is therefore about ensuring that one device does not cause unintended failures in other devices and at the same time is not disturbed by other devices. In short, to be electromagnetically compatible, you need to prevent emissions and have a high level of immunity.

Since you cannot see electromagnetic fields, some examples are shown below to make the topic more tangible.

Electromagnetic compatibility can be easily illustrated using the example of an FM radio. Here, the electromagnetic field is used specifically to transmit messages. In Germany and most other countries, this takes place in the frequency range from 87.5 to 108 MHz. If an electronic device in the vicinity generates EMI in the same frequency range, it can interfere with radio transmission. In this case, noise can be heard on the radio or the transmission is interrupted. Typical devices that cause such interference are, for example, poorly suppressed vacuum cleaners, drills or LED lighting drivers.

There is even a trend among winter sports enthusiasts to take more and more electronic devices such as smartphones, smartwatches, action cams and GPS devices with them, including heated socks and gloves. However, in an emergency, EMI can affect the performance of avalanche transceivers and therefore pose a potential risk to safety in the terrain [1].

Another critical point is the influence on devices in medical equipment. With current trends such as high-power fast charging stations and batteries with increasing performance, the challenges for e-mobility are increasing. However, as manufacturers of electric cars are keen to prevent interference between the battery and electrical systems in the car, the batteries are very well shielded. Initial studies have already examined possible interference with pacemakers caused by high-voltage batteries in electric cars and have given the all-clear [2].

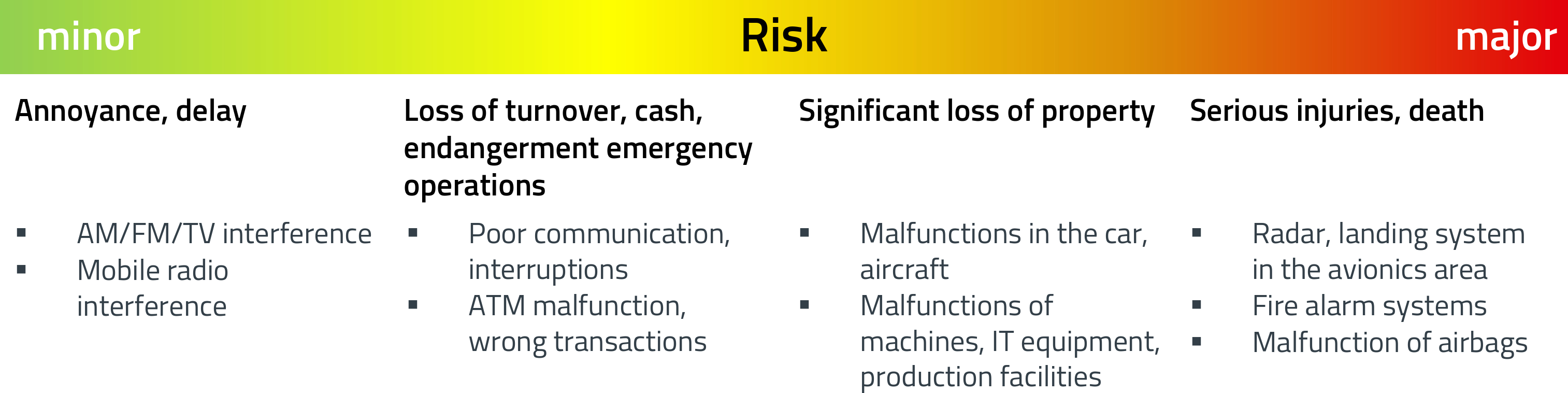

The effects of a device failure can therefore be harmless, but also life-threatening. This is why there are many regulations for EMC in this area to guarantee and ensure the safety of electronic devices. Read more about this in our next blog post "What is EMC? Guidelines and regulations".

[1] https://www.bergundsteigen.com/artikel/stoerquellen-bei-der-lvs-suche/