In electronic systems, voltage regulators are crucial for maintaining a stable output voltage despite variations in input voltage or load conditions. Traditional voltage regulators, such as linear regulators and switching regulators, have been widely used, but they come with certain limitations, especially in high-performance applications. As a special case of the multi-phase voltage regulator, trans-inductor voltage regulators promise higher performance here.

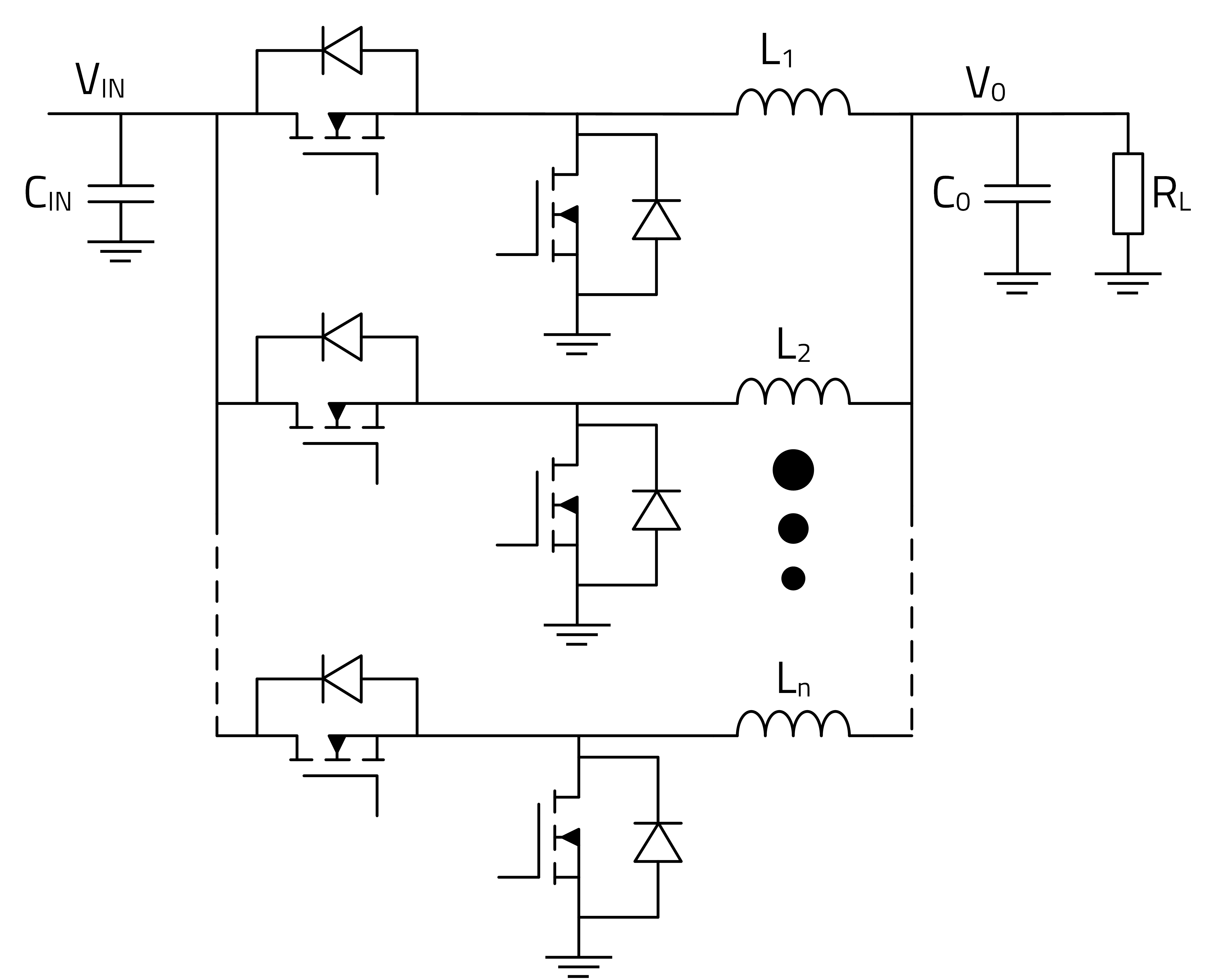

Multi-phase voltage regulators (MVR) are using multiple phases or channels to convert a DC input voltage into a different DC output voltage as you can see in Figure 1. These converters are widely used in applications requiring high power density because they are able to distribute the energy through the different phases of the system, improving the efficiency and the thermal performance compared with a single DC/DC regulator.

Figure 1. DC/DC converter with multi-phase voltage regulator topology.

In a world where every year customers require more and more power in a shorter period, every possible improvement in the performance is a fight won for the designer.

Here a new topology called Trans-Inductor Voltage Regulator (TLVR) comes into play, which offers fast transient response, higher power density and lower solution cost in applications where sudden load changes occur.

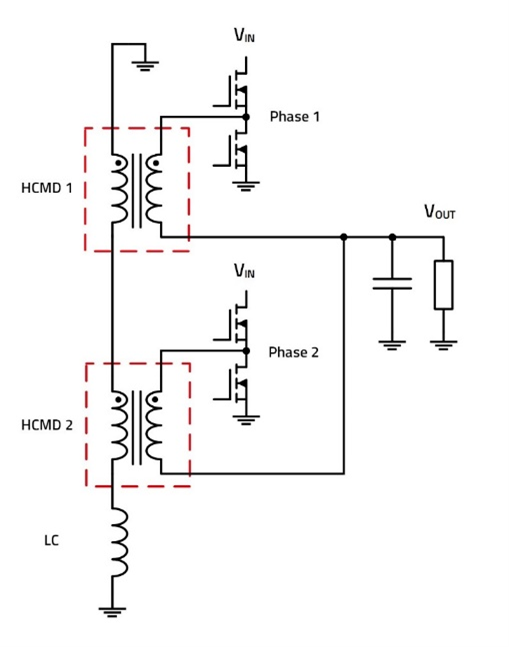

The TLVR topology consists of a primary side where each coupled inductor (WE-HCMD 1, and WE-HCMD 2, to WE-HCMD n) in Figure 2 are connected between the switch node of each phase and the converter output voltage. A secondary loop connected in series with the total number of phases by the secondary coil of the coupled inductors and an additional compensating inductor (LC).

Figure 2. Trans-Inductor Voltage Regulator structure.

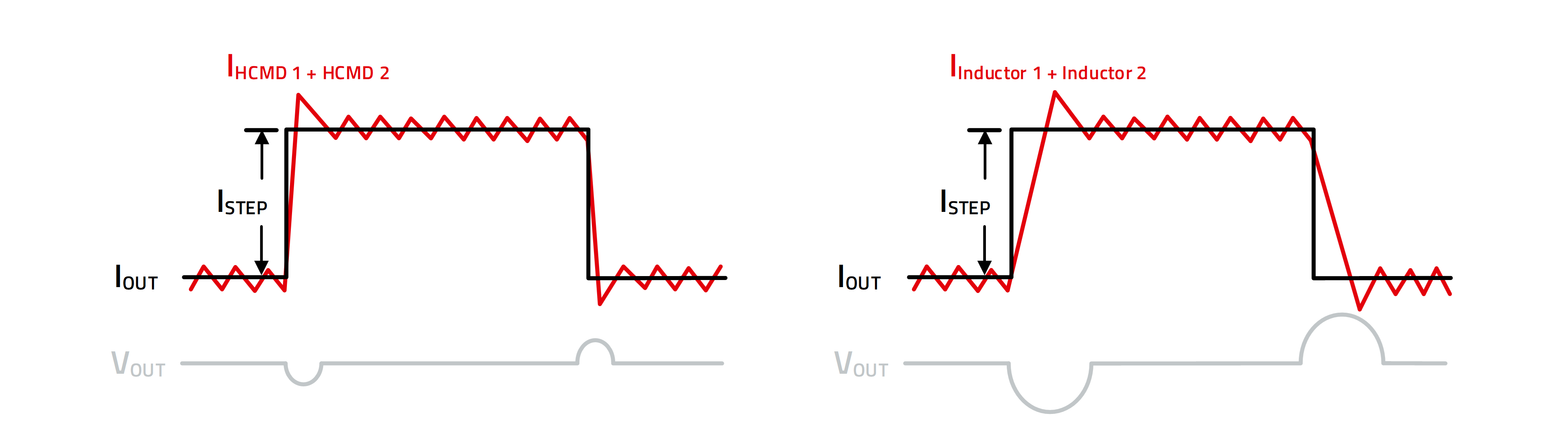

The added secondary winding is the key reason TLVR can achieve high performance in the transient response to a load demand. The secondary loop distributes current dynamically during load transients. The compensating inductor allows for better control of current shared among phases. They sum up to the current used by the load, reducing the peak-to-peak ripple current. This results in a faster transient response and lower voltage drop during load transients compared with a multi-phase DC/DC converter, as shown in Figure 3. This allows for an increased current demand and operating frequency in the application, reducing delays caused by phase interleaving and minimizing voltage overshoot and undershoot during load transients. As a result, voltage regulation is improved and stress on the power components is reduced.

Figure 3. Left: Improved transient response with the TLVR topology. Right: Response of a MV Buck Regulator.

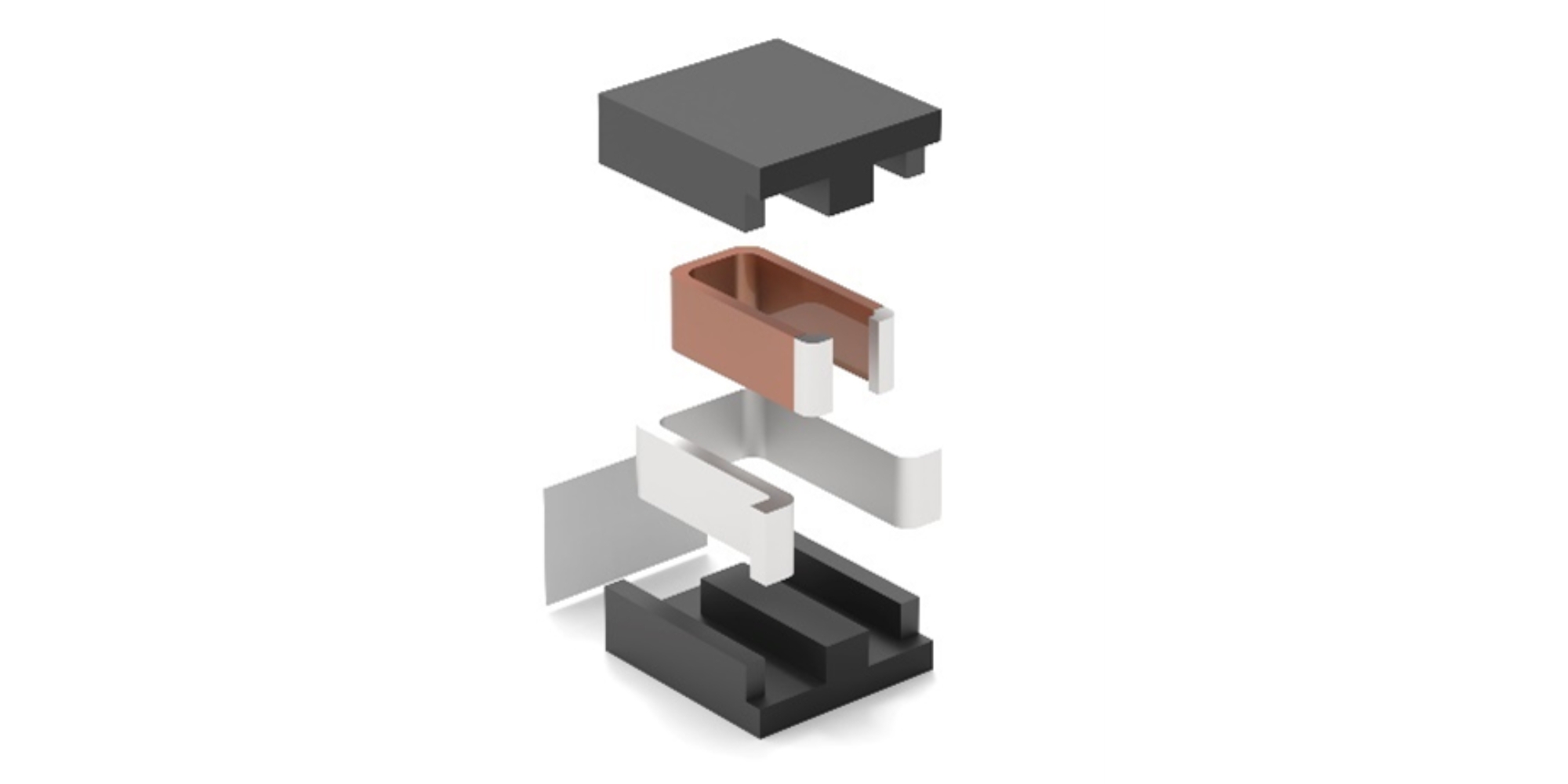

This complex topology requires a certain kind of power inductor specially designed for it. WE-HCMD, with its coupled design, is capable of withstanding significantly high currents while maintaining a stable inductance drop and high efficiency, even when the power demand of the target application is challenging. WE-HCMD achieves this through its internal design, which utilizes two clips to achieve an extremely low RDC and employs a high-permeability core material to increase the inductance value with the shortest possible length of copper.

Figure 4. Structure of the power inductor WE-HCMD from Würth Elektronik.

Using the TLVR topology, the designer can use a larger inductance value and a lower nominal output capacitor for the same application. This results in decreased ripple current, reduced board space, and lower overall design costs compared to a multi-phase DC-DC converter.

TLVR outperforms standard multi-phase voltage regulators in efficiency, transient response, scalability, and component optimization, making it the superior choice for high-performance, high-current applications. While standard regulators remain suitable for less demanding systems, TLVR's advanced capabilities position it as a forward-looking solution for modern power delivery challenges.

[1] https://www.we-online.com/en/components/products/pbs/power_magnetics/shielded_power_inductors/info

[2] https://www.ti.com/lit/ml/slup413/slup413.pdf?ts=1759842843758