Additive color mixing with red, green and blue LEDs, grouped into pixels, opened up new possibilities for displays and lighting designs. When the first modules with integrated circuits (ICs) appeared around ten years ago, the solutions became not only more compact but also more efficient. Würth Elektronik has only been offering ICLEDs since the beginning of 2024, but has set itself the goal of specifically addressing the previous weaknesses of this technology.

Signal control systems, full-color LED matrix displays, audio and gaming devices, ambient lighting systems or displays at charging stations use powerful solutions by using adjacent red, green and blue LEDs as pixels instead of the pixels of an LCD. ICLEDs - also known as addressable, smart or pixel LEDs - are light-emitting diode packages in which an integrated circuit (IC) is built in. This driver uses pulse width modulation (PWM) to enable individual control of the red, green and blue chips in the package and therefore sophisticated and precise lighting solutions with different colors. Because each pixel color can be individually regulated with brightness from 0 to 100 percent and digitally dimmed, more than 16 million different color and brightness values can be generated with the integrated RGB LEDs. And as fewer components such as series resistors are required, display solutions with intelligent LEDs are not only quicker to implement but also more energy-efficient than conventional LEDs. Digital control increases the flexibility of what can be displayed. For example, illuminated traffic signs could display any text or symbols instead of being limited to a few preset circuits.

Anyone entering a market at a later stage must set themselves apart with clear differentiating features. Würth Elektronik therefore not only offers a special service, but also relies on the highest quality standards. With its Horticulture LEDs, the manufacturer attracted attention by offering not only the LEDs themselves, but also solutions for the associated control. The company also has its own research department dedicated to developing light recipes to optimize plant growth. For its ICLEDs, which are available in four designs, Würth Elektronik placed particular emphasis on high-quality processing, such as gold plating for chip LED models and silver plating for PLCC models in order to improve solderability. Comparative measurements with pin-compatible competitor models showed a 40 percent higher illuminance. An annoying problem during assembly has also been tackled: In contrast to comparable solutions previously available on the market, the intelligent LEDs from Würth Elektronik have a moisture sensitivity level of MSL3 - instead of the usual MSL5 or MSL 5a. This means that they can be used in the SMT line for one week. In order to qualify the LEDs for various applications, the manufacturer provides photobiological test reports in accordance with EN 62471:2008 and IEC 62471:2006 for all models in the product group. These are relevant, for example, when the intelligent LEDs are used in toys. Although the product was not developed specifically for the automotive market, Würth Elektronik has also carried out the tests and qualifications methodically in accordance with AEC Q102-003. This provides customers with objectively comparable specifications.

Good workmanship, high performance values and features such as IPx7 protection for some models are strong arguments in favor of components. But the crucial question is their practical effect in the application. This is precisely where Würth Elektronik comes in to open a new chapter in the use of smart LEDs. Smart LEDs offer new possibilities, but the trouble is great if they do not exploit this potential in practice. Color deviations between different production batches in particular are a frequent challenge in ICLED applications. If the control of ICLEDs makes it possible to choose from 16 million color and brightness values, it should also be possible to reliably and reproducibly apply a specific color tone uniformly to a group of LEDs.

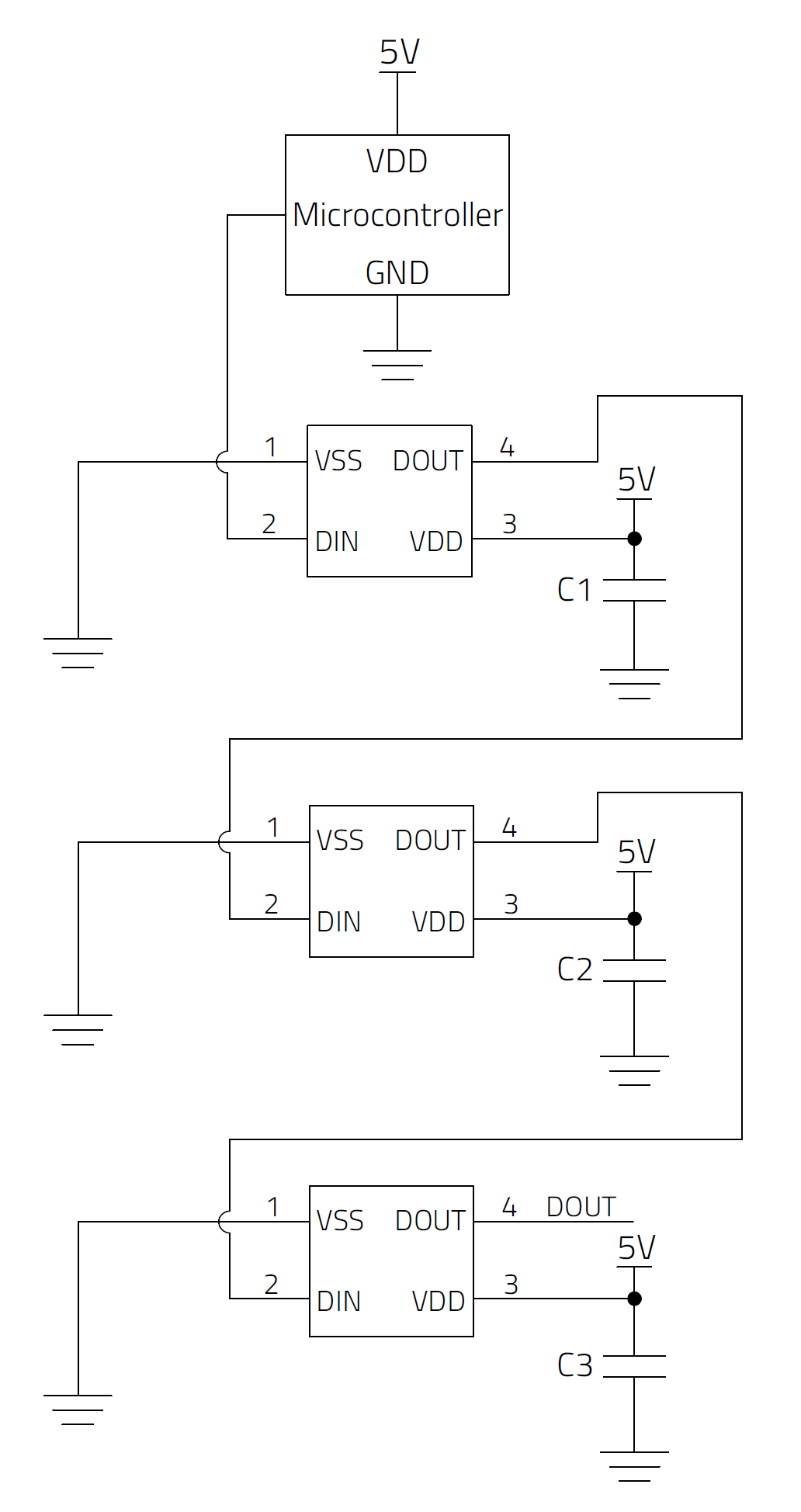

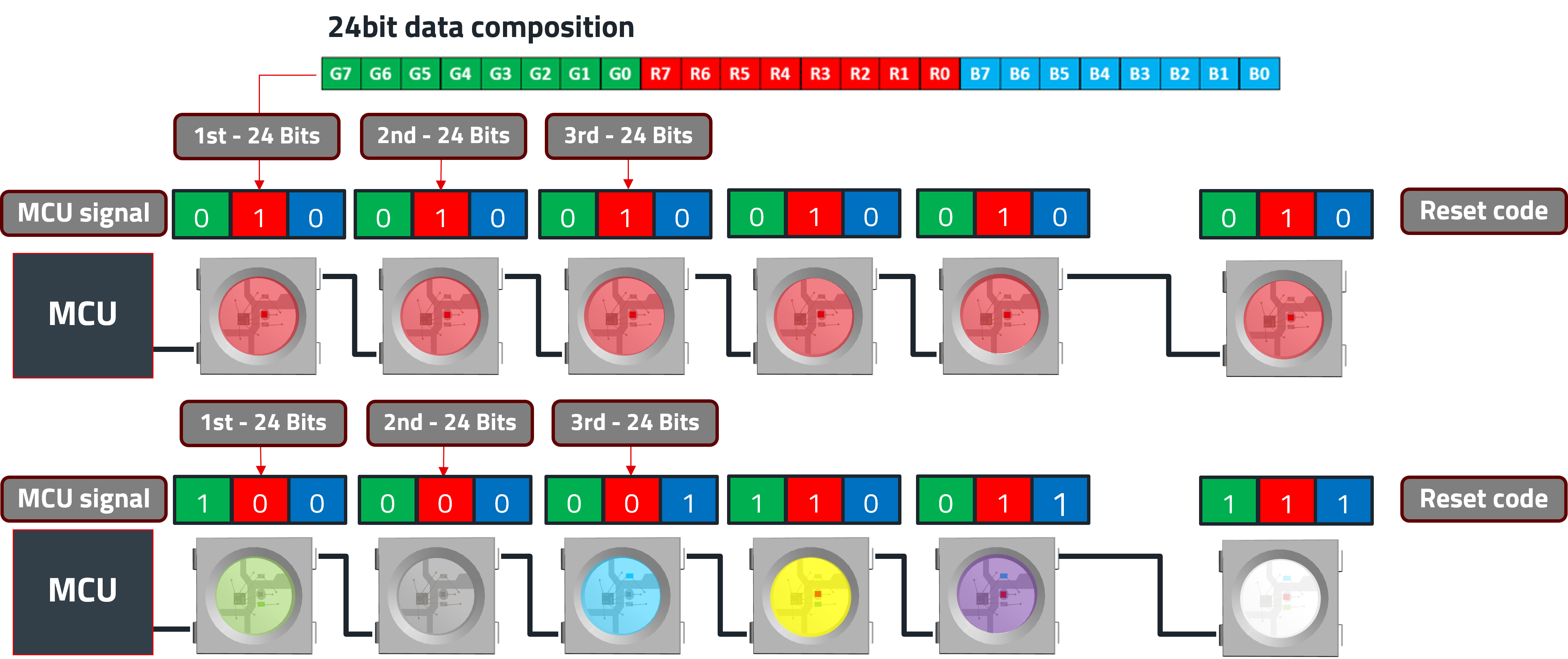

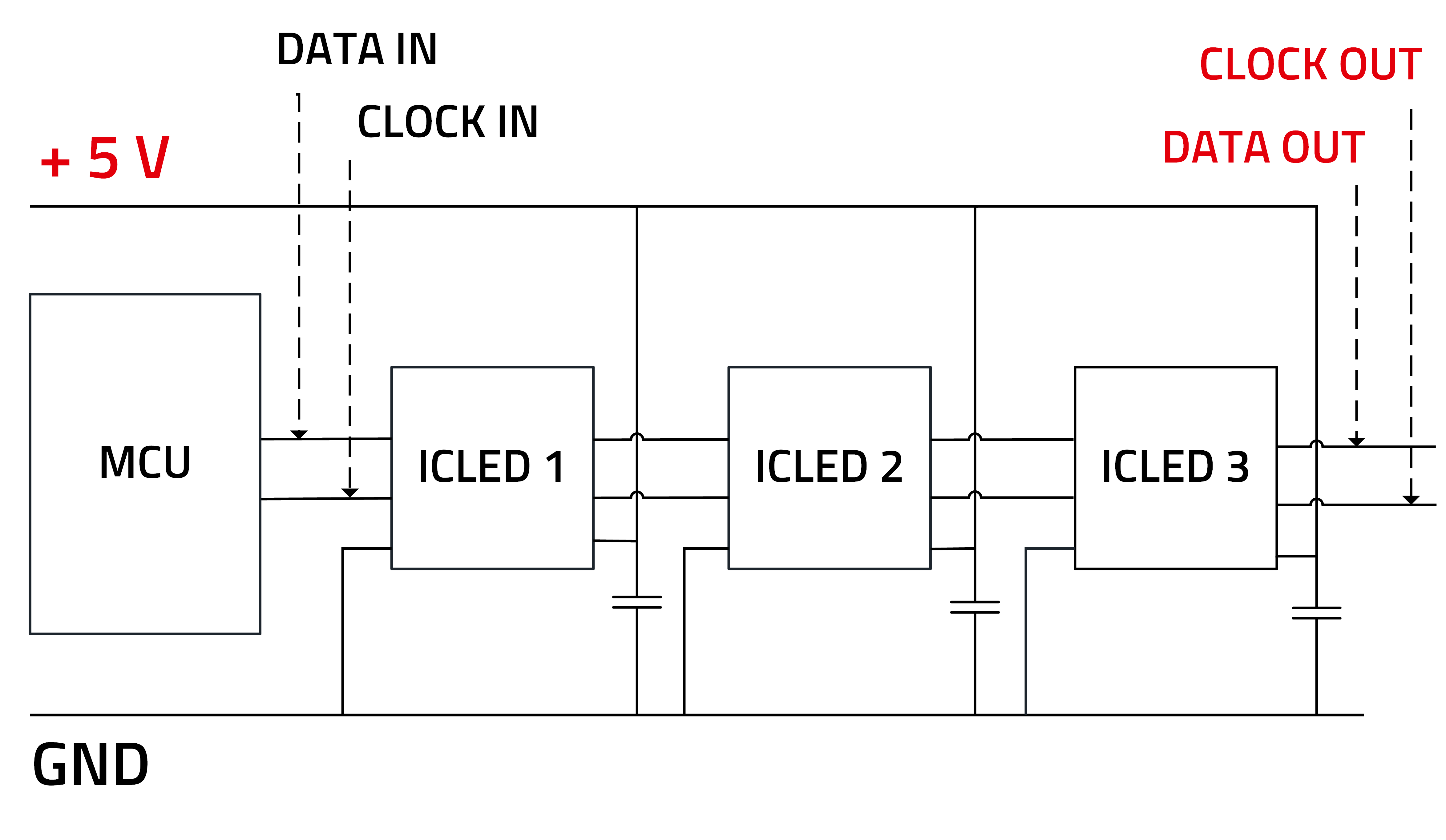

The typical application circuit of an ICLED system is shown in Figure 1. The data signals are generated by the microcontroller unit (MCU), whose data signal line is connected to the DIN pin of the first ICLED. The remaining components are connected to each other in a daisy chain connection. Figure 2 shows that each time a data packet is received by the IC, the data is reduced by 24 bits and the remaining bits are forwarded to the next LED in the chain. If a reset code is detected on the DIN pin of the first IC LED, this means that the transmission of a new data packet has begun.

This data determines the pulse width modulation for each individual red, green and blue LED. This means that the dimming is not controlled by the current intensity - as this would influence the color value - but by switching the current on and off quickly and imperceptibly. If it is known which frequency leads to which color mixing of the pixel for the individual LEDs, any color values and brightnesses can be generated. However, this was precisely the problem: application developers could not easily determine these frequencies and did not receive any help from manufacturers.

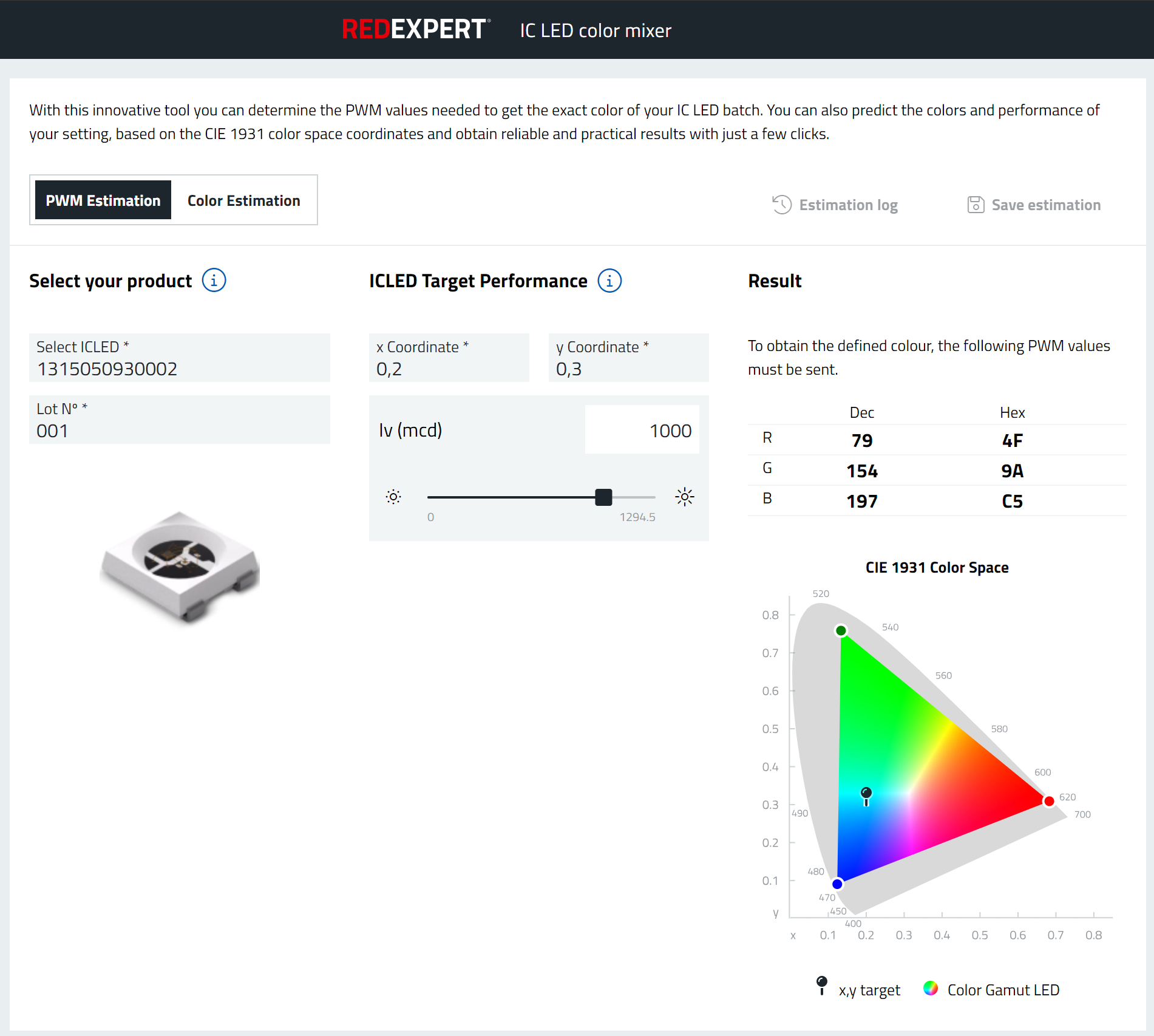

With the ICLED Color Calculator, Würth Elektronik has introduced a new function of its online platform REDEXPERT, which massively expands the possibilities of the lighting and signal solutions with its ICLEDs. For the first time, developers can use this service to easily determine the exact PWM values required to display a specific color value. On the intuitive user interface of the REDEXPERT ICLED Color Calculator (Figure 3), customers select the desired ICLED type as well as color and brightness in the CIE1931 standard color system ("xy color space"). This automatically generates the appropriate digital value for the pulse width modulation of the RGB LEDs installed in the ICLED component, based on the properties of their bin. These values can be transferred directly into the programming of the ICLEDs.

This is made possible by the careful sorting of the ICLEDs during production. There are numerous bins to ensure that only LEDs with uniform color temperature and brightness properties are offered per batch. Thanks to the precision of its quality control and binning, Würth Elektronik's innovative development tool opens up new possibilities for sophisticated LED applications, such as high-quality LED matrix displays and applications that need to be perfectly color-matched to a corporate design.

Particularly in the field of LED matrix displays, the possibility of a true-color display is creating a desire for high frame rates for moving images. This can now be realized with an ICLED variant that has rarely been offered to date and that Würth Elektronik now has in its product range: Dual-Wire ICLEDs.

This technology enables up to 13 times faster data transmission compared to single-wire ICLEDs. They work with fast PWM rates of 20 kHz and produce flicker-free images. Another advantage of the dual-wire ICLEDs is their integrated sleep mode, which reduces power consumption to around 1 µA per ICLED when they are not in operation. This ensures significantly more energy-efficient use, especially in battery-operated systems. In addition, the dual-wire technology offers a freely adjustable clock frequency of the data signal of up to 15 MHz, which enables flexible and fast data transmission. This combination of low power consumption, high adaptability and fast data transmission makes the dual-wire ICLEDs particularly attractive for modern smart lighting applications.

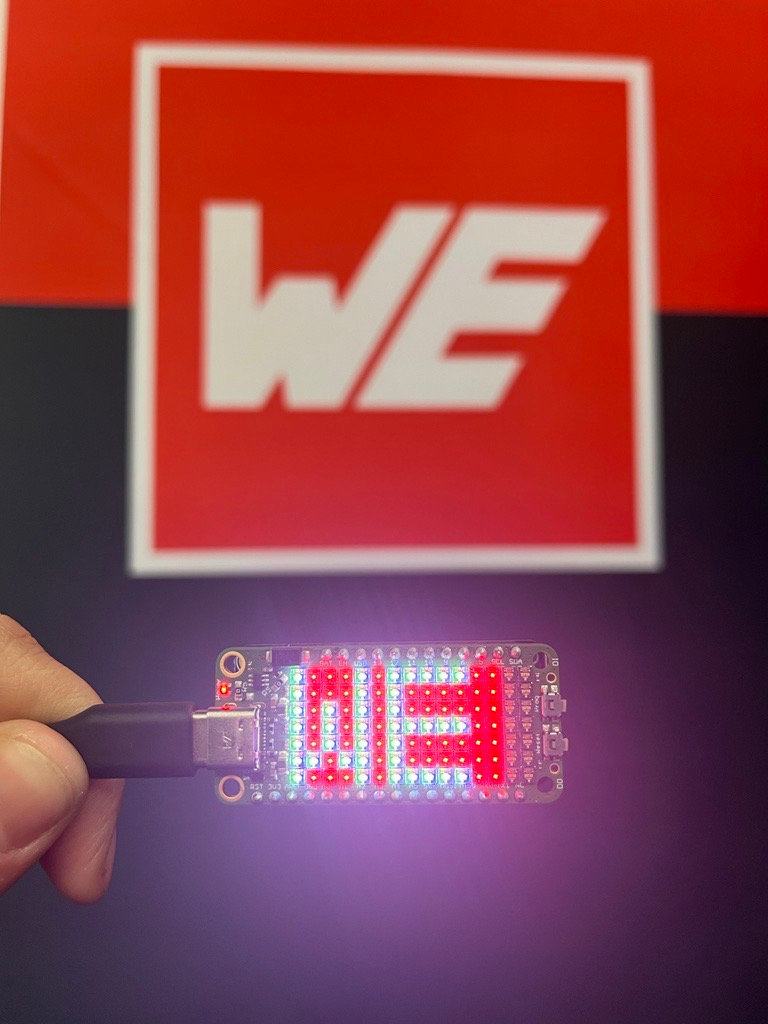

Of course, analog LEDs remain a cheaper alternative - they are around 20 to 30 percent cheaper than ICLEDs - and will not be displaced from simpler applications. However, ICLEDs offer clear advantages for signaling or optically demanding applications. Applications can be implemented much more simply and more economically in terms of the components and cables required. The precise controllability of ICLEDs also opens up new fields of application. There is great potential in adaptive lighting, for example for office lighting that automatically adjusts to weather conditions or the time of day. A color change triggered by a sensor can take on the role of a differentiated proximity alarm, for example as an alternative signal for the hearing impaired. Color-coded signals could also help to provide more information at a glance for health monitors or diagnostic tools. Incidentally, anyone who has had ideas for ICLED applications while reading this article can use the ICLED Featherwing and various sensor and wireless Featherwings from Würth Elektronik for quick prototyping (Figure 5).