Oscillating crystals made high-precision wristwatches affordable for everyone. Now, they have become increasingly important as a reliable time base, including use in GPS positioning.

To learn about oscillating crystals, it’s important to understand their parameters.

The frequency of oscillating crystals, just like in physics, is given in Hertz [Hz]; i.e. the number of vibrations per second. A 10 MHz quartz, for example, vibrates 10,000,000 times per second. Thinner quartz plates vibrate at higher frequencies.

Different applications and circuits require different frequencies of crystals. GPS applications, for example, typically operate at a clock frequency of 26 MHz.

Maintaining a stable frequency is particularly important for systems that exchange data with each other. Should the wrong clock frequency be selected, data loss or connection interruptions can occur.

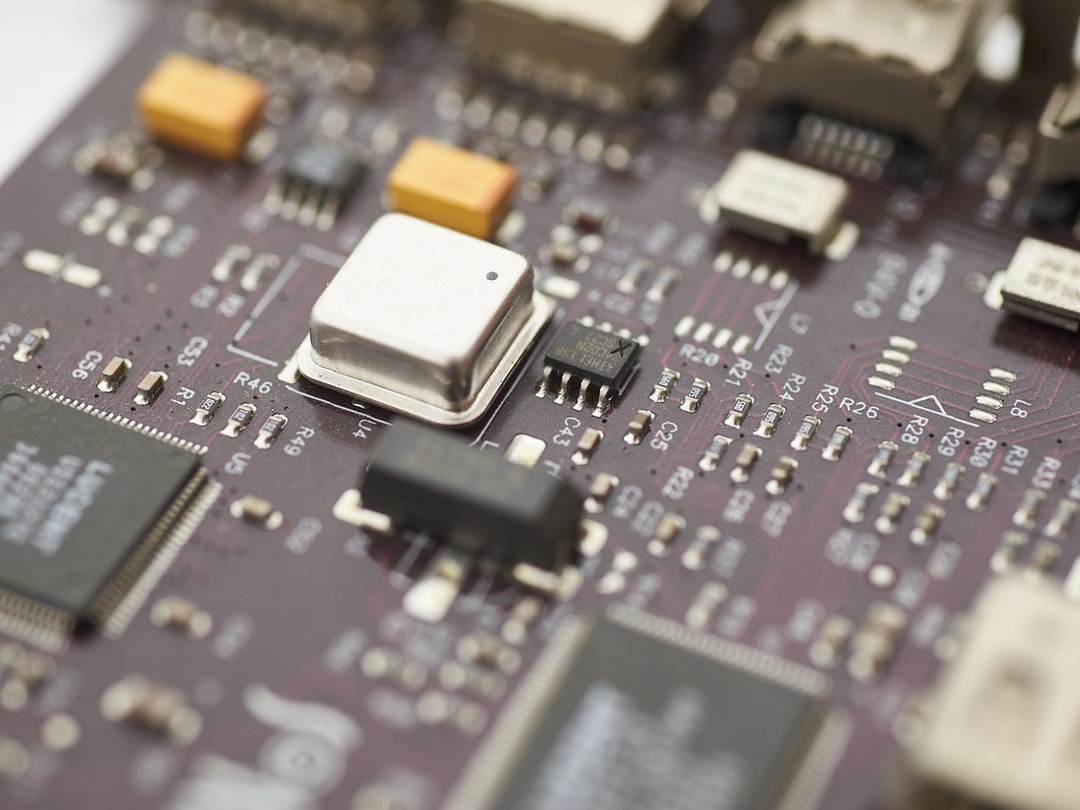

In the past, oscillating crystals were only offered in familiar metal packages, mounted and soldered via two connecting wires to the circuit board. With the advent of surface mount technology (SMT), the components have become smaller and are now mostly ceramic.

Industry standard packages range from 7.0 x 5.0 mm2 to 1.2 x 1.0 mm2. Mini packages are also now available at 1.0 x 0.8 mm2.

Frequency tolerance indicates the extent to which the oscillating crystal deviates from the nominal frequency at room temperature.

Less is not always more; choosing components with a lower frequency tolerance than is required will increase costs with no real benefit.

Frequency stability is the amount the frequency changes over the temperature range. It directly correlates to the cutting angle of the quartz blank.

Frequency stability is one of the most important and application-specific parameters, along with nominal frequency. The values depend on the selected temperature range and can range from ±100 ppm to ±10 ppm (parts per million).

To achieve even better frequency stability, the use of temperature compensated oscillators is recommended, which are also available with their own "oven". These are known as TCXO (Temperature Compensated Crystal Oscillator) or OCXO (Oven Controlled Crystal Oscillator).

Operating temperature range is always listed alongside frequency stability, as these two parameters are related. The temperature range also depends on the application. Common values are -40 to +85 °C for normal commercial devices, or -40 to +125 °C in the automotive sector.

Cost is a factor. Wider temperature ranges and more accurate frequency stability will lead to more expensive components. As with frequency tolerance, it is important to select within parameters required and not increase costs unnecessarily.

Crystals will continue to function outside a specified operating temperature range of for example -20 to +70 °C but will no longer achieve the specified frequency stability.

The load capacitance value indicates how high the capacitance in the oscillator circuit must be to achieve optimum accuracy of the frequency at room temperature.

Capacitance outside of the specifications leads to frequency deviations and in the worst cases, can exceed tolerances. Low load capacitances make the oscillating crystal more unstable, leading to greater frequency deviations, and making it more difficult to achieve nominal frequency accuracy.

In addition to these standard values, there are often other parameters to consider, including aging, equivalent series resistance (ESR), or drive level. To learn more, we recommend the next blog in this 4 article series: All You Need to Know About Oscillating Crystals - Important Additional Parameters.