For DC-DC converter applications, molded power inductors offer smaller footprints and lower profiles due to their magnetic material properties. Current designs require smaller inductors that can operate at higher voltages and currents under extreme thermal conditions.

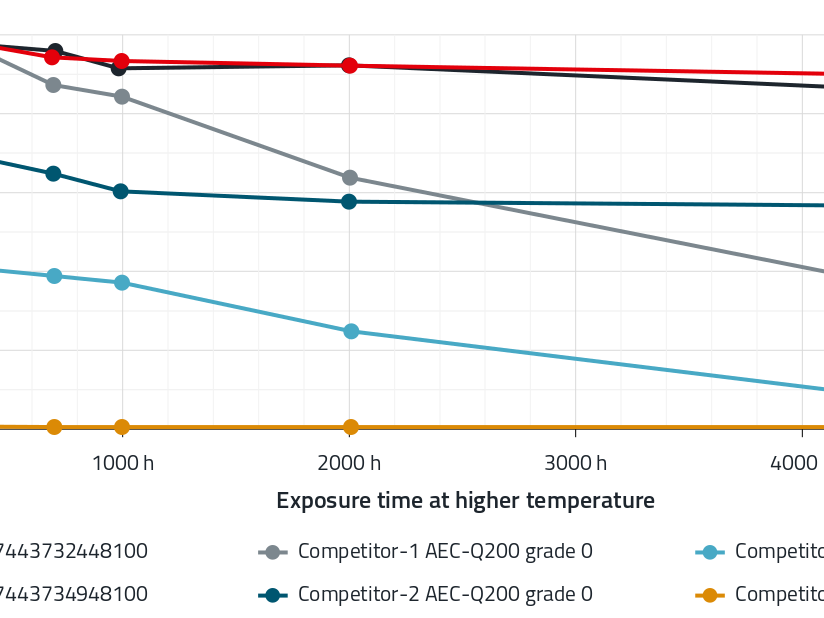

These conditions increase electrical and thermal stresses, leading to higher magnetic core loss over time due to material degradation from the percolation phenomenon.

But what is the percolation phenomenon? What are its repercussions in a molded power inductor? More importantly, how does it affect the long-term performance of a DC-DC converter?

Content:

Download: ANP142