Smaller And Smaller – Better And Better

The steadily increasing integration of electronics determines the everyday life of us humans. That is why, for example, flexible and rigid-flexible circuits are included in very many everyday products. The trend towards ever smaller circuit carriers that are nevertheless ever better adapted to their three-dimensional contours is also unbroken in this area.

Würth Elektronik has been working on solutions to these problems for several years. As part of the solution, stretchable circuit carriers were therefore developed together with the Fraunhofer Institute. By introducing thermoplastic polyurethane as a new base material and designing conductive tracks in e.g. meander or serpentine shapes, properties such as extreme flexibility (up to bending slackness) or elasticity can be created. These properties thus enable completely new fields of application for the integration of electronics in the areas of sensor technology, smart textiles or (soft) robotics. In addition, the soft and skin-friendly properties of polyurethanes make them suitable for use in the medical sector.

Advantages of Würth Elektronik STRETCH.flex Technology

Relevant Parameters for Production-ready PCB Design

Modern printed circuit board solutions are more than just connecting elements. They are the key to progress in electronics. With this in mind, we actively support our customers in development and also offer our own system solutions with electronic functions.

The STRETCH.flex Design Rules include all the important parameters you need to make your project successful:

In our Design Guide you will find an overview of all variants of our flex solutions. In addition, our specialists have summarized valuable design tips for you here. This will help you bring your application to success reliably and safely.

Get Started with Your Layout Faster - Thanks to Standardized Stackups

With these stackups, you automatically use market-customary and cost-optimized standards and avoid expensive custom builds. In addition, high-quality and cost-effective production with shorter delivery times is made possible because stock materials are used and standardized production processes are followed.

Here you will find our standard layer lay-ups for STRETCH.flex in digital form for import into your EDA software and as PDF.

Basically all layouts are designed according to IPC-2223 Use A (Flex-to-install).

Application Example

This cycling jacket by designer Wolfgang Langeder, developed in collaboration with Fraunhofer IZM, contains several stretchable circuit carriers that contribute significantly to interactive safety lighting thanks to the integrated and active sensor-controlled LEDs.

Information can be found in our data sheet.

Due to the increased handling effort during production, the STRETCH.flex technology is about 15 to 25% more expensive than a comparable RIGID.flex PCB.

Yes, applications in the textile sector are generally possible. The polyurethane we use can be laminated onto textile surfaces, but depending on the application, encapsulation is recommended to protect the components (e.g. Glob Top).

Through various research and initial customer projects, we have been able to gain positive experience, especially in the forming, back injection and lamination of the circuits.

The STRETCH.flex boards can be soldered in a reflow process using low-temperature solder. Currently there are no further empirical values when using other soldering methods with low temperature solders, e.g. vapor phase soldering or wave soldering, this must be checked individually. The use of normal SAC solders or generally solders with liquidus temperatures of 145°C is not recommended, as the softening point or melting point of TPU is reached.

Flip chip assembly is possible, but the flip chip process must be considered in more detail. If a solder-based flip chip process is used, a low-temperature solder paste must be used. For adhesive-based flip chip processes (ICA, ACA, NCA), the curing temperature of the adhesive used must match the operating temperatures of the thermoplastic polyurethane.

Standardized printed circuit board production processes are used in the manufacture; traces made only of gold are not possible for process reasons. However, the copper traces can be coated with a gold surface in a wet chemical process.

Currently, we use only copper as a conductive material, but our R&D is currently actively working on builds that use stretchable inks.

We only use clear/milky TPU, but are working on introducing colored TPU.

STRETCH.flex technology is produced in accordance with IATF-certified manufacturing processes, but its use in the automotive sector depends on the actual area of application (e.g. an application in the engine compartment is critical due to the temperatures). Please contact us, we will be happy to advise you.

The production in the production panel results in a max. production length of 420 mm x 570 mm. However, for the realization of larger circuits, these can be laid in a serpentine or meander form.

No, currently this function is not yet offered.

The currently feasible layer structures for STRETCH.flex technology can be found in our Design Rules.

Then feel free to ask this question by email to our product specialists.

Understand Würth Elektronik STRETCH.flex Technology Playfully

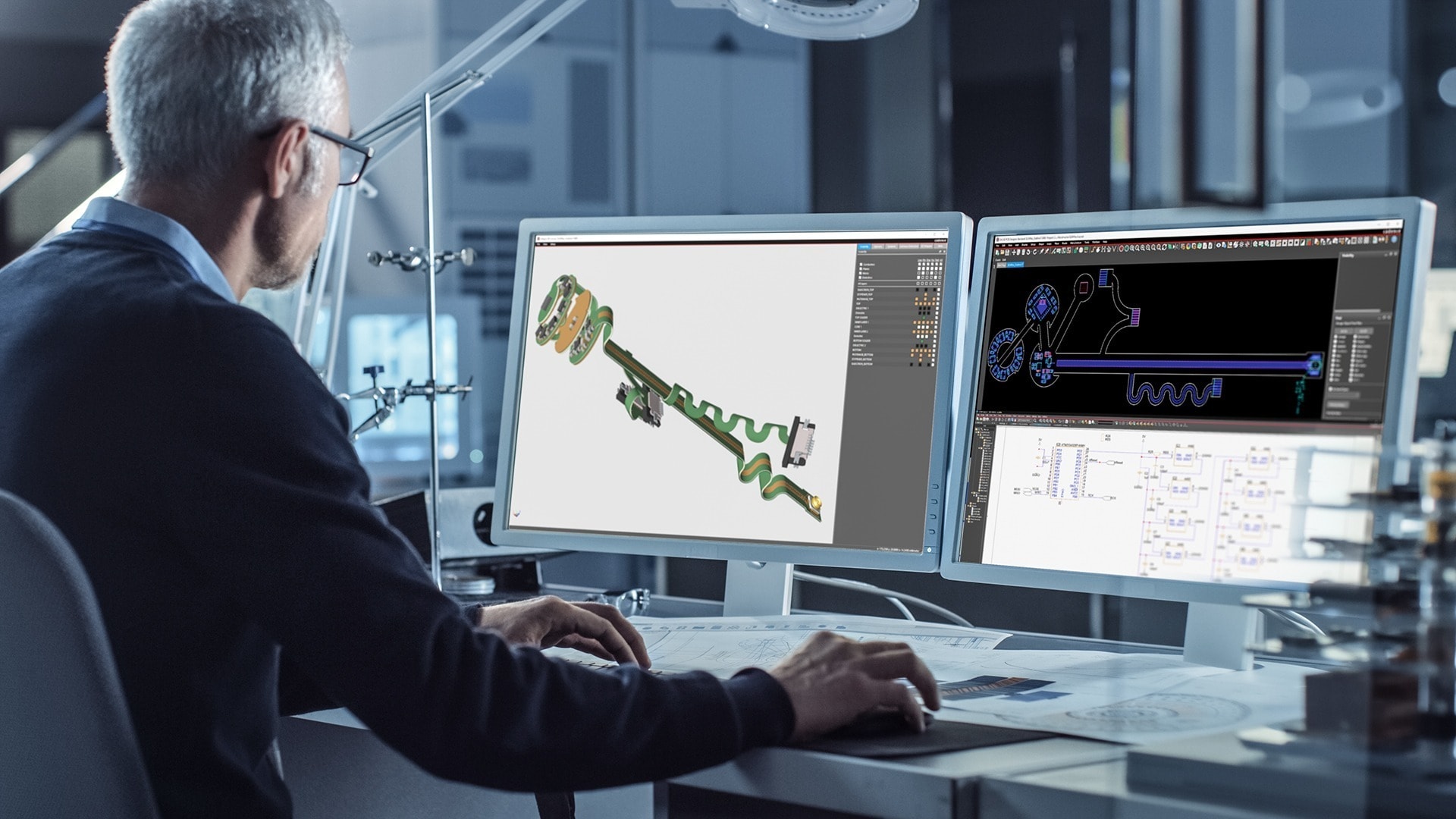

Learn in detail about the possibilities of STRETCH.flex technology in terms of design and applications. The digital PCB sample WE.band shows the practical implementation of stretchable copper conductors in your EDA tool.

STRETCH.flex PCBs

View recordings and presentations of our STRETCH.flex webinars here:

"STRETCH.flex – a stretchable PCB – Introduction"

"STRETCH.flex 2.0 – we stretch the limits of designs!"

"Flexible, stretchable and bending slackness: STRETCH.flex sample WE.band!"

Webinar "STRETCH.flex 2.0 – we stretch the limits of designs!"